Tire Recycling Plant

- Treatment process:

- Throughput:

- Raw Material:

- Finished Material:

- Main Equipment:

- Case Description

Tire Recycling Plant

Exploit the potential of waste tires!With our tire recycling plants for industries, we enable you to separate your tires almost 100% into their main components textile, rubber granulates and steel.Zhong Cheng Recycling plants recover the raw materials in a multi-stage recycling process that achieves highest levels of purity.

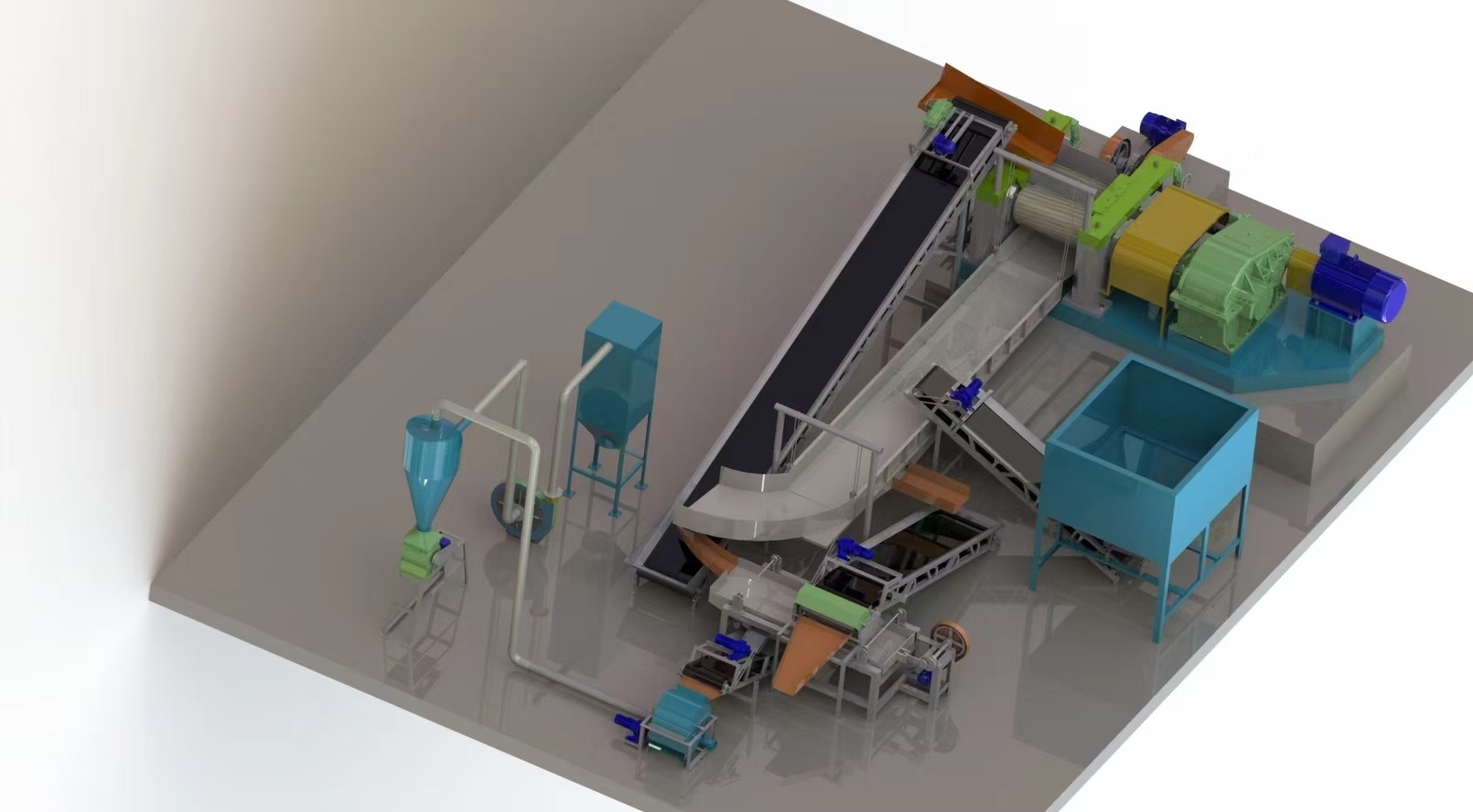

Wast Tire Recycling Systems

There are many ways to recycle tires, among which mechanical recycling is currently the most widely used method. Through processes such as crushing, grinding and screening, waste tires are broken down into rubber powder, steel wire and fiber. We can provide professional soulutions and full set tire recycling machines including tire shredder, tire wire drawing machine, tire ring cutter, rubber mill, magnetic separator, etc. for tire recycling plant.The overall design of Fully-Automatic Tyre Recycling Line is reasonable, high degree of automation, easy to use and maintain, and no need to add any other chemicals, no pollution to the environment. This is the best way to recycling scrap tires. You can implement integration solution for the customer.

