Windshifter

-

Production Capacity:

30~260m³/h

-

Applicable Industries:

C&D, C&I, WEEE, MBT, RDF/SRF, MSW, ASR and many more

-

Power:

18.5-55kw

-

Core Components:

semi-mobile and stationary, with an integrated dust filtration system, an electrical cabinet, support and for abrasive materials with a wear resistant configuration.

-

Place of Origin:

Henan, China

- Product Details

- Characteristics

- Working Principle and Application

- Parameters

Maximize Waste Sorting Efficiency with Our Advanced Windsifter

Welcome to zhongcheng company, your trusted partner in waste sorting solutions. Our windsifter is engineered with precision and innovation to deliver unparalleled efficiency and reliability. Designed to optimize your waste management processes, our air drum separator is the ultimate choice for enhancing your operations. Discover the benefits of advanced separation technology and see how we can elevate your waste sorting capabilities.

Windsifter, also known as an air classifier or air drum separator, is a machine used to separate materials based on their aerodynamic properties, such as density and size. Wind sifters are commonly used in recycling, waste management, and various industrial processes. They can handle a wide range of materials, including municipal solid waste, construction and demolition debris, compost, and various industrial waste.

Application Areas of The windsifter (Air Drum Separator) :

Recycling Plants: Enhance the efficiency of your recycling process by accurately sorting different materials, leading to higher purity in recycled outputs.

Waste Management Facilities: Improve the overall effectiveness of your waste sorting operations, reducing manual labor and increasing throughput.

Construction and Demolition Sites: Separate construction debris efficiently, enabling the recovery of valuable materials and reducing disposal costs.

Agricultural Waste Processing: Optimize the separation of organic and inorganic materials, facilitating better waste management in agricultural settings.

Customer Testimonials:

John D., Waste Management Facility Owner: “Our facility’s efficiency has significantly increased since we integrated Zhongcheng’s windsifter. The reliability and ease of maintenance have made a huge difference in our operations.”

Sarah K., Recycling Plant Manager: “The customizable settings allowed us to fine-tune the separation process to our specific needs. It’s a game-changer for our recycling efforts, and we highly recommend it.”

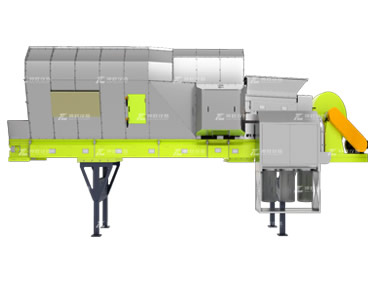

Windsifter Material Recovery Solution ,Windshifter,Air Sifter For Your Recycling Materials,Single Drum Air Density Separator

