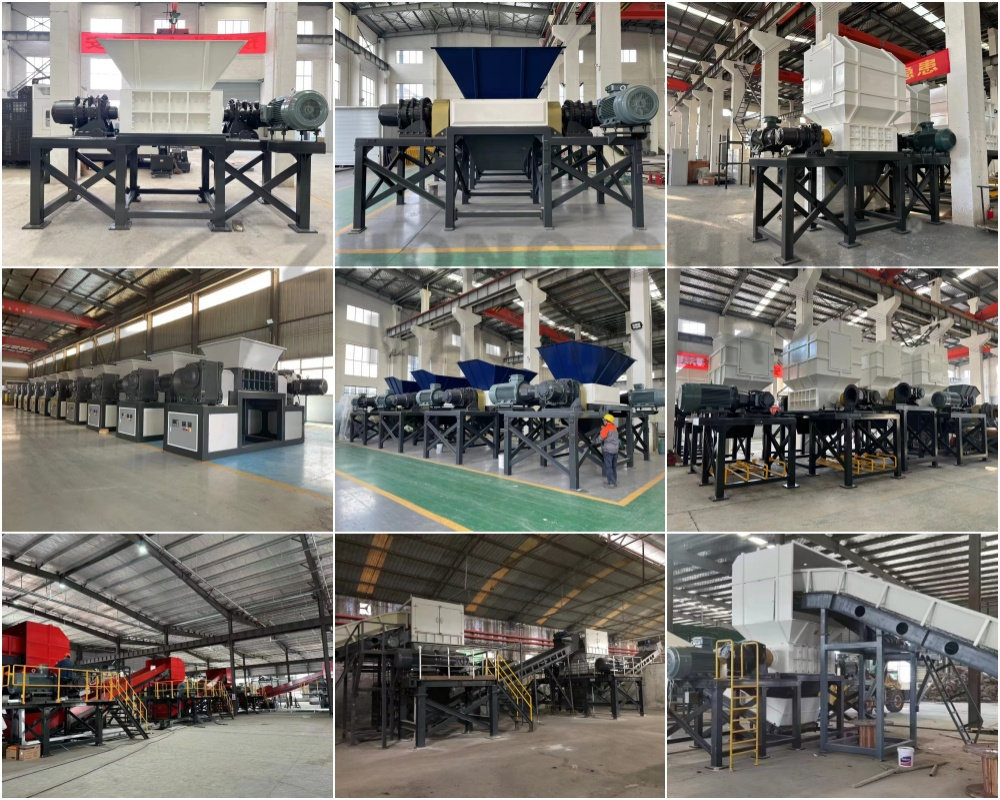

Double-Shaft Shredder

-

Production Capacity:

1000-10000 kg/h

-

Applicable Industries:

Waste metal recycling industry, Building material stores, Household waste, Large waste treatment plants, Manufacturing plants, Restaurants, Farms, Government, Retail, Energy and mining, Construction engineering

-

Power:

7.5-110Kw

-

Core Components:

CE / ISO:9001

-

Place of Origin:

Henan, China

- Product Details

- Characteristics

- Working Principle and Application

- Parameters

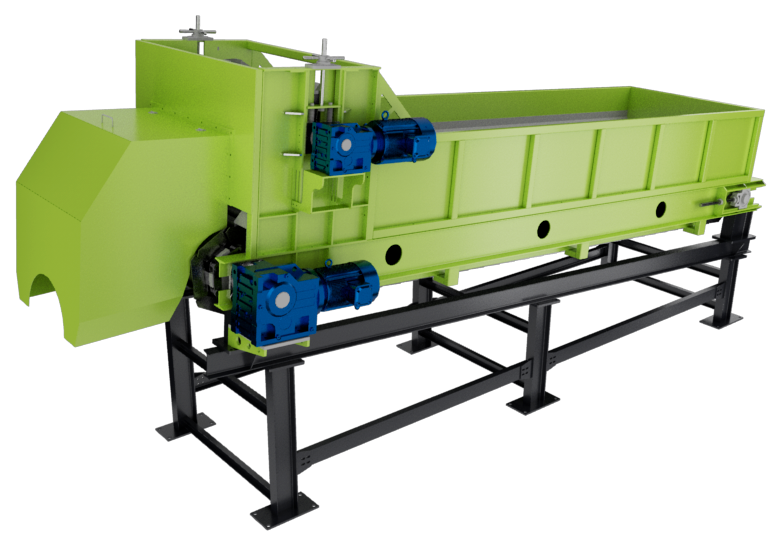

The shredder composed of motor, reducer, blade, shaft, frame, base, box, working platform.

