Landfill Waste Recycling

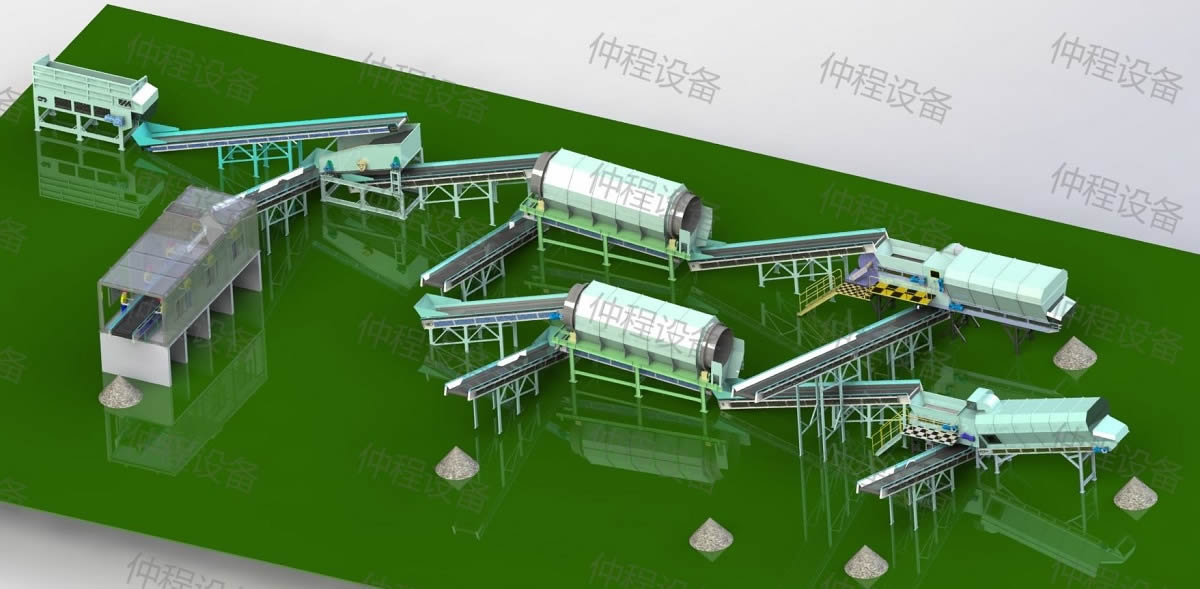

- Treatment process: Feeder,Trommel Screen,Air Drum Separator,Conveyor Belt.

- Throughput: 150t/h

- Raw Material: Landfill Waste

- Finished Material: soil,aggregate,stones, plastic, etc..

- Main Equipment: Feeder,Trommel Screen,Air Drum Separator,Conveyor Belt,etc.

- Case Description

Landfill mining refers to the long-term natural evolution product of waste after being disposed of in landfills. After long-term microbial fermentation and decomposition, the moisture of the waste is relatively large and the content of organic matter is relatively low. If it is excavated and then incinerated, it needs to be screened and sorted first, and the sorted combustibles are used for waste incineration, and other wastes are composted and landfilled according to specific classifications. Landfill waste can be classified into the following categories: humus, plastic film, rigid plastics (which can be divided into a variety of plastics), rubber, magnets, non-ferrous metals, construction waste bricks and tiles, waste glass, wood, textiles and combustibles things etc. They will be effectively recycled, so that these wastes can be turned into commodities which can be accepted by the market, and the recycling of materials will be promoted.

