Mobile Impact Crusher Plant

-

Production Capacity:

60-500T/H

-

Applicable Industries:

rock quarries, sand and gravel, mining, construction and demolition recycling, construction aggregates, road and railway construction, metallurgy, water conservancy and chemical industry.

-

Power:

45-300KW

-

Core Components:

Blow bars/Breaker plate liners/Frame liners/Rotor

-

Place of Origin:

Henan, China

- Product Details

- Characteristics

- Working Principle and Application

- Parameters

Advantages of Mobile Impact Crusher

The mobile impact crushing plant has broad application prospects in the field of crushing operations due to its high flexibility, efficient crushing capacity, wide adaptability, cost saving, environmental protection performance, and easy operation.

Mobile Impact Crusher of Application

Mining: In the mining industry, mobile impact crushing stations are often used to crush ore. Due to its strong mobility, it can be easily moved along with the mining progress of the mine, making the crushing operation more efficient and convenient.

Construction waste disposal: With the acceleration of urbanization, the disposal of construction waste has become a big problem. The mobile impact crushing station can crush construction waste into recycled aggregates of different sizes and specifications, realizing the resource reuse of construction waste, which is of great significance to environmental protection and sustainable development.

-

01High flexibility: The mobile impact crushing station adopts an integrated design and can be easily moved to different working sites without complicated installation and disassembly processes. This makes it extremely flexible when handling materials such as construction waste, rocks, or minerals, and can quickly adapt to different working environments.

-

02Efficient crushing capacity: The impact crusher adopts the principle of impact crushing to efficiently crush materials and produce finished products with better particle size. At the same time, it has a high crushing ratio and crushing efficiency, which can meet the needs of different users for material particle size.

-

03Strong adaptability The mobile impact crushing plant can handle many types of materials, including medium hardness and brittle materials, such as limestone, gypsum, coal, etc. Its wide applicability makes it play an important role in different industries and fields.

-

04Cost saving: This equipment can be driven directly to the site for crushing operations, eliminating the need for material transportation, and thereby reducing transportation costs. At the same time, its integrated design reduces the equipment footprint and infrastructure costs, further reducing investment costs.

Impact Type Mobile Crusher Plants – Low Production Cost

First, raw materials (such as ores, rocks, construction waste, etc.) are fed into the silo of the mobile impact crushing station through forklifts, excavators, and other equipment. These raw materials then enter the screening feeder, where the smaller part of the raw materials will leak directly through the screen holes and be directly formed into mounds or further processed by the excavating belt conveyor.

Materials with larger particle sizes continue to enter the impact crusher through the screening feeder. In the impact crusher, the motor drives the rotor to rotate at high speed through the triangle belt. The plate hammer on the rotor radiates under the action of centrifugal force. When the material enters the rotating range of the plate hammer, it is impacted by the high-speed rotating plate hammer. The material is thrown to the impact plate along the tangential direction of the plate hammer for impact. This impact process causes the material to be continuously impacted and squeezed in the crushing cavity, causing damage to its internal organization, thereby achieving crushing.

Jaw-Type Mobile Crusher Plant – Primary Crushing

| SMC Impact crusher | SMC1010PFS | SMC1210PFS | SMC1214PFS | |

| Transport size | ||||

| Length(mm) | 10800 | 12200 | 12500 | |

| Width(mm) | 2480 | 2743 | 2900 | |

| Height(mm) | 4170 | 4200 | 4200 | |

| Alex weight(kg) | 15900 | 17200 | 22100 | |

| King pin weight(kg) | 11300 | 14300 | 17500 | |

| Impact crusher | ||||

| Model | PF1010 | PF1210 | PF1214 | |

| Feed opening(mm) | 400X1080 | 400X1080 | 400X1080 | |

| Vibrating screen | Vibrating screen | |||

| Model | 4YK1235 | 4YK1545 | 4YK1548 | |

-

Hydraulic Cone CrusherHydraulic Cone Crusher integrates machinery, hydraulic pressure, electrics, automation, and intelligent control, which can be used for medium crushing, fine cru...Get Quote

Hydraulic Cone CrusherHydraulic Cone Crusher integrates machinery, hydraulic pressure, electrics, automation, and intelligent control, which can be used for medium crushing, fine cru...Get Quote -

Impact CrusherImpact crusher is a type of machine designed to reduce large rocks, ores, and other hard materials into smaller, more manageable pieces. This equipment is widel...Get Quote

Impact CrusherImpact crusher is a type of machine designed to reduce large rocks, ores, and other hard materials into smaller, more manageable pieces. This equipment is widel...Get Quote -

Spring Cone CrusherSpring cone crushers are generally used in the medium and fine crushing links of mine crushing, and are mainly used in the secondary crushing and tertiary crush...Get Quote

Spring Cone CrusherSpring cone crushers are generally used in the medium and fine crushing links of mine crushing, and are mainly used in the secondary crushing and tertiary crush...Get Quote -

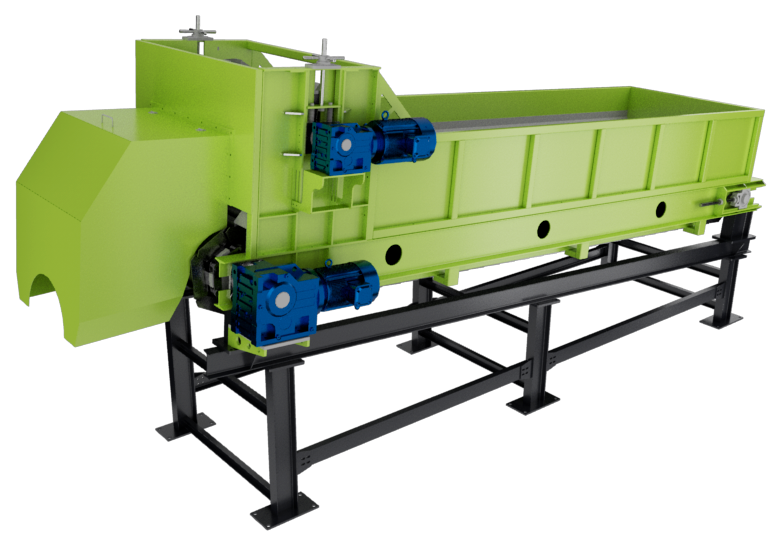

Bag OpenerBag opener or bag opener system is a mechanical device used to automatically open and empty bags containing bulk materials. This system is commonly used in indu...Get Quote

Bag OpenerBag opener or bag opener system is a mechanical device used to automatically open and empty bags containing bulk materials. This system is commonly used in indu...Get Quote