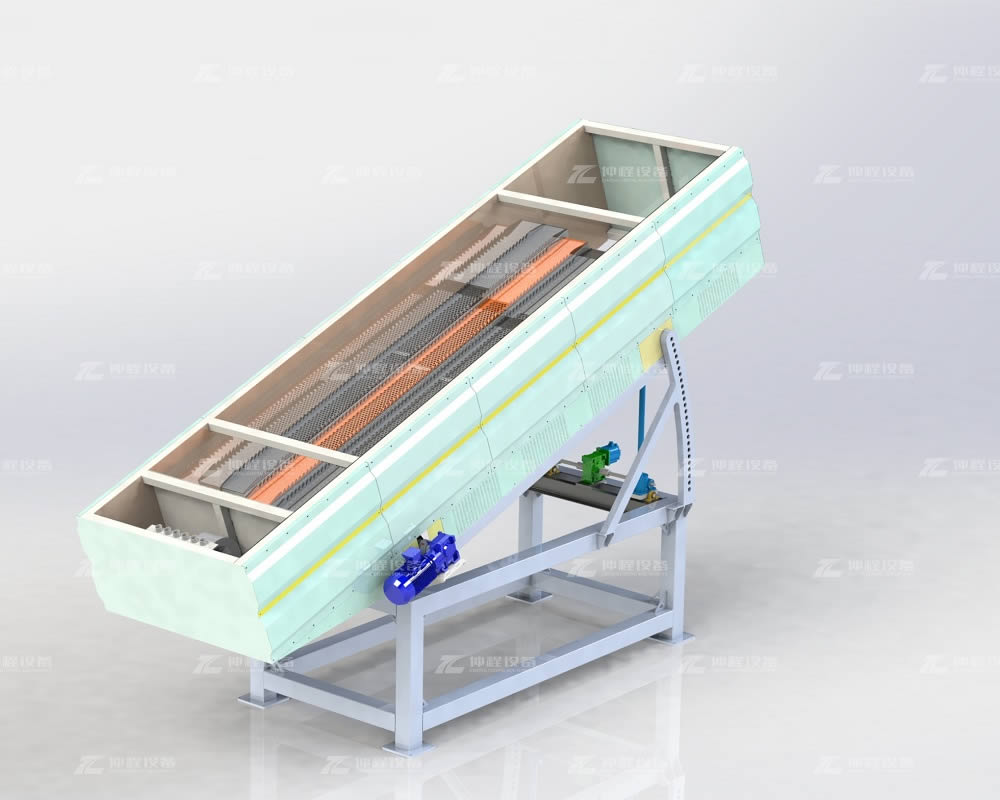

Ballistic Separator

-

Production Capacity:

30~120m³/h

-

Applicable Industries:

MSW;C&D;Single-Stream Recycling、Paper industry

-

Power:

5.5kw-22kw

-

Core Components:

Crankshaft maintenance access. Centralised lubrication system.

-

Place of Origin:

Henan, China

- Product Details

- Characteristics

- Working Principle and Application

- Parameters

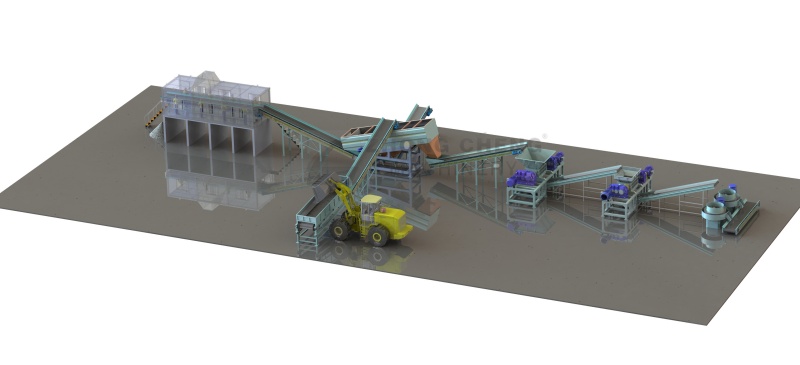

Optimize Your Waste Management and Recycling Processes

High-Efficiency Ballistic Separators for Waste Recycling Centers

Our ballistic separators are the ultimate solution for waste management and recycling industries, designed to separate materials based on their density, shape, and size through precise ballistic movement. This advanced equipment ensures efficient and effective sorting, reducing manual intervention and enhancing recycling rates.

Key Components of a Ballistic Separator

Infeed Conveyor

The infeed conveyor is responsible for transporting mixed waste to the separator. This component ensures a steady and controlled flow of materials into the machine, which is essential for maintaining efficiency and consistency in the sorting process.

