Municipal Solid Waste Recycling

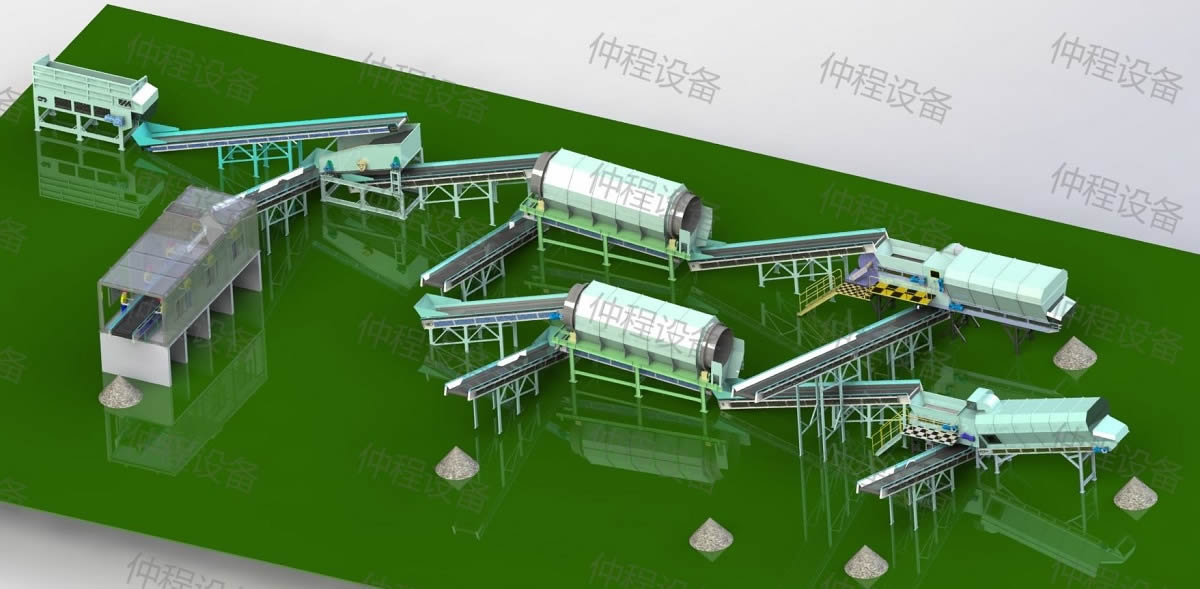

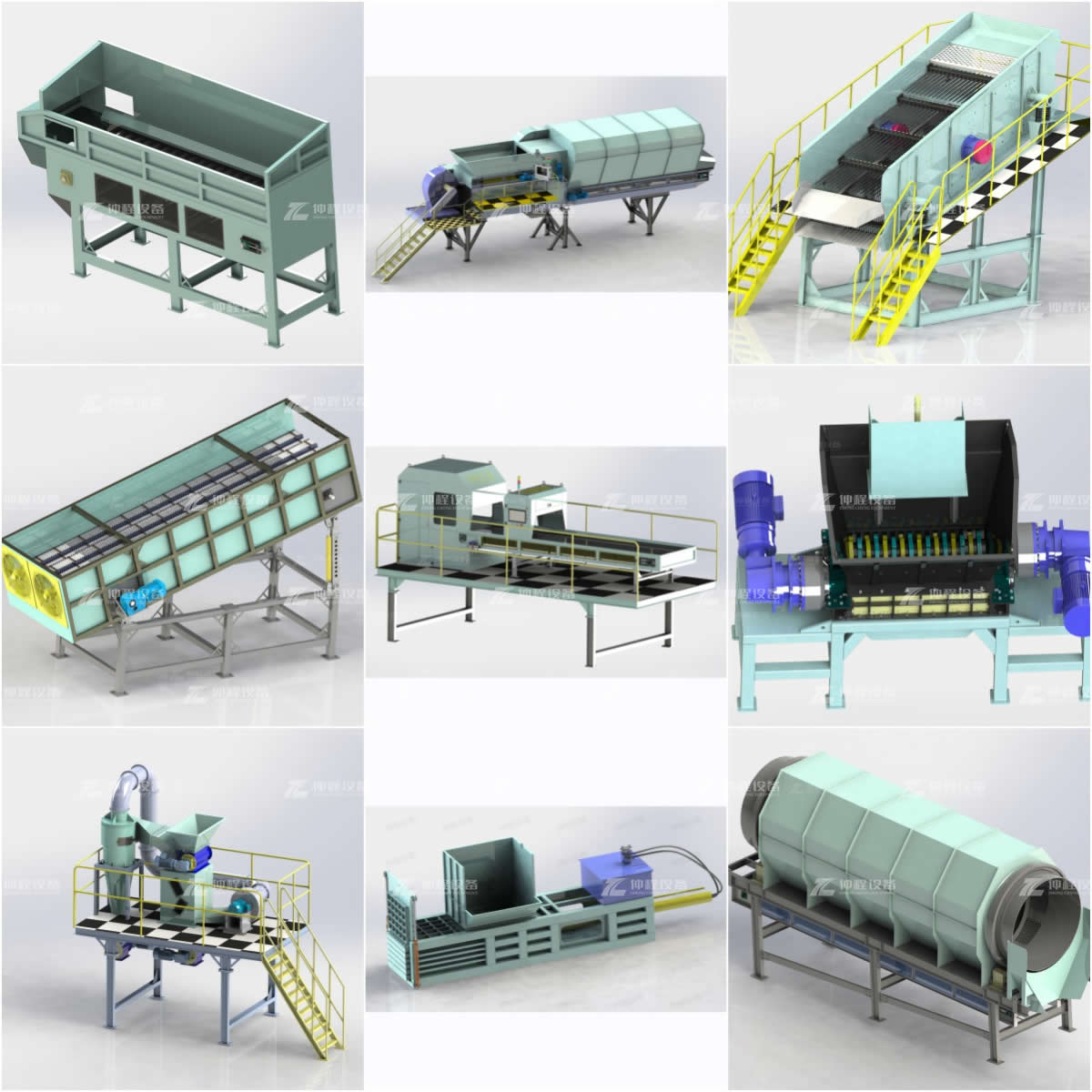

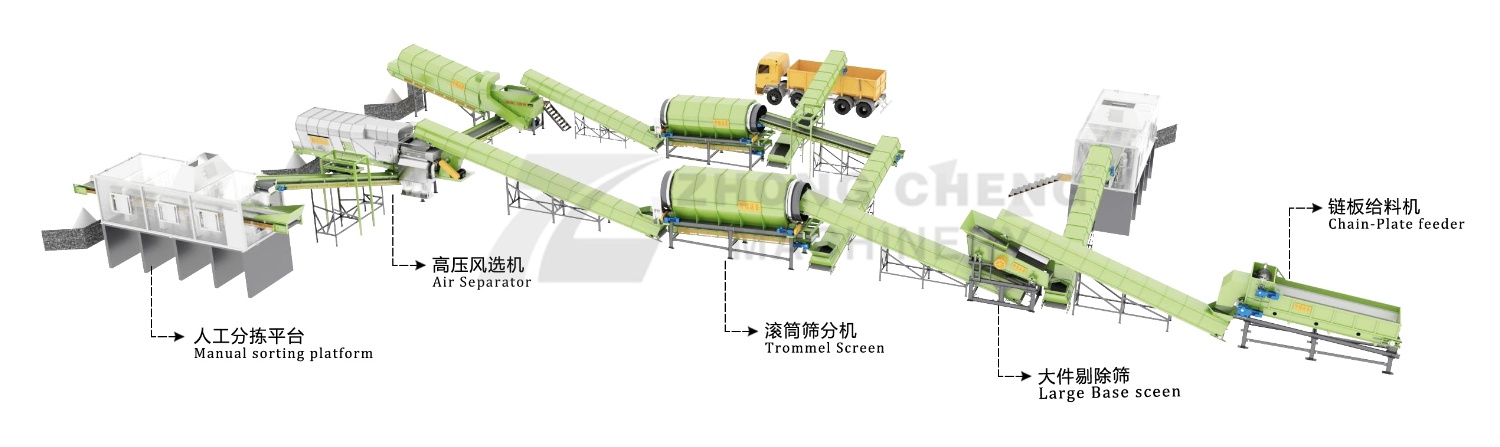

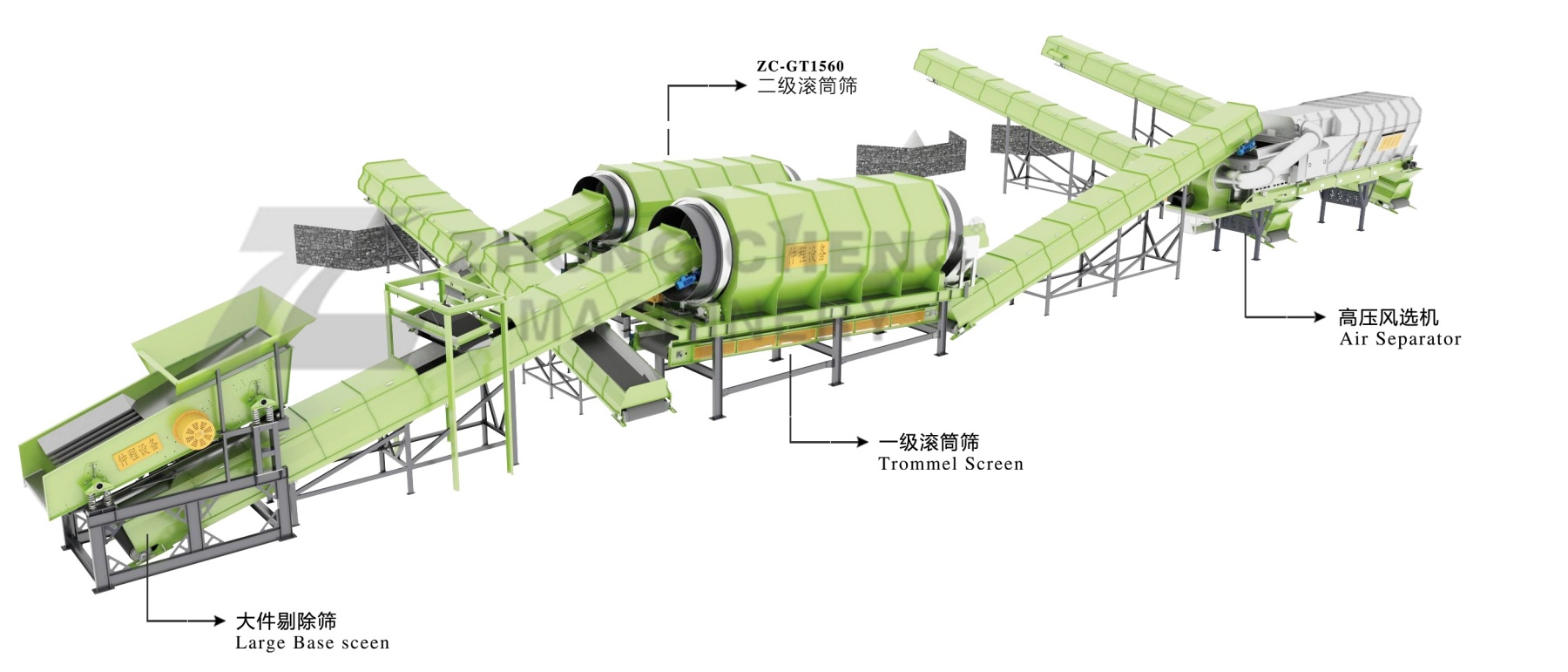

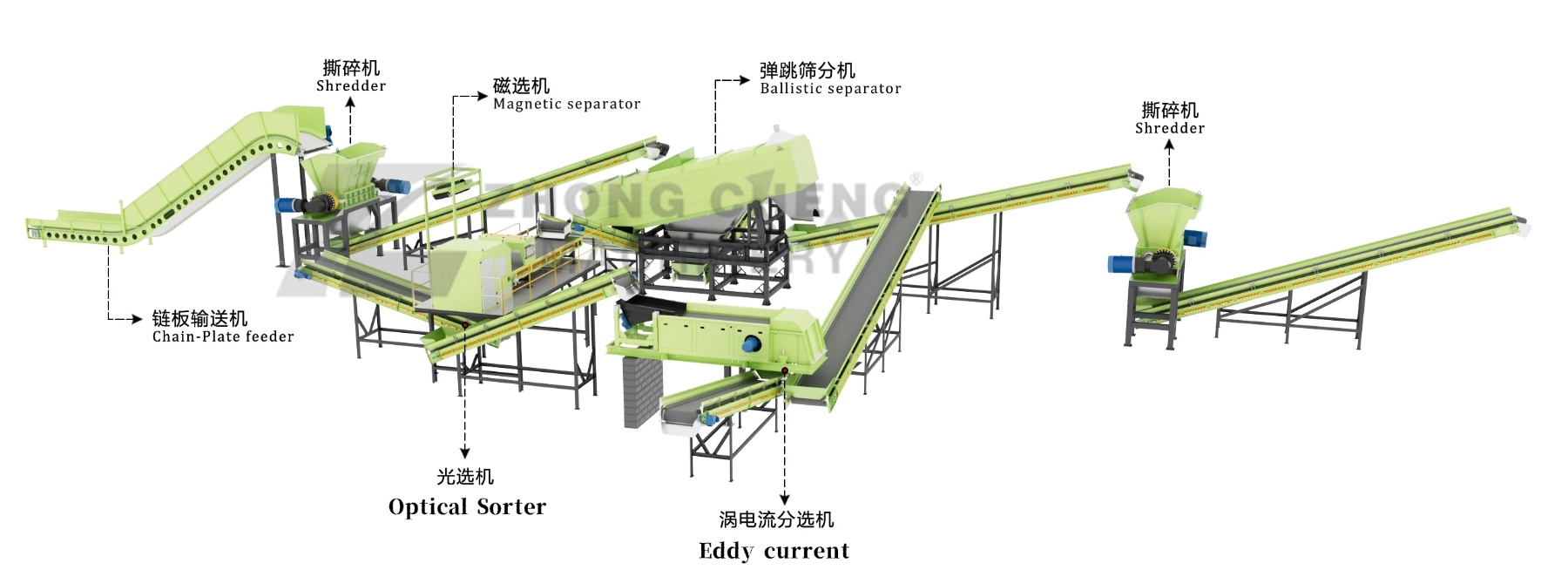

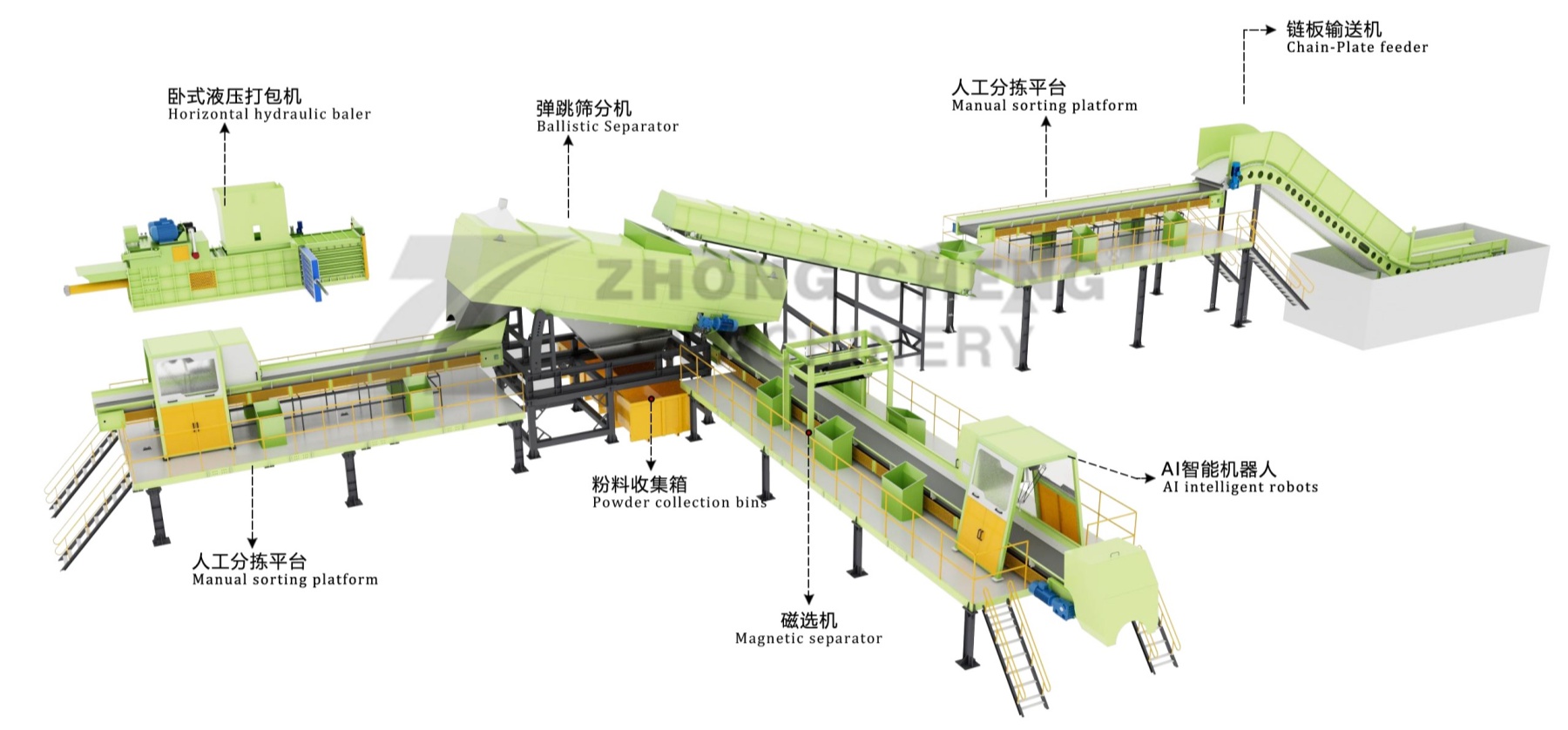

- Treatment process: Automatic optical sorters/ Magnetic separators /Eddy current separators /Screening technology /Conveyors /Apron feeders /Shredders /Balers

- Throughput: 5-35t/h

- Raw Material: Municipal Solid Waste

- Finished Material: Plastic,Metal,Brik and stone,Organic,Biomass

- Main Equipment: Apron Feeder,Trommel Screen,Ballistic Separator,Wind sifter,Hopper,Conveyor Systems,Sorting Robots,horizontal balers

- Case Description

Waste sorting machines, waste recycling plants, waste processing machines, waste processing plants, waste recycling machines

Municipal solid waste (MSW), also known as trash or garbage, is non-hazardous refuse generated by households, institutions, hospitals, and businesses,consists of everyday items like glass, plastics, metals, textiles, organics, and paper.

What is an MSW Sorting Machine?

An MSW sorting machine is a specialized facility designed to sort and segregate various components of municipal solid waste. These machines are engineered to handle a diverse array of materials, including organic waste, plastics, metals, glass, and paper. The primary goal is to separate recyclable and reusable materials from non-recyclable waste, thereby reducing landfill reliance and promoting recycling.

We offer different techniques and waste screening systems to separate material.

Municipal solid waste (MSW) is separated in different conveyors depending on their size and shapes by mechanical equipment before manual picking platforms.

