Apron Feeders

-

Production Capacity:

60-500T/H

-

Applicable Industries:

Bush conveyor chains allow flows of even heavy and large materials to be transported with ease.

-

Power:

15-45 kW

-

Core Components:

CE / ISO:9001

-

Place of Origin:

Henan, China

- Product Details

- Characteristics

- Working Principle and Application

- Parameters

An apron feeder is a crucial component in various industrial applications, especially in the field of waste recycling systems. Designed to handle a wide range of materials, from heavy, abrasive substances to light and fragile items, apron feeders are indispensable in ensuring efficient and continuous material flow.

This equipment is mainly used for waste feeding.Apron feeders provide reliable means of controlling the feed rate to prevent surge loads to the primary crushers or other plant equipment .an apron feeder is run at very low speeds and at a Controlled feed rate as it absorbs the impact loads of the material falling from a dump truck or a front -end loader.Apron feeders are of rugged, heavy duty construction and designed to handle larger feed sizes。

-

01Robust Construction One of the standout features of apron feeders is their robust construction. These feeders are built with heavy-duty steel components, including overlapping metal plates or pans mounted on sturdy chains or conveyor belts. This construction ensures that apron feeders can withstand the harshest conditions and handle the toughest materials without significant wear and tear.

-

02Versatile Application Apron feeders are known for their versatility. They are capable of handling a diverse range of materials, including municipal solid waste, industrial waste, construction and demolition debris, and various types of recyclable materials. This versatility makes them a preferred choice for waste recycling facilities aiming to optimize their processing operations.

-

03Controlled Material Flow The controlled material flow provided by apron feeders is critical for the efficiency of waste recycling systems. By ensuring a consistent and uniform feed, apron feeders help prevent blockages and reduce downtime, thereby enhancing the overall productivity of the recycling process.

-

04Smart Monitoring Systems The integration of smart monitoring systems in apron feeders allows for real-time tracking of performance metrics. These systems can detect issues such as excessive wear, chain tension, and motor performance, enabling predictive maintenance and minimizing the risk of unexpected failures.

Apron Feeders are designed to handle large lumps and where no fines removal is required or where fines are removed by a separate Scalper. When the feed material is wet, sticky or clay like, the Apron Feeder is the machine to select. Generally, the Apron Feeder can be installed in a horizontal or inclined position. The high inclination also allows to build compact installations and to reduce the length of the Apron Feeder keeping the investment costs low.

Municipal Solid Waste (MSW) Processing

In municipal solid waste (MSW) processing, apron feeders play a vital role in transporting mixed waste from collection points to sorting and processing units. Their ability to handle large volumes of waste efficiently makes them essential for municipal recycling facilities that deal with a constant influx of waste materials.

Industrial Waste Management

For industrial waste management, apron feeders are used to manage and transport bulky and abrasive industrial by-products. These feeders are designed to handle heavy-duty tasks, ensuring that industrial waste is fed consistently into processing equipment such as shredders and grinders.

Construction and Demolition (C&D) Debris Recycling

In the recycling of construction and demolition debris, apron feeders are indispensable. They handle materials such as concrete, wood, metal, and asphalt, feeding them into crushers and screens for further processing. The robust design of apron feeders ensures that they can handle the heavy and abrasive nature of C&D debris without significant maintenance issues.

Why Our Apron Feeder?

Easily Handles Problematic Feeds

Our apron feeders are designed to manage challenging materials, including large feed sizes and wet, sticky, clay-like substances. This capability ensures smooth operations in your processing plant under the most demanding conditions.

Rugged, Heavy-Duty Construction

Built to last, our apron feeders feature heavy-duty construction that withstands harsh conditions and heavy loads. This durability makes them ideal for mining and recycling applications where long-term reliability is essential.

Slow Motion Creates Minimal Wear

Operating at a slower pace, our apron feeders experience minimal wear and tear, extending the lifespan of components and reducing maintenance needs. Even under severe conditions, they deliver consistent performance with low maintenance requirements.

