Drum Screen Recycling

-

Production Capacity:

30~200m³/h

-

Applicable Industries:

Recycling Plants/Waste Management/Composting Facilities/MSW

-

Power:

5.5-22kw

-

Core Components:

CE / ISO:9001

-

Place of Origin:

Henan, China

- Product Details

- Characteristics

- Working Principle and Application

- Parameters

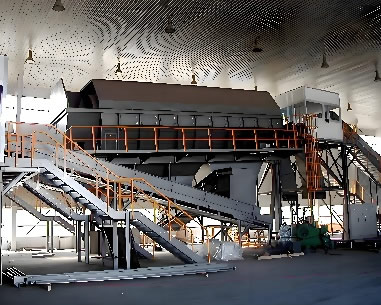

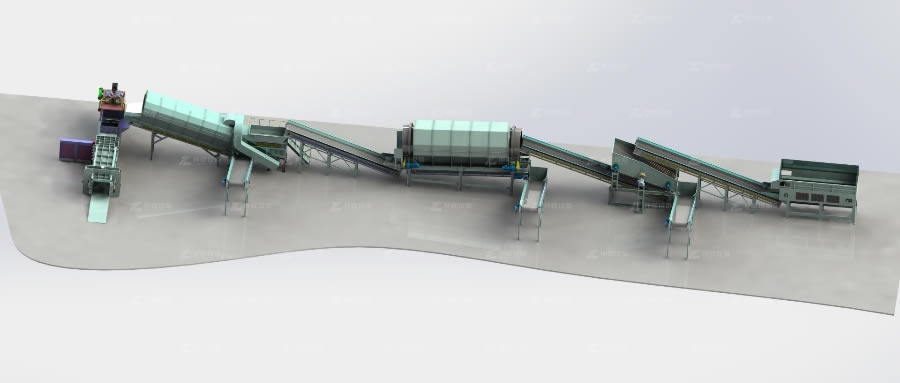

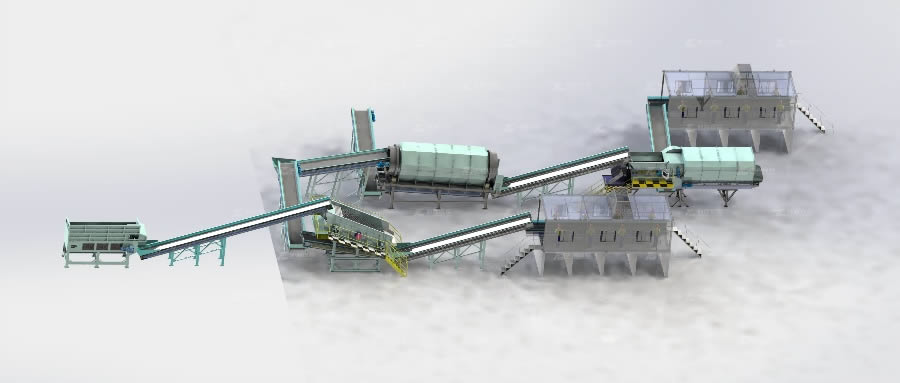

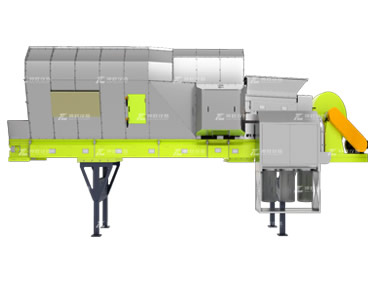

High-Performance Drum Screening Machines for Municipal Solid Waste Recycling

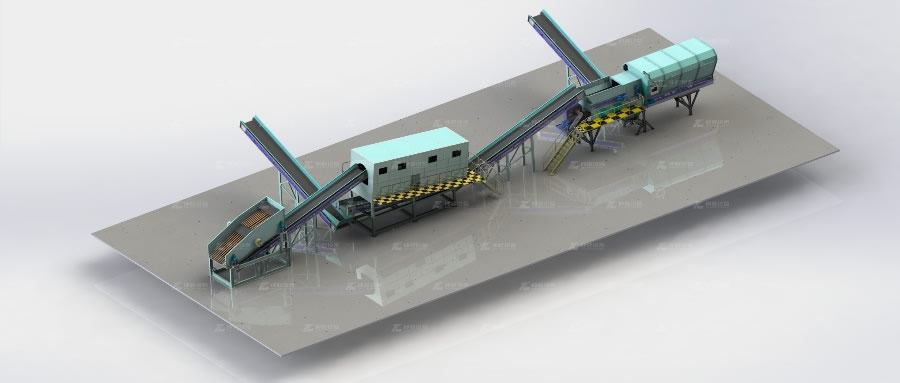

Drum screening machines, also known as trommel screens or rotary screens, play a vital role in the recycling industry. These machines are primarily used for material screening, helping to sort and recycle municipal solid waste and screen landfill waste. Their efficiency and reliability make them indispensable in waste management operations.

Key Features of Drum Screening Machines

Advanced Screening Technology

Drum screening machines utilize advanced technology to ensure precise separation of materials. The rotary motion and angled drum facilitate effective sorting, allowing for the efficient processing of large volumes of waste. This technology ensures minimal downtime and maximum productivity.

Durable and Robust Design

Built to withstand the rigors of industrial use, drum screening machines feature a robust design. High-quality materials and superior craftsmanship ensure longevity and reliable performance, even in the harshest environments. This durability translates to lower maintenance costs and higher return on investment.

Versatile Applications

Drum screening machines are incredibly versatile. They are suitable for a variety of applications, including the sorting and recycling of municipal solid waste, compost, and construction debris. Their adaptability makes them a valuable asset across different sectors within the recycling industry.

Benefits of Using Drum Screening Machines

Enhanced Efficiency

One of the primary benefits of drum screening machines is their ability to enhance efficiency in waste processing. By automating the screening process, these machines reduce manual labor, increase throughput, and improve the overall speed of waste management operations.

Cost-Effective Solution

Investing in drum screening machines is a cost-effective solution for waste management facilities. The automation and efficiency they provide lead to significant cost savings in terms of labor, time, and operational expenses. Additionally, their durability reduces the need for frequent replacements.