The main equipment of the shredder adopts high-quality steel plate welding machining to ensure the stability.

The bearing seat adopts the patented split and is an easy to remove type, which can quickly.

the moving blade, fixed blade, bearing ,easy to maintain and replace the blade.

The double shaft independent drive is adopted, so that the materials are pressed accordingly during production to achieve the automatic feeding function.

The unique cutter shaft structure will not entangle the shaft or block.

The equipment in the production process of low speed and high torque, to improve the production efficiency.

-

01High shredding power, all the blades are made of alloy steel, firm and long service life

-

02PLC automatic control is adopted, with start, stop, reverse and overload automatic reverse control functions

-

03Configurable feed conveyor belt helps save labor and improve efficiency

-

04Easy adjustment, low maintenance cost, economy and durability

This is a multi-purpose double shredder suitable for industrial and commercial waste, bulky waste, kitchen waste, urban green waste, construction waste, paddy straw shredder etc.

It includes various plastics, cardboard, metals, fibers, leather, wood, glass, tires, electronic accessories, various large furniture, kitchen waste, disposal of slaughtered animals, waste wood, crop straw or fruit shells and other waste designed.

The motor drives the reducer and transmits the torque to the shredder's cutters through the cutter roller shaft, which hooks the material and tears it downwards, while the cutters on the relative rollers act like scissors to cut the material. Reducing the size of the material.

The shredded material is discharged from the bottom of the shredder, greatly reducing space occupation and disposal costs for recycling, incineration, or landfill.

The shredding efficiency is high, and we also have other crushing equipment and sorting equipment that can efficiently Secondary crushing and sort the torn materials. Working with a production line.

| Model | 600 | 800 | 1000 | 1200 | 1400 | 1600 | 1800 |

| Motor(kw) | 11*2 | 18.5*2 | 35*2 | 45*2 | 55*2 | 75*2 | 110*2 |

Reducer | P6-P7 | P7-P8 | P8-P10 | P10-P12 | P11-P13 | P12-P16 | P14-P16 |

| Siemens or other motors, planetary reducers or other reducers can be customized according to customer requirements | |||||||

| Rotation Speed | 8-20rmp | 8-20rmp | 8-15rmp | 8-15rmp | 8-15rmp | 8-12rmp | 8-12rmp |

| Blades Diameter | 220-320 | 260-320 | 260-400 | 400-500 | 400-500 | 500 | 500 |

| Blades material | The material of the blades (55sicr, 5crsi, 9crsi, skd11, m6v, h13) can be customizedaccording to the customer's actual usage | ||||||

| Feeding Size | 1200*900mm | 1400*1000mm | 1600*1200mm | 1800*1300mm | 2000*1300mm | 2200*1700mm | 2400*2000mm |

| The size and appearance of the feeding hopper can be customized according to thecustomer's feeding situation | |||||||

| Weight(kg) | 1800 | 2500 | 3700 | 5500 | 7500 | 9500 | 13000 |

-

Bag OpenerBag opener or bag opener system is a mechanical device used to automatically open and empty bags containing bulk materials. This system is commonly used in indu...Get Quote

Bag OpenerBag opener or bag opener system is a mechanical device used to automatically open and empty bags containing bulk materials. This system is commonly used in indu...Get Quote -

Jaw CrusherThe working principle of jaw crusher Although the jaw crusher has various structural types, its working principle is the same, that is, the material is crushed ...Get Quote

Jaw CrusherThe working principle of jaw crusher Although the jaw crusher has various structural types, its working principle is the same, that is, the material is crushed ...Get Quote -

Hydraulic Cone CrusherHydraulic Cone Crusher integrates machinery, hydraulic pressure, electrics, automation, and intelligent control, which can be used for medium crushing, fine cru...Get Quote

Hydraulic Cone CrusherHydraulic Cone Crusher integrates machinery, hydraulic pressure, electrics, automation, and intelligent control, which can be used for medium crushing, fine cru...Get Quote -

Mobile Jaw Crusher PlantMobile jaw crushing station is a novel rock crushing equipment, also known as mobile crushing station. The purpose of its design concept is to stand from the cu...Get Quote

Mobile Jaw Crusher PlantMobile jaw crushing station is a novel rock crushing equipment, also known as mobile crushing station. The purpose of its design concept is to stand from the cu...Get Quote