Hydraulic Cone Crusher

-

Production Capacity:

10-600T/H

-

Applicable Industries:

rock quarries, sand and gravel, mining, construction and demolition recycling, construction aggregates, road and railway construction, metallurgy, water conservancy and chemical industry.

-

Power:

45-280KW

-

Core Components:

feature hydraulics , incorporate a tramp metal release, automatic reset and an unblocking feature

-

Place of Origin:

Henan, China

- Product Details

- Characteristics

- Working Principle and Application

- Parameters

Advantages of Hydraulic Cone Crusher

Hydraulic cone crusher has the advantages of high crushing capacity, stable and reliable operation, easy maintenance and operation, flexible application range, environmental protection energy saving, etc. It is an ideal crushing equipment in various industrial sectors and construction fields.

-

01Large crushing ratio and high production efficiency The HPC hydraulic cone crusher combines high speed and stroke to greatly increase its crushing capacity, thus improving the crushing ratio and production efficiency. This allows it to process materials more quickly and meet the needs of mass production.

-

02Less consumption of wearing parts and low operating costs The HPC hydraulic cone crusher has a reasonable structural design, superior crushing principles, and technical parameters, making its operation more reliable and reducing the consumption of wearing parts. This not only reduces maintenance costs but also extends the service life of the equipment.

-

03Laminated crushing, excellent finished product particle shape HPC hydraulic cone crusher adopts a special crushing chamber designed based on the principle of inter-granular lamination and a matching rotation speed so that the material is crushed by multiple extrusions, impacts and bends in the crushing chamber. , thereby obtaining finished products with excellent particle shape. This helps improve the quality of products and meet the different needs of users.

-

04Multiple crushing cavity types, flexible application, and strong adaptability The HPC hydraulic cone crusher provides a variety of crushing cavity types to adapt to product requirements of different particle sizes. This enables the equipment to be flexibly used in various production scenarios to meet the different needs of users.

1. Mining industry: Hydraulic cone crusher is one of the key equipment in the mining crushing production line. It is often used to crush iron ore, non-ferrous metal ore, basalt, granite, limestone, sandstone, pebbles, and other mining rocks.

2. Cement plant: In the cement production process, hydraulic cone crushers are used to crush limestone, clay, and other raw materials to provide required materials for cement manufacturing.

3. Sand and gravel industry: In the sand and gravel aggregate production line, hydraulic cone crushers are used for medium and fine crushing of raw materials to produce sand and gravel aggregates that meet the requirements. They are widely used in construction, highways, railways and other fields.

1. Laminated crushing: The rotation of the motor drives the eccentric shaft to rotate through the pulley or coupling and the cone crusher transmission shaft. The eccentric sleeve on the eccentric shaft forces the crushing cone to rotate around a fixed point. This makes the crushing wall of the crushing cone sometimes approach and sometimes leave the surface of the rolling mortar wall fixed on the adjusting sleeve. The ore is continuously impacted, squeezed, and bent in the crushing cavity, thereby achieving the crushing of the ore.

2. Hydraulic technology: Hydraulic cone crusher is equipped with an advanced hydraulic control system and hydraulic safety system. The hydraulic control system can easily adjust the size of the discharge port to adapt to crushing operations with different particle size requirements. The hydraulic safety system can lift the support sleeve and fixed cone part through the hydraulic cylinder when the machine is overloaded or malfunctioned, automatically removing faulty objects in the crushing chamber and protecting the equipment from damage.