Environmental Impact

Using drum screening machines contributes to environmental sustainability. By efficiently sorting and recycling waste, these machines help reduce landfill use and promote the reuse of materials. This not only conserves resources but also minimizes the environmental footprint of waste management operations.

-

01High Screening Efficiency: Precise separation of materials ensures optimal recycling processes. Robust Construction: Designed for heavy-duty operations, ensuring durability and long-term use.

-

02Customizable Options: Tailored solutions to meet specific recycling needs and requirements.

-

03Eco-Friendly: Supports sustainable waste management practices by improving material recovery. Low Maintenance: Engineered for easy maintenance, reducing downtime and operational costs.

-

04Versatile Applications: Suitable for various types of waste, including municipal and landfill waste.

How to Choose the Right Drum Screening Machine

Assessing Your Needs

Start by assessing your specific needs. Consider the volume of waste you need to process, the type of materials, and the desired output. Understanding these requirements will help you choose a machine that fits your operations perfectly.

Comparing Models

Compare different models based on their features, performance, and cost. Look for reviews and testimonials from other users to gauge the reliability and efficiency of each model. This comparison will help you make an informed decision.

Considering Future Scalability

Think about future scalability when selecting a drum screening machine. Choose a model that can handle potential increases in waste volume and adapt to evolving waste management needs. Investing in a scalable machine ensures long-term value.

Best Practices for Operating Drum Screening Machines

Regular Maintenance

To keep your drum screening machine in optimal condition, implement a regular maintenance schedule. Routine checks and servicing can prevent unexpected breakdowns and extend the lifespan of the machine. This practice ensures consistent performance and reduces long-term repair costs.

Operator Training

Ensure that all operators are well-trained in using the drum screening machine. Proper training enhances safety and efficiency, minimizing the risk of operational errors. Well-trained staff can also identify potential issues early, preventing costly downtime.

