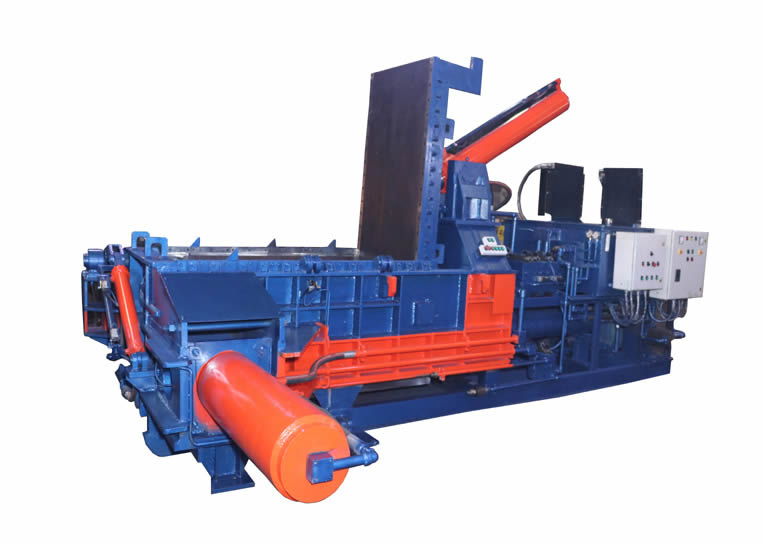

Horizontal Semi-Auto Hydraulic Baler

-

Production Capacity:

6-10T/H

-

Applicable Industries:

Paper/Carton Box/plastic/PET Bottles/Drinks Cans/ MSW, etc.

-

Power:

15kw-55kw

-

Core Components:

Sieve plate、PLC

-

Place of Origin:

Henan, China

- Product Details

- Characteristics

- Working Principle and Application

- Parameters

Horizontal Semi-Automatic Hydraulic Baler

Scope of application:

Widely used in paper mills, printing plants, packaging plants, garbage sorting and recycling stations, recycling stations, and other places;

It is suitable for recycling, compression, and packaging of loose materials such as waste paper, waste cardboard, paper mill waste paper scraps, waste books, plastic films, cloth, fibers, and straw. It can be used in conjunction with conveyors or air ducts.

Performance features:

●Closed structure makes the block compression stronger.

●PLC program control, electric button operation, built-in feeding detection, safe and convenient operation.

●High-strength bag exit door, automatic door opening, and closing, hydraulic door locking, making operation more convenient.

●Reasonable double-scissor blade design improves paper-cutting efficiency and extends blade service life.

●The main oil cylinder adopts a lug bracket and ball end face design, which can eliminate the torque acting on the main shaft and significantly extend the life of the oil seal.

●No special site infrastructure is required, making installation simple and easy.

Bale tying is quick, easy and safe and with the slotted end door, there is no setting up of wires. The model baler is suitable for fitting out with a range of loading options to suit each client’s individual needs.

-

01Increased Throughput

-

02Space Optimization

-

03Cost-Effective Automation

-

04Reduced Labor Requirements

Baler is a high quality, continuous feed, fully automatic baler with a large feed aperture and high press force that, depending on motor/power choice and materials, will process typically 12-25 tph of cardboard, paper, polythene film, hard plastics, PET bottles, drinks cans, MSW/RDF/SRF, etc.

Cardboard and Paper Recycling

Perfect for compressing corrugated cartons, newsprint, and office paper, this baler helps significantly

reduce the storage space needed and lowers the frequency of waste collection services.

Plastic Film and PET Bottles

From stretch film and shrink wrap to PET bottle baling, the semi-auto horizontal baler can handle a wide

range of plastic types. The resulting bales are highly compact and optimized for transport or further

processing.

Textile and Fabric Waste

Garment manufacturers and textile recyclers benefit from the baler's ability to manage scrap cloth,

cotton, wool, and synthetic fibers with high efficiency, streamlining waste handling processes.

Aluminum and Metal Cans

Light metals such as beverage cans and aluminum foil are easily compressed, facilitating storage and resale

while complying with environmental regulations.

| ZC130 | ZC160 | ZC180 | ZC200 | ZC250 | |

| Feeding hopper size | 2050x1150mm | 2050x1150mm | 2050x1150mm | 2050x1150mm | 2050x1150mm |

| Working pressure | 25 Mpa | 25 Mpa | 25 Mpa | 25 Mpa | 25 Mpa |

| Wire quantity | 7 | 7 | 7 | 7 | 7 |

| Bale weight | 1000-1100kg | 1200-1300kg | 1300-1600kg | 1600-1800kg | 1600-1800kg |

| Bale size 1 | 700x1150x1250mm | 1700x1150x1250mm | 1700x1150x1250mm | 1700x1150x1250mm | 1700x1150x1250mm |

| Capacity | 5000-6000kg/h | 6000-7000kg/h | 7000-8500kg/h | 8000-9000kg/h | 8000-9000kg/h |

| Oil tank | 1200L | 1400L | 1500L | 1500L | 1500L |

| Working power | 37KW | 45KW | 52KW | 52KW | 60KW |

| Feeding Conveyor | Feeding Conveyor | Feeding Conveyor | Feeding Conveyor | Feeding Conveyor | Feeding Conveyor |

| Width | 1500mm | 1500mm | 1500mm | 1500mm | 1500mm |

| Power | 5.5KW | 5.5KW | 5.5KW | 5.5KW | 5.5KW |

| Cooling Tower | Cooling Tower | Cooling Tower | Cooling Tower | Cooling Tower | Cooling Tower |

| Power | 0.25KW | 0.25KW | 0.25KW | 0.25KW | 0.25KW |

-

Metal BalerMetal baler, specifically a hydraulic metal baler, is a machine designed to compress scrap metal into dense, manageable bales. This equipment is widely used in ...Get Quote

Metal BalerMetal baler, specifically a hydraulic metal baler, is a machine designed to compress scrap metal into dense, manageable bales. This equipment is widely used in ...Get Quote -

Waste Baler For MSWHigh density solid waste balers are the final step before sending waste to landfill. Horizontal balers designed and manufactured for this difficult job and prov...Get Quote

Waste Baler For MSWHigh density solid waste balers are the final step before sending waste to landfill. Horizontal balers designed and manufactured for this difficult job and prov...Get Quote -

RDF Making MachineRDF (Refuse Derived Fuel) making machine is a specialized equipment used in waste management and energy recovery processes. Its primary function is to convert v...Get Quote

RDF Making MachineRDF (Refuse Derived Fuel) making machine is a specialized equipment used in waste management and energy recovery processes. Its primary function is to convert v...Get Quote -

Horizontal Semi-Auto Hydraulic BalerSemi automatic balers are used across the logistics, recycling and manufacturing sectors to process large volumes of waste materials such as cardboard, film, pa...Get Quote

Horizontal Semi-Auto Hydraulic BalerSemi automatic balers are used across the logistics, recycling and manufacturing sectors to process large volumes of waste materials such as cardboard, film, pa...Get Quote