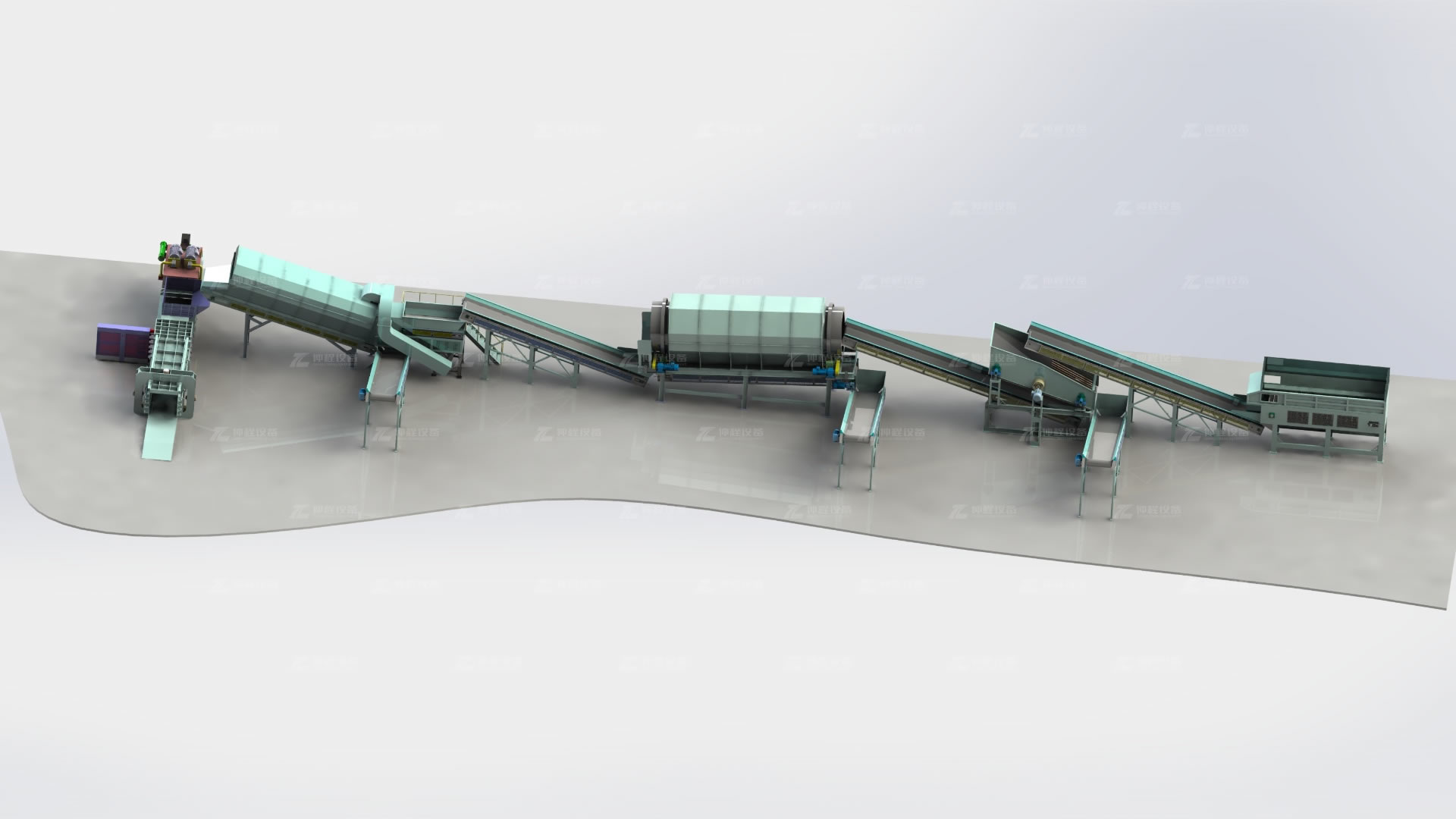

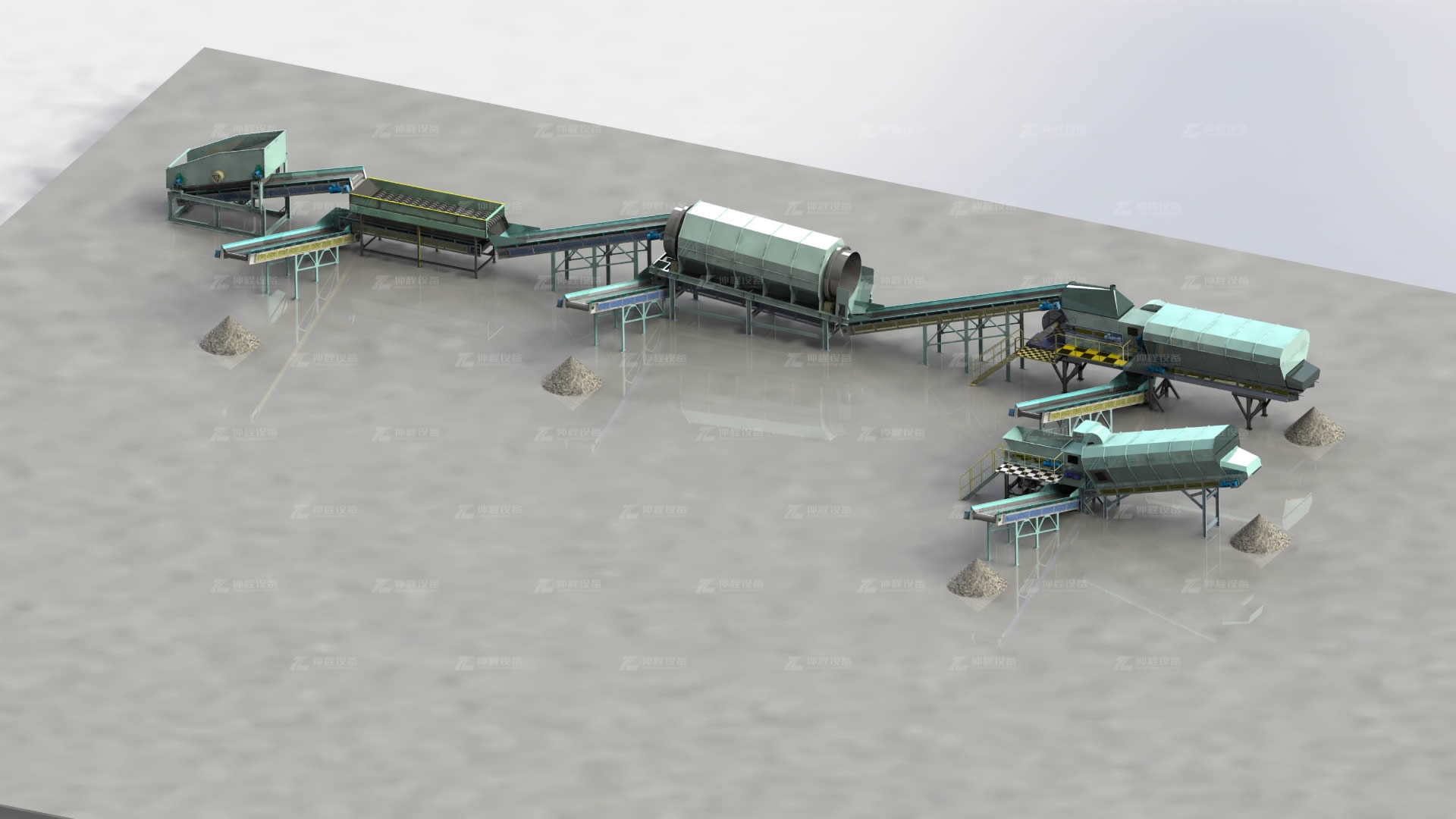

The screening process in landfill mining involves several sequential steps to effectively separate and recover valuable materials from waste. Here's description of each stage:

Landfill Mining Screening Process

1. Initial Waste Sorting

Large Material Separation: At the beginning of the process, large materials such as construction debris, rocks, and oversized items are mechanically sorted out. This step helps prevent damage to subsequent screening equipment.

2. Feeder

Material Feeding: After initial sorting, the remaining waste is fed into the screening system through a feeder. This ensures a consistent flow of material into the subsequent screening stages.

3. Finger Screen

Primary Screening: The waste material passes through a finger screen, which consists of multiple rows of staggered, resilient fingers. These fingers allow smaller materials to pass through while larger items are separated out. The finger screen efficiently breaks up clumps of waste and prepares the material for further separation.

4. Drum Screen

Size Classification: Following the finger screen, the waste undergoes screening in a drum screen (trommel). The drum screen rotates, allowing finer materials to fall through the screen while larger items are conveyed to the end of the drum. This stage further classifies the waste based on size, separating soil, organic matter, and smaller debris from larger recyclables.

5. Air Drum Separator

Air Classification: After the drum screen, the waste stream may pass through a wind separator. This equipment uses airflow to separate lighter materials such as plastics, and textiles from heavier items like aggregate,rubber and stone. The wind separator enhances the purity of recovered materials by removing lightweight contaminants.

6. Magnetic Separator(can be installed at different places in the production line)

Ferrous Metal Recovery: Next, the waste undergoes magnetic separation to recover ferrous metals. Magnetic separators attract and extract ferrous materials from the waste stream, including iron and steel. This step is crucial for recovering valuable metals for recycling purposes.

7. Manual Sorting Platform(can be installed after the feeder)

Final Sorting: The final stage involves manual sorting by trained workers stationed at sorting platforms. They meticulously sort through the remaining waste to remove any remaining contaminants and recover recyclable materials that may have been missed by automated systems. Manual sorting ensures the highest quality of recovered materials and maximizes recycling efficiency.

Advantages of Landfill Waste Recycling Systems

Waste Reduction and Reclamation of Land Resources

Landfill waste recycling systems play a crucial role in waste reduction and the reclamation of valuable land resources. By implementing these systems, we can significantly reduce the volume of waste that ends up in landfills. This reduction not only extends the lifespan of existing landfills but also frees up land that can be repurposed for other beneficial uses. The ability to reclaim land previously used for waste disposal opens up opportunities for urban development, green spaces, and other community projects.

Moreover, the reduction of waste volume through recycling minimizes the need for new landfill sites, preserving natural landscapes and reducing the environmental footprint associated with waste disposal. This aspect of landfill waste recycling is critical for sustainable urban planning and the conservation of natural resources.

Achieving Waste Harmlessness and Environmental Protection

One of the primary advantages of landfill waste recycling systems is the realization of waste harmlessness. These systems are designed to eliminate the pollution caused by landfill waste to the surrounding environment and groundwater. By effectively managing and processing landfill waste, we can significantly reduce the release of harmful substances into the environment.

Through advanced sorting technologies, we can neutralize hazardous components within the waste, transforming them into non-toxic materials. This process not only protects the local ecosystem but also enhances the quality of life for nearby communities. The recycling of landfill waste helps in improving the ecological environment, leading to substantial environmental and social benefits.

Additionally, the implementation of these systems contributes to the mitigation of greenhouse gas emissions. Landfills are known to produce methane, a potent greenhouse gas. By diverting organic waste from landfills and processing it through recycling systems, we can significantly reduce methane emissions, thereby contributing to climate change mitigation efforts.

Resource Recovery and Recycling

Landfill waste recycling systems enable the recovery of valuable resources from waste, promoting a circular economy. Through these systems, materials such as humus, combustibles, and metals can be sorted and processed for reuse. This not only conserves natural resources but also reduces the need for raw material extraction, which is often associated with environmental degradation.

Plastic Products Recycling

The recycling process sorts out plastic products like PVC and PET, which can be repurposed into various useful products. Recycled plastics can be used to produce packaging bags, agricultural water pipes, hot melt adhesives, and even conductive materials. By recycling plastic waste, we can reduce plastic pollution and promote sustainable manufacturing practices.

Utilization of Light Materials

Light materials such as film, cloth, fiber, foam, and sponge can be repurposed as RDF (Refuse Derived Fuel) fuel rods or sent to power plants for energy recovery. This utilization of light materials not only diverts waste from landfills but also contributes to the production of renewable energy, thereby reducing reliance on fossil fuels and lowering carbon emissions.

Composting Organic Waste

The organic waste that passes through the recycling system and remains under the screen can be used as compost. This composting process transforms organic waste into nutrient-rich soil amendments, which can be used in agriculture and landscaping. Composting helps in improving soil health, enhancing crop yields, and reducing the need for chemical fertilizers, thus promoting sustainable agricultural practices.

Recycling of Ferrous Metals

Ferrous metals separated by magnetic separators during the recycling process are recycled and reintroduced into the manufacturing cycle. This recovery of metals reduces the demand for virgin metal extraction, conserves natural resources, and lowers the energy consumption associated with metal production. Recycling ferrous metals also contributes to the reduction of mining-related environmental impacts.