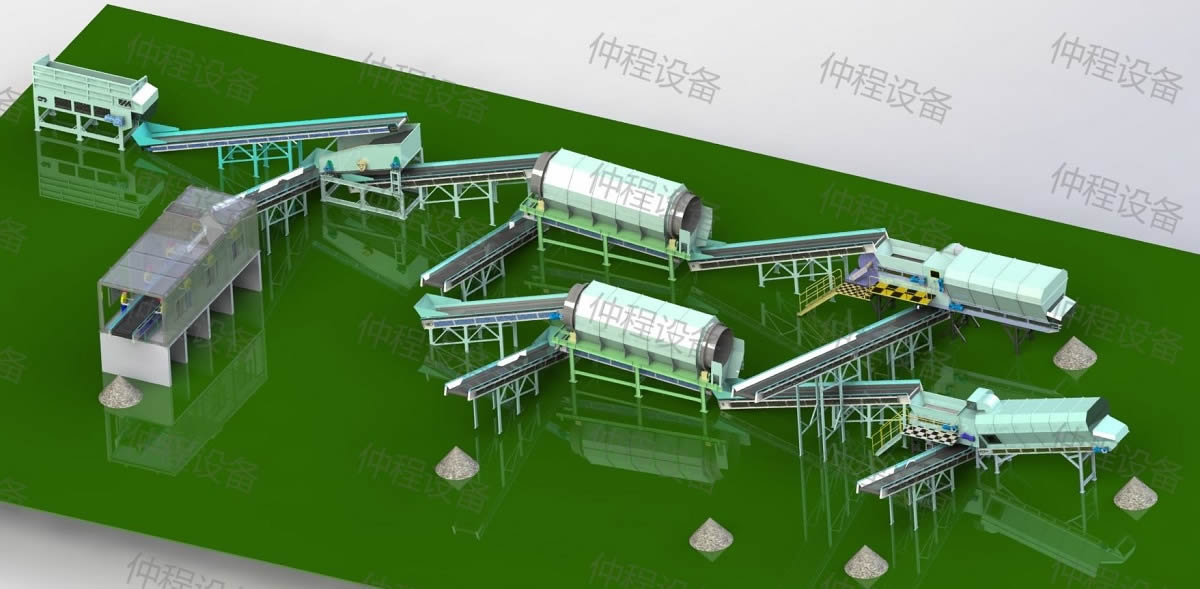

FLOOR PLAN OF TIRE RECYCLING PRODUCTION LINE

Work procedure

1.Automatic tire breaker →Cut and crush the tire into 5-10 cm rubber blocks

2.storage silo→Storage rubber block

3.roller crusher→Using the principle of two-roll relative operation extrusion grinding, the 5-10 cm block is crushed and ground into particles

4.4000 type conveyo→Transfer the glue blocks stored in the silo to the large shaker

5.Model 8000 main vibrating screen→The steel wire rubber material crushed by the main machine crusher is screened

6.9000 type conveyor→The rubber that does not meet the screening requirements is re-sent to the main machine crusher by the conveyor for re-crushing

7.3000 type conveyor→The main vibrating screen discharge is delivered by the conveyor to the first magnetic separator

8.magnetic separator→The main vibrating screen reaches the specification of the material by the magnetic separator will be rubber and steel wire separation

9.Model 4000 screening machine→The material that meets the specification is screened out of the finished product by the vibrating screen, and the material that does not meet the standard is circulated to the large conveyor into the main machine

10.magnetic separator→The finished material goes through the magnetic separator for a second magnetic separation

11.Cyclone dust bag filling machine→Collect finished materials by air cleaning and bagging