Oscillating Deck

The oscillating deck is the heart of the ballistic separator. It is here that the actual separation occurs. The deck oscillates to create a ballistic movement, which sorts materials based on their physical properties.

Paddles

Mounted on the oscillating deck, the paddles provide the necessary motion to separate materials. These paddles are critical for creating the ballistic movement that differentiates materials by density, shape, and size.

Fraction Discharge Points

The sorted materials are collected at different fraction discharge points. These points ensure that 2D and 3D materials are separated into distinct streams, allowing for efficient processing and recycling.

-

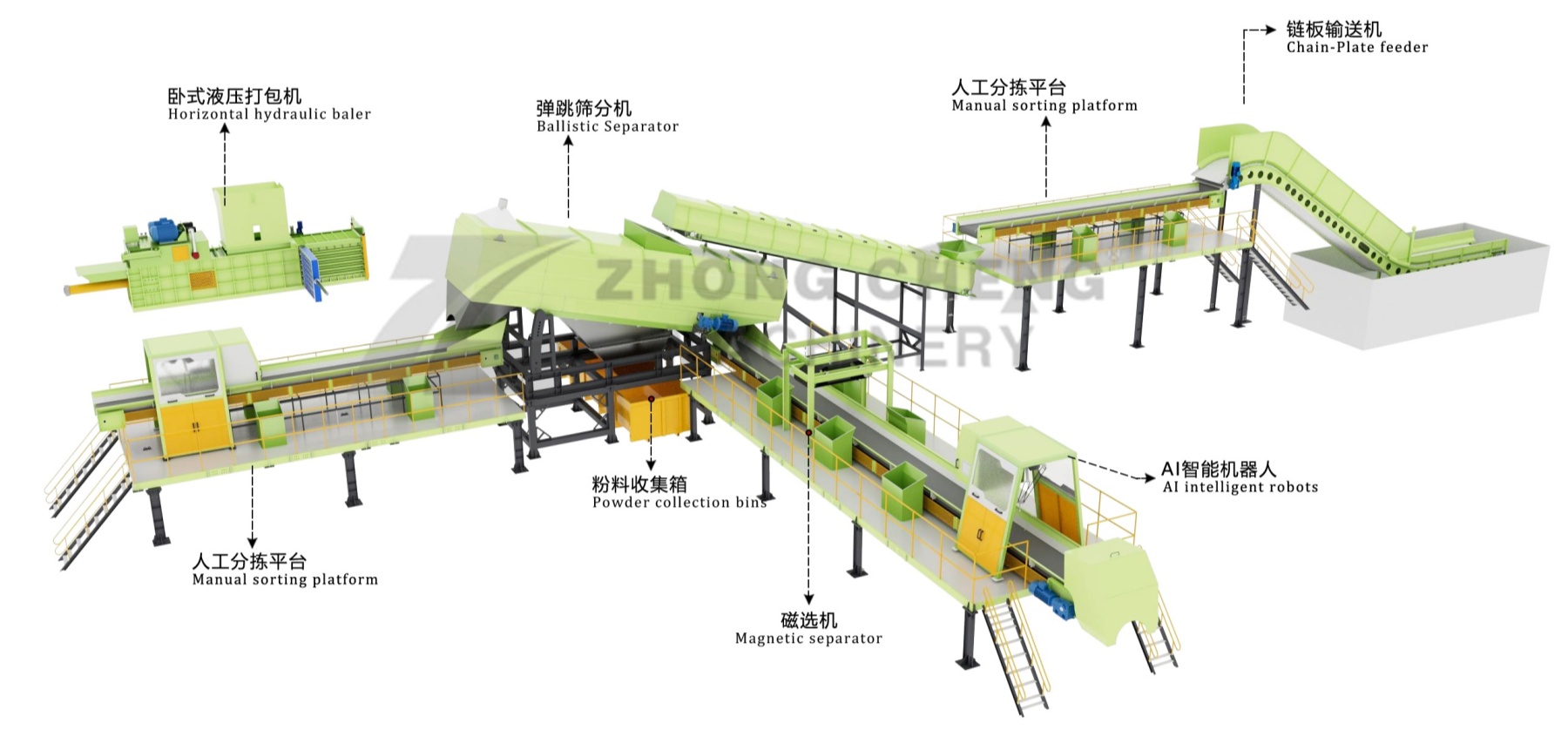

01Efficiency One of the primary benefits of ballistic separators is their efficiency. These machines are capable of processing large volumes of material quickly, significantly reducing the need for manual sorting. This efficiency translates to lower operational costs and higher throughput, making ballistic separators an essential component in modern recycling facilities.