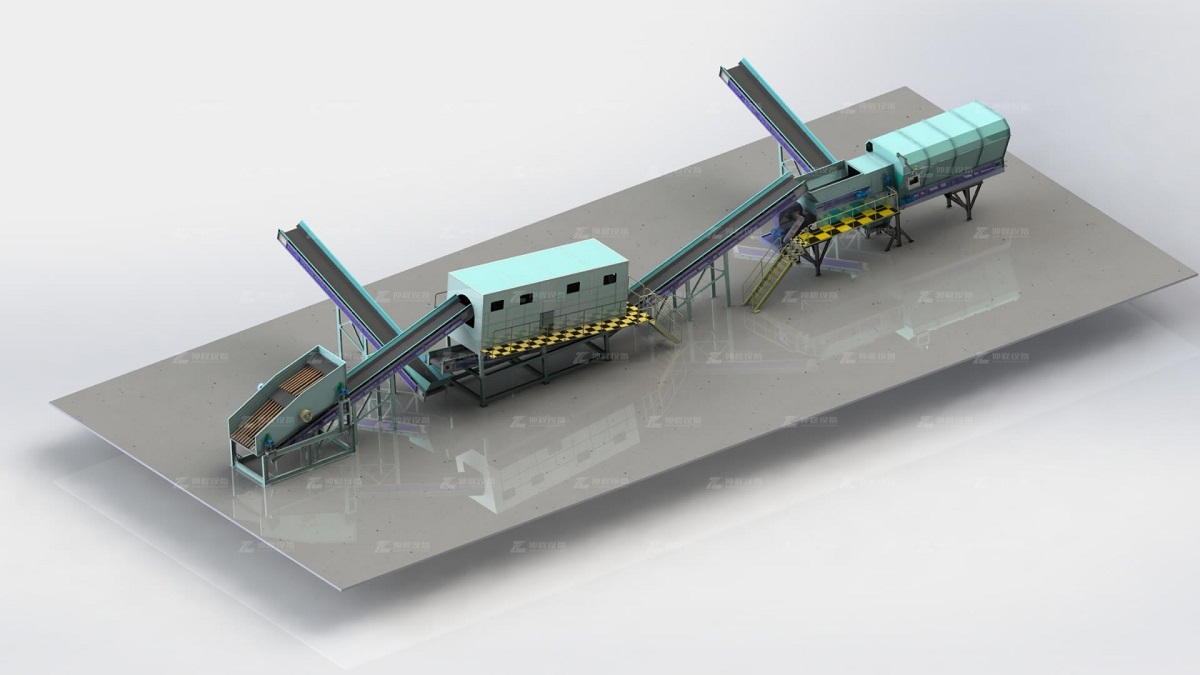

The windsifter (Air Drum Separator) uses industry-leading negative pressure technology to sort a wide range of materials by density. It is suitable for virtually all kinds of solid waste up to 200 mm, including Commercial and Industrial (C&I) waste, Construction and Demolition (C&D) waste, Municipal Solid Waste (MSW), Refuse Derived Fuel (RDF), Automotive Shredder Residue (ASR), compost, and more.

-

01Separating bulky waste effectively . (eg bulky plastic film).Equipped with stone catcher to prevent blockage inside the blow ducting

-

02Using industry-leading negative pressure technology to remove inert from the waste stream .

-

03Low maintenance and very few wearable parts, thus reduced downtime, low operational costs。Low energy consumption due to our unique configuration with a recirculation fan。

-

04Can handle a wide range of materials, including municipal solid waste, construction and demolition debris, compost, and various industrial wastes. This versatility makes them valuable across multiple sectors.

The windsifter (Air Drum Separator) use a combination of airflow and mechanical action to separate materials:

Feed Material: Mixed material is fed into the separator.

Airflow: An airstream is introduced, lifting and separating lighter materials from heavier ones.

Drum Action: The rotating drum further aids in the separation by carrying lighter materials upwards while heavier materials fall.

Collection: Separated materials are collected in different chambers or on conveyor belts for further processing or disposal.

The patented windshifter stands out by effectively separating heavy and light fractions using three main components: the acceleration belt, the air jet, and the separation drum.

For optimal results, the accelerator belt ensures a single-layer distribution of the input material, which is critical for even spreading across the width of the windshifter. The material is accelerated to an adapted speed and transported to the ejection edge. As the material falls, it enters an upward current generated by an adjustable air jet beneath the feeding belt.

Additionally, the airstream meets the upper area of the rotating drum and is fed through it into the expansion chamber with laminar flow. The material meets the airflow and is separated into light and heavy fractions.

Light materials are carried at high speed into the expansion chamber, where the air speed is reduced, allowing the light materials to reach a container or discharge belt. Heavy materials fall from the rotating drum into a container or onto a discharge belt.

The two-way fraction is created with an air separation point and a splitter drum, at which the heavy material is separated from the light material.

The separation of the input material can be adjusted by controlling the fan speed and the adjustments of the dampers that affect the direction, flow and speed of the air.

Windsifter Material Recovery Solution ,Windshifter,Air Sifter For Your Recycling Materials,Single Drum Air Density Separator

| Wind Sifter800 | Wind Sifter1200 | Wind Sifter1600 | |

| Feeding Belt Width | 800mm | 1200mm | 1600mm |

| Air volume | 8000-19000 m³/h | 12000-29000 m³/h | 15000-35000 m³/h |

| Full pressure | 2500Pa | 2500Pa | 2500Pa |

| Power | 38kw | 42kw | 55kw |

| Throughput | 20-30 m³/h | 30-50 m³/h | 50-70 m³/h |

-

WindshifterWindshifter (Air Drum Separator ) is the ideal solution for separating all kind of waste types into two fractions, heavy and light. The robust construction and ...Get Quote

WindshifterWindshifter (Air Drum Separator ) is the ideal solution for separating all kind of waste types into two fractions, heavy and light. The robust construction and ...Get Quote -

Disc ScreenDisc screen, also known as a disc scalping screen, is a mechanical device used to separate materials based on size. It is commonly used in industries such as wa...Get Quote

Disc ScreenDisc screen, also known as a disc scalping screen, is a mechanical device used to separate materials based on size. It is commonly used in industries such as wa...Get Quote -

Ballistic SeparatorBallistic separators are a crucial component in modern recycling and waste management systems, contributing to more efficient resource recovery and environmenta...Get Quote

Ballistic SeparatorBallistic separators are a crucial component in modern recycling and waste management systems, contributing to more efficient resource recovery and environmenta...Get Quote -

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote