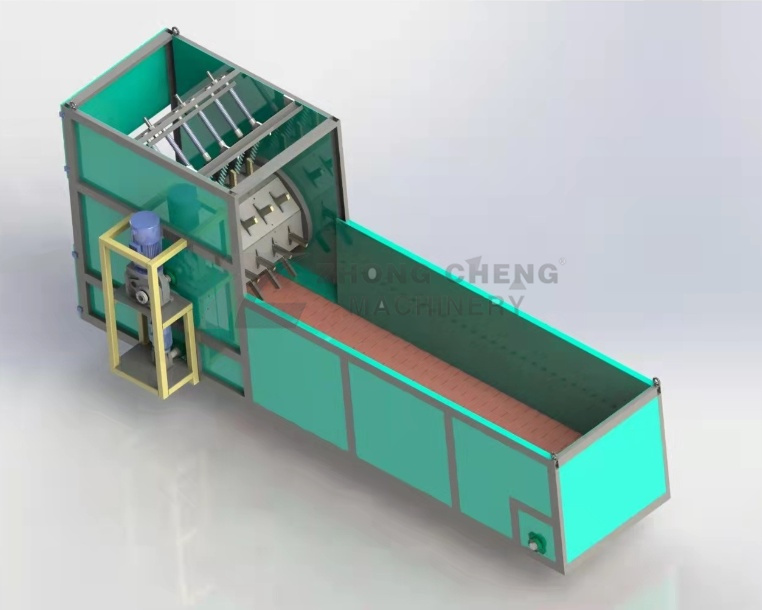

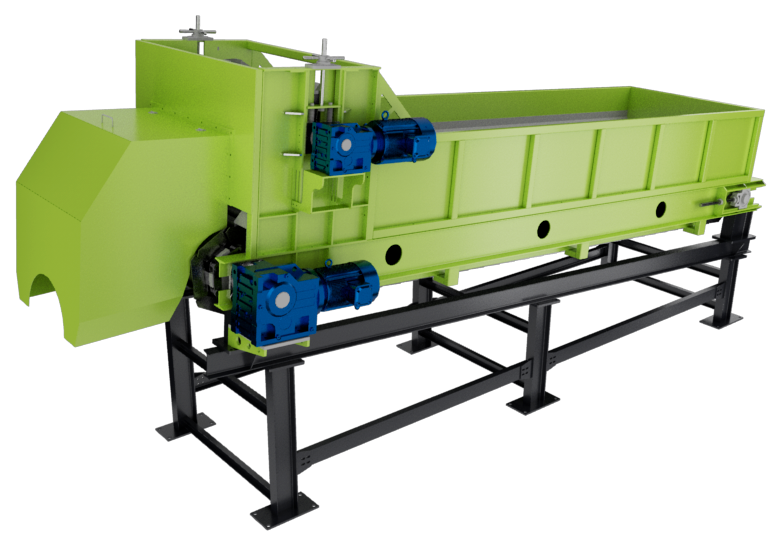

Bag Opener

-

Production Capacity:

60-100m³/h

-

Applicable Industries:

waste management facilities, recycling plants, and large commercial environments.

-

Power:

22-55Kw

-

Core Components:

CE / ISO:9001

-

Place of Origin:

Henan, China

- Product Details

- Characteristics

- Working Principle and Application

- Parameters

The use of plastic and other types of bags for waste disposal is widespread across urban areas. These bags often contain mixed materials, including recyclable and non-recyclable waste. Manually opening these bags is not only labor-intensive but also poses health and safety risks to workers. A Bag Opener Machine addresses these issues by providing a safe, efficient, and reliable solution for handling bagged waste.

How Bag Opener Machines Work

Bag Opener Machines are designed with advanced technology to handle various types of waste bags. Here is a step-by-step breakdown of how these machines operate:

Loading

Waste bags are fed into the machine via a conveyor belt or a hopper. The design ensures continuous feeding, allowing for a steady flow of waste materials.

Cutting and Opening

The machine is equipped with sharp blades or teeth that pierce and cut the bags open. This action is controlled to minimize damage to the waste materials inside, ensuring they remain intact for further processing.

Separation

Once the bags are opened, the waste is gently discharged onto another conveyor belt for sorting. The design minimizes spillage and ensures that all materials are directed toward the sorting line.

Sorting

After the waste is released from the bags, it can be sorted using additional equipment, such as screens, magnets, and optical sorters, to separate recyclables from non-recyclables.

Disposal and Recycling

The sorted materials are then either recycled or disposed of appropriately, depending on their nature. Recyclables are processed for reuse, while non-recyclables are sent to landfills or incinerators.

-

01Fully automatic processing, no manual operation

-

02Strong compatibility, suitable for use with a variety of existing equipment

-

03Rugged loading end design for convenience and durability

-

04Strong and durable, no garbage overflow

Bag Opener Machines are used in various settings, each with specific waste management needs:

1. Municipal Waste Management Facilities

In urban areas, municipal waste management facilities benefit greatly from Bag Opener Machines. These machines streamline waste processing, allowing for efficient handling of household waste.

2. Recycling Plants

Recycling plants use Bag Opener Machines to facilitate the separation of recyclable materials from mixed waste. The machines ensure that recyclables are efficiently extracted and processed for reuse.

3. Industrial Waste Processing

Industrial waste often comes in large bags that require mechanical opening for effective processing. Bag Opener Machines provide the necessary power and precision for handling industrial waste bags.

4. Commercial Waste Management

Commercial establishments, such as shopping malls and office buildings, generate significant waste that needs to be managed efficiently. Bag Opener Machines help streamline the process, ensuring waste is handled safely and effectively.

| BO12 | BO14 | BO16 | BO18 | |

| Width | 1200mm | 1400mm | 1600mm | 1800mm |

| Number of rotors | Two | Two | Two | Two |

| Speed of the main rotor | 0-25 rpm | 0-25 rpm | 0-25 rpm | 0-25 rpm |

| Speed of second rotor | 0-5 rpm | 0-5 rpm | 0-5 rpm | 0-5 rpm |

| Power | 15+5.5kw | 15+5.5kw | 15+7.5kw | 15+7.5kw |

| Throughput | 10-30m³/h | 20-50m³/h | 40-80m³/h | 60-100m³/h |

-

Hydraulic Cone CrusherHydraulic Cone Crusher integrates machinery, hydraulic pressure, electrics, automation, and intelligent control, which can be used for medium crushing, fine cru...Get Quote

Hydraulic Cone CrusherHydraulic Cone Crusher integrates machinery, hydraulic pressure, electrics, automation, and intelligent control, which can be used for medium crushing, fine cru...Get Quote -

Jaw CrusherThe working principle of jaw crusher Although the jaw crusher has various structural types, its working principle is the same, that is, the material is crushed ...Get Quote

Jaw CrusherThe working principle of jaw crusher Although the jaw crusher has various structural types, its working principle is the same, that is, the material is crushed ...Get Quote -

Double-Shaft ShredderThe Double-shaft shredder is a widely used industrial shredder that efficiently processes various mixed waste materials, such as construction waste, industrial ...Get Quote

Double-Shaft ShredderThe Double-shaft shredder is a widely used industrial shredder that efficiently processes various mixed waste materials, such as construction waste, industrial ...Get Quote -

Spring Cone CrusherSpring cone crushers are generally used in the medium and fine crushing links of mine crushing, and are mainly used in the secondary crushing and tertiary crush...Get Quote

Spring Cone CrusherSpring cone crushers are generally used in the medium and fine crushing links of mine crushing, and are mainly used in the secondary crushing and tertiary crush...Get Quote