-

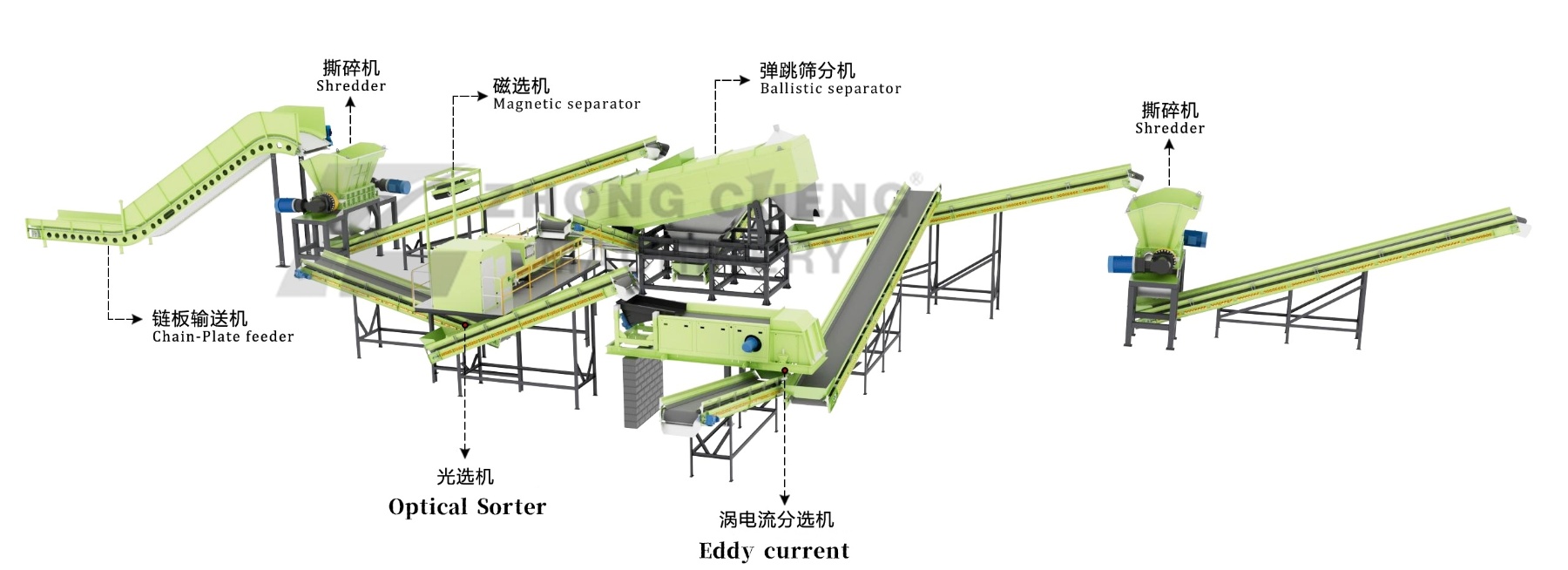

02Versatility Ballistic separators are incredibly versatile, effective for a wide range of materials. They can handle various waste streams, including municipal solid waste (MSW), commercial waste, and recyclables such as plastics, metals, and paper. This versatility ensures that recycling centers can adapt to different types of waste without needing multiple sorting systems.

-

03Automation Integrating ballistic separators into automated sorting systems further enhances their value. Automation reduces the need for manual labor, decreases human error, and increases the overall efficiency of the recycling process. This integration is especially beneficial in large-scale operations where consistency and speed are critical.

-

04Enhanced Recycling Rates By providing a cleaner separation, ballistic separators improve the quality of recycled materials. This enhancement leads to higher recycling rates, as more materials are correctly sorted and processed. Cleaner output also means that the final recycled products are of higher quality, which is crucial for meeting industry standards and market demands.

Operational Mechanism of Ballistic Separators

Feeding Material

Mixed waste or recyclable materials are fed onto the inclined plane of the ballistic separator. The controlled feeding ensures that the machine operates efficiently and effectively.

Ballistic Movement

The inclined plane is equipped with paddles that move the materials upwards. This motion creates a ballistic movement, sorting the materials based on their physical characteristics. Heavy and rolling materials (3D) like flacons, plastic bottles (PET and HDPE), and cans are separated from flat and light materials (2D) like envelopes, trays, and plastic films (LDPE).

Sieved Fraction

Depending on the size of the holes in the screening paddles, the ballistic separator can classify different sizes of underscreen fraction. This sieved fraction typically includes soil, sand, organic waste, and small pieces of recyclables, which are usually not recoverable.

Applications of Ballistic Separators

Recycling Plants

In recycling plants, ballistic separators are used to separate recyclables such as plastics, metals, and paper. This separation ensures that the materials are processed correctly and efficiently, improving the overall recycling rate.