In this way organics are separated before manual sorting to improve sorting quality. Ferrous and Non-Ferrous metals are sorted by machines automatically. Waste is separated by its shape as 2 dimensional and 3 dimensional. With this, sorting efficiency is increased with the same amount of manpower. Labor expenses decreased significantly. These plants generally includes equipment such as Feeding equipment, bag opener, trommel screen and/or finger screen, ballistic separator, magnetic separator, eddy current separator and baler press.

With this in hand, indifferent projects depending on needs, different designs are made for achieving maximum efficiency.

Key Components and Functions:

1.Chain Waste Conveyor: A Chain Waste Conveyor is a specialized type of conveyor system designed for transporting waste materials in various industrial and municipal settings. It’s an essential component in waste management and recycling facilities. The conveyor utilizes a chain-driven mechanism to move waste along a predetermined path, making it suitable for handling heavy loads and a variety of waste materials.

2.Bag breaker: A Bag Breaker is a machine designed for opening bags containing waste materials in recycling and waste processing facilities. Its primary function is to ensure that the contents of waste bags are exposed and available for subsequent sorting and processing. This equipment is crucial in facilities where waste arrives in bagged form, such as municipal solid waste (MSW) from residential or commercial sources.

3.Trommel Screen: A Trommel screen, also known as a rotary screen, is a mechanical screening machine used to separate materials, mainly in the mineral and solid-waste processing industries. It consists of a perforated cylindrical drum that is normally elevated at an angle at the feed end. The basic function of a Trommel screen is to screen out differing sizes of materials as they pass through a rotating screen.

4.Magnetic Separator:A Magnetic Separator is a device used in various industries, especially in recycling and mining, to remove magnetic materials from a flow of non-magnetic substances. This tool plays a pivotal role in the purification and sorting of materials, significantly contributing to resource recovery and recycling processes.

5.Eddy Current Separator: A Eddy Current Separator is a specialized tool used in the recycling industry to separate non-ferrous metals such as aluminum, copper, and brass from a waste stream. This type of magnetic separator is distinct for its ability to separate metals that do not have magnetic properties, making it a critical component in modern recycling facilities.

6.Vibrating Screen:A Vibrating Screen is a mechanical tool used extensively in the recycling, mining, and construction industries for separating and sorting various materials. Its primary function is to separate materials based on size using a mesh screen that vibrates. This simple yet effective mechanism makes the Vibrating Screen an indispensable part of many material processing lines.

7.Ballistic Separator: A Ballistic Separator is an advanced piece of equipment widely used in the recycling and waste management industry. Its primary function is to separate materials based on their density, shape, and size. This technology is especially effective for sorting mixed waste streams, such as Municipal Solid Waste (MSW), into distinct categories like paper, plastics, and other recyclables.

8.Air Separator: A Air Separator, also known as an air classifier or wind sifter, is a key component in the recycling and waste management industry. It is designed to separate light, voluminous materials from heavier items in a waste stream using air flow. This technology plays a crucial role in sorting and preparing waste for recycling, ensuring that valuable materials are recovered efficiently.

9.Manual Sorting Room: A Manual Sorting Room is a crucial component of many recycling and waste management facilities. While technology plays a significant role in sorting waste, the human element remains essential for achieving high levels of accuracy and efficiency in separating different types of materials. This article explores the importance, functions, and challenges of a Manual Sorting Room in the waste management process.

10.Optical Sorter: A Optical Sorter is a sophisticated machine widely used in recycling facilities to separate materials based on optical properties. This technology is particularly effective in sorting waste streams that contain a mix of materials, including plastics, paper, glass, and metals. Utilizing advanced sensors and high-speed data processing, Optical Sorters significantly enhance the efficiency and accuracy of recycling operations.

11.Waste Baler: A Waste Baler is a machine commonly used in waste management and recycling facilities to compress waste materials into compact, manageable bales. This process not only reduces the volume of waste but also facilitates easier handling, transportation, and storage. Waste Balers are essential in the modern approach to waste management, especially in recycling and sustainability efforts.

Waste sorting machines, waste recycling plants, waste processing machines, waste processing plants, waste recycling machines