Monitoring Performance

Regularly monitor the performance of your drum screening machine. Keep track of metrics such as throughput, efficiency, and downtime. Analyzing this data helps in identifying areas for improvement and optimizing the overall operation.

Innovations in Drum Screening Machine Technology

Automated Controls

Modern drum screening machines often come equipped with automated controls. These systems allow for precise adjustments and real-time monitoring, enhancing the efficiency and accuracy of the screening process. Automation reduces the need for manual intervention, increasing overall productivity.

Energy-Efficient Designs

Recent innovations have led to more energy-efficient drum screening machines. These designs reduce power consumption without compromising performance. Investing in energy-efficient equipment can lead to significant cost savings and contribute to sustainability goals.

Modular Components

The use of modular components in drum screening machines allows for easier upgrades and maintenance. Modular designs enable quick replacements of parts, minimizing downtime and ensuring the machine operates at peak efficiency. This flexibility is particularly beneficial for adapting to changing waste processing needs.

Case Studies: Success Stories in Using Drum Screening Machines

Municipal Waste Management Facility

A municipal waste management facility implemented drum screening machines to enhance their waste processing capabilities. The machines significantly increased the efficiency of sorting and recycling operations, leading to a 30% reduction in landfill waste. The facility also reported substantial cost savings due to reduced labor and operational expenses.

Construction and Demolition Recycling Center

A construction and demolition recycling center integrated drum screening machines into their processing line. The machines effectively separated recyclable materials from debris, improving the quality of recycled products. The center saw a marked increase in throughput and a reduction in processing time, boosting overall productivity.

| Model | Length Range | Segment No. | Aperture Size | Power (Kw) | Inclined Angle | Max. Material Size | Rotating Speed(rpm) |

| ZCφ600 | 2-4m | 1-2 | ≤30mm | 2.2-3 | 0-7° | 60mm | 12-18 |

| ZCφ800 | 2-5m | 1-3 | ≤50mm | 3-5.5 | 0-7° | 100mm | 12-18 |

| ZCφ1000 | 2-6m | 1-4 | ≤100mm | 4-11 | 0-7° | 150mm | 10-18 |

| ZCφ1200 | 3-8m | 1-4 | ≤150mm | 5.5-18.5 | 0-7° | 200mm | 9-15 |

| ZCφ1500 | 3-10m | 1-5 | ≤200mm | 7.5-22 | 0-7° | 250mm | 9-15 |

| ZCφ1800 | 4-12m | 1-5 | ≤220mm | 7.5-22 | 0-7° | 270mm | 8-15 |

| ZCφ2000 | 5-15m | 1-5 | ≤250mm | 11-30 | 0-7° | 300mm | 8-12 |

| ZCφ2500 | 5-18m | 1-6 | ≤300mm | 11-30 | 0-7° | 350mm | 8-12 |

customized according to your requirements

-

Mini Copper Wire GranulatorThe copper wire granulator machine is a device specially used to process waste wires and cables. Its main function is to separate the copper and plastic in the ...Get Quote

Mini Copper Wire GranulatorThe copper wire granulator machine is a device specially used to process waste wires and cables. Its main function is to separate the copper and plastic in the ...Get Quote -

Recycling Finger ScreensFinger screen is a type of screening equipment used to separate materials based on size. Unlike traditional screens, finger screens consist of a series of paral...Get Quote

Recycling Finger ScreensFinger screen is a type of screening equipment used to separate materials based on size. Unlike traditional screens, finger screens consist of a series of paral...Get Quote -

Drum Screen RecyclingDrum screen machines are primarily used for material screening, helping to sort and recycle municipal solid waste and screen landfill waste. Their efficiency an...Get Quote

Drum Screen RecyclingDrum screen machines are primarily used for material screening, helping to sort and recycle municipal solid waste and screen landfill waste. Their efficiency an...Get Quote -

WindshifterWindshifter (Air Drum Separator ) is the ideal solution for separating all kind of waste types into two fractions, heavy and light. The robust construction and ...Get Quote

WindshifterWindshifter (Air Drum Separator ) is the ideal solution for separating all kind of waste types into two fractions, heavy and light. The robust construction and ...Get Quote