Allows Better Control on the Feed Rate

Our apron feeders provide a reliable means of controlling the feed rate, preventing surge loads to the primary crusher or other plant equipment. This control maintains the efficiency of your entire processing system.

Designed for Mining and Recycling Applications

Engineered with a commitment to quality, our apron feeders are heavy-duty and robust, ensuring maximum uptime and a long service life. Their superior performance and reliability make them ideal for mining and recycling applications.

| EXTERNAL CONVEYOR WIDTH | LOADING WIDTH | |||

| EUROPE (MM) | USA | EUROPE (MM) | USA | |

| 1500P | 1 481 | 58’’ | 1 181 | 47’’ |

| 1800P | 1 741 | 68’’ | 1 441 | 57’ |

| 2100P | 2 086 | 82’’ | 1 786 | 70’’ |

| 2250P | 2 250 | 88’’ | 1 950 | 76’’ |

-

Vibrating FeederA vibrating feeder is a mechanical device used to convey materials, typically in bulk, from one location to another in a controlled manner. This equipment is co...Get Quote

Vibrating FeederA vibrating feeder is a mechanical device used to convey materials, typically in bulk, from one location to another in a controlled manner. This equipment is co...Get Quote -

Waste FeederWaste feeder was specially designed to optimize municipal solid waste sorting systems. The Drum Feeder ensures that your sorting system, baler or shredder has a...Get Quote

Waste FeederWaste feeder was specially designed to optimize municipal solid waste sorting systems. The Drum Feeder ensures that your sorting system, baler or shredder has a...Get Quote -

Apron FeedersApron Feeder is a conveyor manufactured from steel plates driven by steel chains wearing on steel surfaces. They are a robust design manufactured for durability...Get Quote

Apron FeedersApron Feeder is a conveyor manufactured from steel plates driven by steel chains wearing on steel surfaces. They are a robust design manufactured for durability...Get Quote -

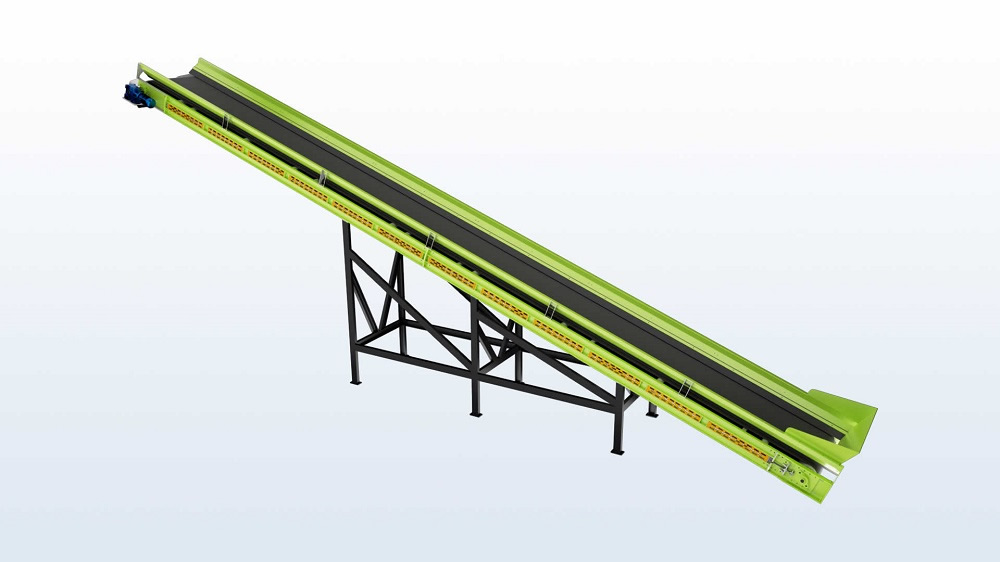

Conveyor BeltGarbage conveyor/Trash conveyor belt system is a processing line to classify paper, plastic, metal, glass, and organic matter and realize the recycling of rubb...Get Quote

Conveyor BeltGarbage conveyor/Trash conveyor belt system is a processing line to classify paper, plastic, metal, glass, and organic matter and realize the recycling of rubb...Get Quote