Waste Feeder

-

Production Capacity:

ZC60-170m³/h

-

Applicable Industries:

MSW,Landfill,Organic,C&D waste. It can also be used as a buffer silo to temporarily store materials.

-

Power:

15/22.5kw

-

Core Components:

Sieve plate、PLC

-

Place of Origin:

Henan, China

- Product Details

- Characteristics

- Working Principle and Application

- Parameters

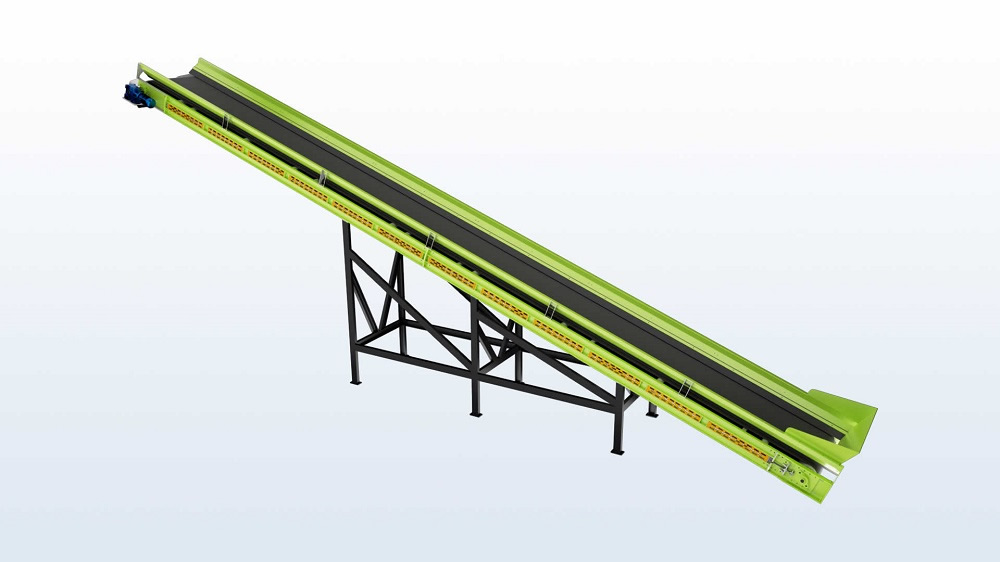

Waste Feeders are equipment commonly used in municipal solid waste recycling operations to control the flow of materials into the recycling process. They are designed to handle a variety of materials such as C&D waste,wood,paper, plastics, glass, and metals. Feeders can be used to regulate the amount of material being fed into the process, prevent jamming or clogging, and ensure a consistent feed rate. They can be automated or manually controlled, and can be integrated with other recycling equipment such as shredders, crushers, or balers.

Waste feeder is also called waste feeding machine, or plate conveyor feeder, this equipment is often combined with bin feeder to form an integrated machine, including conveying, distributing or bag opening functions

-

01Reinforced side-wall panels and heavy duty construction to maximize durability and uptime

-

02Reinforced load side and flared back walls for ease of loading and durability, with minimal spillage

-

03Increases throughput and system capacity up to 20%/Provides a consistent material feed into the system

-

04Maximizes system sorting and screen efficiency/Frees up loader operator to perform other tasks

It is composed of power unit (motor), drive shaft, roller, tensioner, sprocket, chain, bearing, lubricant, chain plate, etc. There are two main parts of material conveying: the chain, which uses its cyclic reciprocating motion to provide traction power; and the metal plate, as the carrier in the conveying process. The principle is to use a series of chains fixed on the traction chain to provide traction, and use metal plates as the carrier to lead the material to be transported in a horizontal or inclined direction.

Electric Drive System

Variable Speed Control

Optional Feed-In Heights

Direct and Remote Grease Options

| CPFD12 | CPFD14 | CPFD16 | CPFD18 | CPFD20 | |

| Width | 1200mm | 1400mm | 1600mm | 1800mm | 2000mm |

| Length | 6/8/10m | 6/8/10m | 6/8/10m | 6/8/10m | 6/8/10m |

| Speed | <0.1m/s | <0.1m/s | <0.1m/s | <0.1m/s | <0.1m/s |

| Distributor Width | 1200mm | 1400mm | 1600mm | 1800mm | 2000mm |

| Distributor Dia | 0.6/0.8/1.2m | 0.6/0.8/1.2m | 0.6/0.8/1.2m | 0.6/0.8/1.2m | 0.6/0.8/1.2m |

| Power | 15/22.5kw | 15/22.5kw | 15/22.5kw | 15/22.5kw | 15/22.5kw |

| Throughput | 20-30m³/h | 30-40m³/h | 40-50m³/h | 50-60m³/h | 60-70m³/h |

-

Vibrating FeederA vibrating feeder is a mechanical device used to convey materials, typically in bulk, from one location to another in a controlled manner. This equipment is co...Get Quote

Vibrating FeederA vibrating feeder is a mechanical device used to convey materials, typically in bulk, from one location to another in a controlled manner. This equipment is co...Get Quote -

Apron FeedersApron Feeder is a conveyor manufactured from steel plates driven by steel chains wearing on steel surfaces. They are a robust design manufactured for durability...Get Quote

Apron FeedersApron Feeder is a conveyor manufactured from steel plates driven by steel chains wearing on steel surfaces. They are a robust design manufactured for durability...Get Quote -

Conveyor BeltGarbage conveyor/Trash conveyor belt system is a processing line to classify paper, plastic, metal, glass, and organic matter and realize the recycling of rubb...Get Quote

Conveyor BeltGarbage conveyor/Trash conveyor belt system is a processing line to classify paper, plastic, metal, glass, and organic matter and realize the recycling of rubb...Get Quote -

Waste FeederWaste feeder was specially designed to optimize municipal solid waste sorting systems. The Drum Feeder ensures that your sorting system, baler or shredder has a...Get Quote

Waste FeederWaste feeder was specially designed to optimize municipal solid waste sorting systems. The Drum Feeder ensures that your sorting system, baler or shredder has a...Get Quote