Specification

| Model | Cavity | Standard type | Shorthead type | Capacity (t/h) | Motor Power (kw) | ||

Feeder opening size(mm) | Outlet setting size(mm) | Feeder opening size(mm) | Outlet setting size(mm) | ||||

| HP200 | Coarse | 185 | 19 | 76 | 10 | 145-250 | 132-200 |

| Medium | 125 | 17 | 54 | 6 | 135-235 | ||

| Fine | 95 | 13 | 23 | 6 | 115-220 | ||

| UltrafineFine | 75 | 10 | 10 | 5 | 90-190 | ||

| HP300 | Coarse | 210 | 20 | 75 | 10 | 190-380 | 180-250 |

| Medium | 150 | 15 | 50 | 8 | 175-320 | ||

| Fine | 105 | 10 | 20 | 6 | 145-280 | ||

| UltrafineFine | 80 | 10 | 20 | 6 | 110-240 | ||

| HP400 | Coarse | 250 | 25 | 90 | 10 | 285-560 | 280-355 |

| Medium | 195 | 20 | 50 | 8 | 250-490 | ||

| Fine | 110 | 14 | 40 | 6 | 180-345 | ||

| UltrafineFine | 90 | 10 | 30 | 6 | 135-320 | ||

| HP500 | Coarse | 285 | 25 | 90 | 13 | 400-790 | 355-450 |

| Medium | 200 | 20 | 55 | 10 | 335-610 | ||

| Fine | 133 | 16 | 40 | 8 | 280-460 | ||

| UltrafineFine | 95 | 13 | 35 | 6 | 180-435 | ||

-

Jaw CrusherThe working principle of jaw crusher Although the jaw crusher has various structural types, its working principle is the same, that is, the material is crushed ...Get Quote

Jaw CrusherThe working principle of jaw crusher Although the jaw crusher has various structural types, its working principle is the same, that is, the material is crushed ...Get Quote -

Mobile Impact Crusher PlantThe mobile impact crusher plant is a kind of crushing equipment based on a mobile platform. It uses an impact crusher as the host machine and is usually equippe...Get Quote

Mobile Impact Crusher PlantThe mobile impact crusher plant is a kind of crushing equipment based on a mobile platform. It uses an impact crusher as the host machine and is usually equippe...Get Quote -

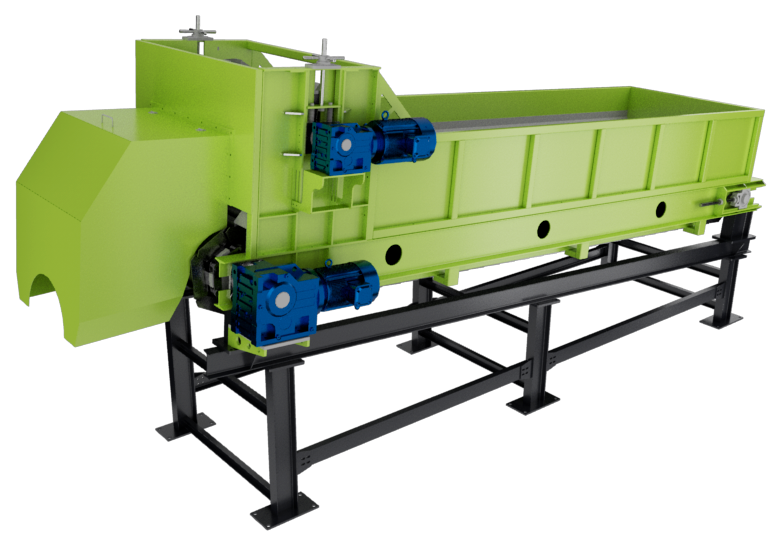

Bag OpenerBag opener or bag opener system is a mechanical device used to automatically open and empty bags containing bulk materials. This system is commonly used in indu...Get Quote

Bag OpenerBag opener or bag opener system is a mechanical device used to automatically open and empty bags containing bulk materials. This system is commonly used in indu...Get Quote -

Impact CrusherImpact crusher is a type of machine designed to reduce large rocks, ores, and other hard materials into smaller, more manageable pieces. This equipment is widel...Get Quote

Impact CrusherImpact crusher is a type of machine designed to reduce large rocks, ores, and other hard materials into smaller, more manageable pieces. This equipment is widel...Get Quote