12.distribution cabinet

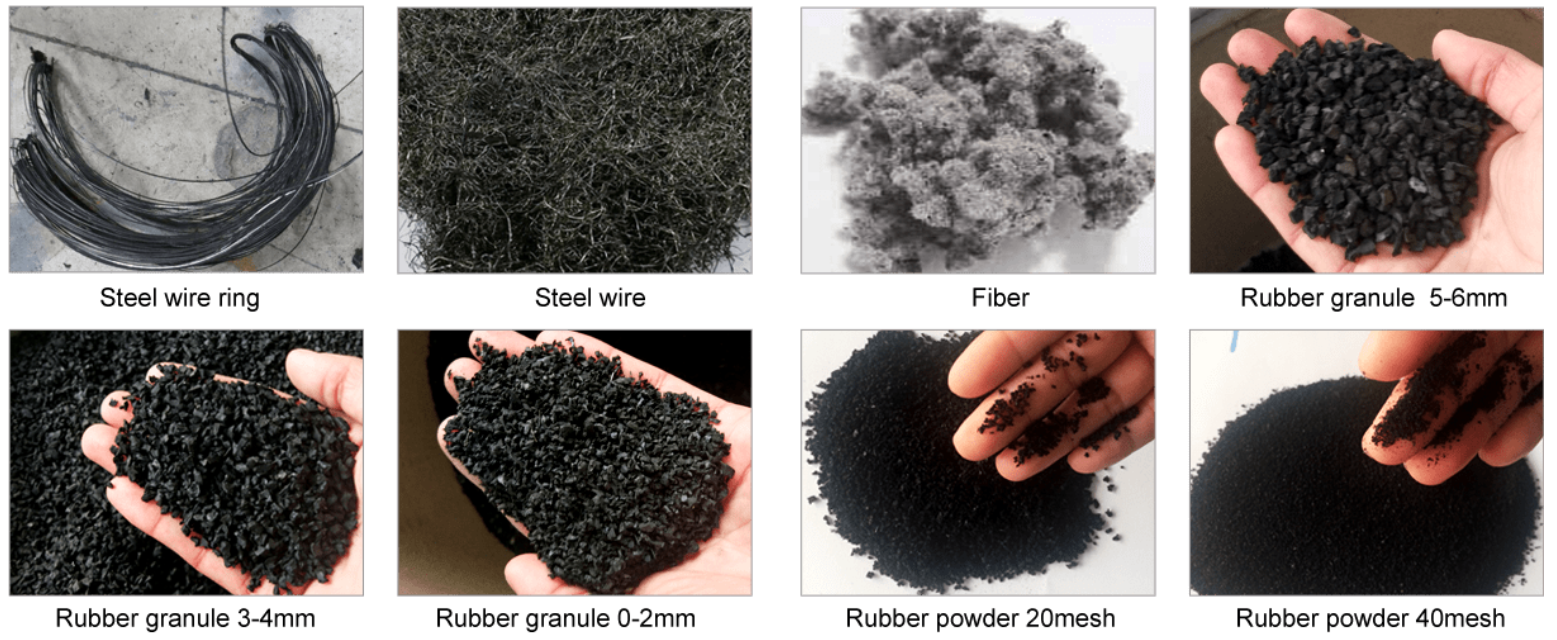

By Tire recycling plant, get the final product is rubber powder, fiber and steel wire, concrete rubber powder fineness (mesh) can be processed according to the needs of customers. We can offer different capacity of waste tire recycling plant from 100 kg/h to 3000 kg/h. The rubber powder size 10, 20 mesh, 30 mesh, 40 mesh, 60 mesh, 80 mesh, and the Max 120 mesh.

Main Equipments

Tire Shredder - Effortlessly Handling Old Tires

Our tire shredder is your solution for efficient and eco-friendly waste tire recycling. This cutting-edge machine is engineered to transform discarded tires into valuable resources, contributing to a cleaner environment and sustainable business practices.With its powerful motor and robust construction, our Tire Shredder can process a wide range of tire sizes, from passenger car tires to heavy-duty truck tires. It shreds them into uniform, manageable pieces, making the recycled rubber ideal for various applications, including asphalt, playground surfaces, and more.The Tire Shredder not only reduces waste but also provides an eco-conscious and profitable recycling solution. Its user-friendly operation and low maintenance requirements make it a practical choice for businesses looking to enhance their tire recycling capabilities.

| Parameter/model | ZPS-900 | ZPS-1200 |

| Adopt tire | φ900mm | φ1200mm |

| Output block size(size) | 50*50 | 50*50 |

| Power | 22*2 | 55*2 |

| Capacity | 22*2 | 55*2 |

| Size(mm) | 3800*2030*3300 | 4100*2730*3300 |

| Weight(T) | 6000 | 16000 |

Rubber Cracker - Transforming Waste into Value

Our rubber crusher is designed to further crush rubber blocks after coarse shredding, separating steel wire from the rubber. It efficiently produces rubber granules or powder, ideal for rubber recycling. This machine is specifically built for steel wire tire rubber powder processing.With powerful transmission, high efficiency, and low noise, it offers long-lasting performance. The well-designed structure ensures stable operation and exceptional quality. Easy to operate and environmentally friendly, this machine is the perfect solution for recycling and producing eco-friendly materials.