Waste Management

Ballistic separators play a crucial role in waste management by sorting municipal solid waste and reducing landfill waste. By recovering valuable materials, these machines contribute to more sustainable waste management practices.

Composting Facilities

Composting facilities use ballistic separators to remove non-compostable contaminants from organic waste. This removal process is essential for producing high-quality compost that is free from impurities.

Industrial Waste Management

In industrial waste management, ballistic separators handle waste generated from manufacturing and other industrial processes. This handling ensures that recyclable materials are recovered and processed appropriately.

Municipal Solid Waste (MSW) Processing

Ballistic separators are integral to municipal solid waste (MSW) processing. They efficiently separate recyclable materials from household waste, reducing the amount of waste sent to landfills and improving recycling rates.

Technical Aspects and Customization

Parallel Paddles

The ballistic separator, or ballistic sieve, consists of a series of parallel paddles (ranging from 4 to 16, depending on the flow of the incoming material) with orbital motion. These paddles are arranged at a variable angle (15° to 25°) relative to the horizontal plane.

Strong Shaking

The multiple paddles subject the incoming waste mass to strong shaking, more effectively separating the waste than single screen deck solutions. The waste materials, with different physical characteristics (weight, shape, surface), follow different trajectories due to the orbital paddle movement.

Adjustable Angle of Incidence

A rapid adjustment of the paddles' angle of incidence allows for increased separation of heavy or light fractions when processing different materials. Only the set of blades tilts, while the chassis and underlying hoppers remain fixed, preventing dust dispersion.

Handling Different Material Types

Ballistic separators can handle a variety of material types, including single-stream recycling, packaging waste, municipal solid waste, commercial waste, and mixed construction waste. This capability makes them the best choice for effective sorting processes at low cost and high availability.

Why Choose Our Ballistic Separators?

Proven Performance: Trusted by numerous waste recycling centers worldwide.

Custom Solutions: Tailored to fit your specific needs and operational requirements.

Expert Support: Our team of experts provides ongoing support and service.

Low Maintenance: Ensures minimal downtime with easy-to-maintain systems.

High Availability: The best choice for an effective sorting process at low cost and with high availability.

Enhance Your Waste Recycling Process Today

Maximize efficiency and improve the quality of your waste sorting system with our state-of-the-art ballistic separators. Contact us now to request a quote or learn more about our solutions.

| BS04 | BS06 | BS08 | BS10 | BS12 | |

| Paddy Number | 4 | 4 - 6 | 4 - 6 | 4 - 6 | 4 - 6 |

| Paddle length | 5.5m | 5.5m | 5.5m | 5.5m | 5.5m |

| Angle adjustment | 0 – 25° | 0 – 25° | 0 – 25° | 0 – 25° | 0 – 25° |

| Sieve hole size | 20-80 mm | 30-80 mm | 30-80 mm | 30-80 mm | 30-80 mm |

| Fan Number | 2 - 4 | 2 - 4 | 2- 4 | 2 - 4 | 2 - 4 |

| Power | 5.5kw | 7.5kw | 11kw - 15kw | 11kw -18.5kw | 22kw |

| Throughput | 0-30 m³/h | 30-50 m³/h | 50-70 m³/h | 70-90 m³/h | 90-120 m³/h |

-

WindshifterWindshifter (Air Drum Separator ) is the ideal solution for separating all kind of waste types into two fractions, heavy and light. The robust construction and ...Get Quote

WindshifterWindshifter (Air Drum Separator ) is the ideal solution for separating all kind of waste types into two fractions, heavy and light. The robust construction and ...Get Quote -

Mini Copper Wire GranulatorThe copper wire granulator machine is a device specially used to process waste wires and cables. Its main function is to separate the copper and plastic in the ...Get Quote

Mini Copper Wire GranulatorThe copper wire granulator machine is a device specially used to process waste wires and cables. Its main function is to separate the copper and plastic in the ...Get Quote -

Recycling Finger ScreensFinger screen is a type of screening equipment used to separate materials based on size. Unlike traditional screens, finger screens consist of a series of paral...Get Quote

Recycling Finger ScreensFinger screen is a type of screening equipment used to separate materials based on size. Unlike traditional screens, finger screens consist of a series of paral...Get Quote -

Vibrating ScreenVibrating screen is a mechanical device used to separate materials into different sizes and grades by vibrating them through a mesh or screen. This equipment is...Get Quote

Vibrating ScreenVibrating screen is a mechanical device used to separate materials into different sizes and grades by vibrating them through a mesh or screen. This equipment is...Get Quote