| Parameter/model | XKP-400 | XKP-450 | XKP-560 | XKP-610 |

Front Roll diameter (mm) | 400 | 450 | 560 | 610 |

| Back Roll diameter (mm) | 400 | 450 | 510 | 610 |

| Roll working length(mm) | 600 | 800 | 800 | 1000 |

Roll ratio | 1:1.237 | 1:1.38 | 1:1.3 | 1:1.3 |

Front roll speed(m/min | 17.32 | 23.2 | 25.6 | 28.4 |

| Adjusting nip range (mm) | 0-10 | 0-10 | 0-15 | 0-15 |

Motor power(kw) | 37 | 55 | 110 | 160 |

| Overall dimensions(mm) | 3950*1800*1780 | 1770*1846*1835 | 4750*2300*2000 | 7240*3800*1800 |

| Weight(t) | 8 | 12 | 20 | 25 |

Fiber Separator - Redefining Recycling Efficiency

Our Fiber Separator represents the pinnacle of recycling technology. It plays a pivotal role in transforming waste materials into valuable resources, particularly in industries dealing with rubber, plastics, and other mixed materials.Designed with precision and ingenuity, this advanced separator ensures that fibers are efficiently separated from the input material, allowing for a higher degree of recycling and reusability. This not only reduces waste but also conserves valuable resources, making it an eco-conscious choice for businesses.The Fiber Separator stands as a testament to our commitment to sustainable and eco-friendly practices. By incorporating this technology into your recycling process, you are contributing to a cleaner and greener future. With its user-friendly design and robust performance, it’s a powerful tool to maximize material recycling efficiency. Choose the Fiber Separator and embrace a more sustainable approach to recycling.

| Paramenter/model | FS-110 |

| Power(kw) | 11 |

| Capacity(kg) | 500-1000 |

| Weight(kg) | 1700 |

| Size(mm) | 250*800*3400 |

The tire rubber powder production line operates at room temperature. It can achieve tire crushing, tire wire separation, fiber separation, and tire powder making at one time. During the process, no wastewater, waste gas, or dust is generated, which meets environmental protection requirements. It can produce fine rubber powder below 30 meshes. The size of the rubber powder can be customized into different meshes according to demand. After the rubber powder is restored, it can replace natural rubber to make thousands of rubber products.

Input

- Car tires

- Truck tires

- Agricultural tires

Output

- Tire chips

- Rubber granulate

- Rubber powder

- Steel wire

Textile fluff

Benefits: Recycling of used tires

- Variable throughput depending on requirements

- Purity of rubber granulate > 99.9%

- Granulating, grinding, and powdering to <1 mm

Processing line can be easily expanded due to modular design

The Recyclability and Value of Scrap Tires

Tires are an important part of cars. With the increasing number of motor vehicles around the world, the disposal of waste tires has become an urgent problem.

Beyond controlling the negative effects of abandoned end-of-life tires, recycling tires provides opportunities to breathe new life into them. Based on our grading structure completed by industry experts, we can resell them. If they can’t be used on a vehicle again, we break down the scrap tires into their raw materials – rubber powder and granulate, steel wire and fire – and work with manufacturers to help them create a wide variety of safe, sustainable products.

Manufacturers use recycled rubber in everything from rubber mulch for playgrounds and garden beds to vehicle mud guards, speed bumps and anti-fatigue mats. Construction companies also use scrap tire materials for their work, while athletic installers use recycled rubber for cushioning of equestrian surfaces, tracks and athletic fields. The possibilities are endless.

Economic Value:Recycling scrap tires has become a profitable industry with considerable potential for growth.the materials derived from scrap tires can be quite valuable:

1.Steel Wire:Tires usually contain steel wires, which are used to strengthen the structure and durability of the tire. Steel wires account for about 15% of the tire's weight.Extracted steel wire can be sold

2.Rubber Powder: Rubber is the main component of tires, accounting for about 60% of the total weight of tires. is utilized in various applications including road construction, fall protection mats,sports surfaces, and rubber products.

3.Fiber: The tire also contains a certain amount of fiber material, which is used to increase the strength and wear resistance of the tire. The fiber accounts for about 5-10% of the tire weight.industry while the textile components are used as an alternative fuel.

4.Other Products:Scrap tires can also be processed into crumb rubber, tire-derived fuel (TDF), and civil engineering materials.

As technology continues to evolve, the methods for processing and utilizing these materials will likely become more efficient, further enhancing the profitability and sustainability of scrap tire recycling. Therefore, promoting the recycling of scrap tires not only addresses a significant waste management issue but also opens up opportunities for economic growth and environmental conservation.