Trommel screen

-

Production Capacity:

80-200m³/h

-

Applicable Industries:

Construction & Demolition / Commercial Waste /Commingled Plastics / Fiber Sorting / Scrap Recycling

-

Power:

11kw-30kw

-

Core Components:

Cast rolling ring/Polyurethane drive wheel

-

Place of Origin:

Henan, China

- Product Details

- Characteristics

- Working Principle and Application

- Parameters

Waste trommel screen, waste sorting machines, waste recycling plants, waste processing machines, waste processing plants, waste recycling machines

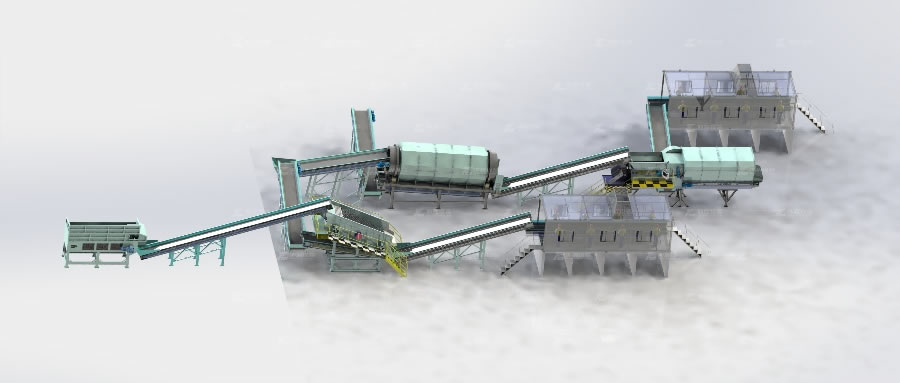

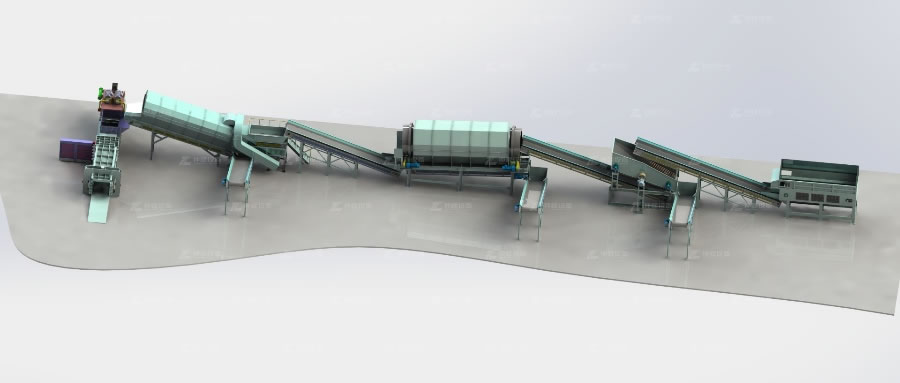

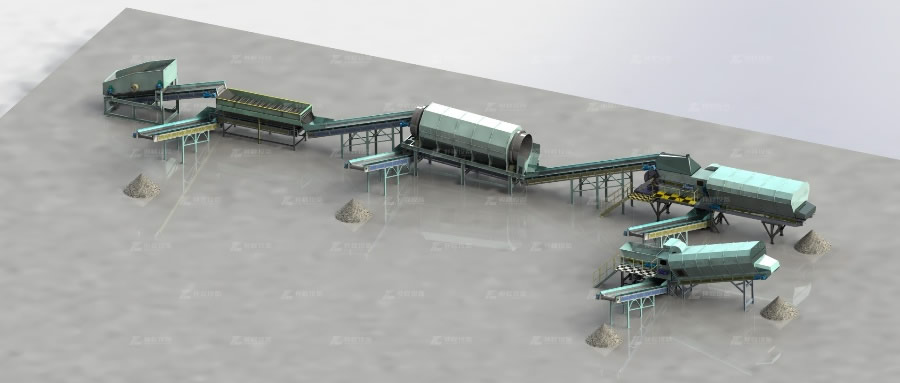

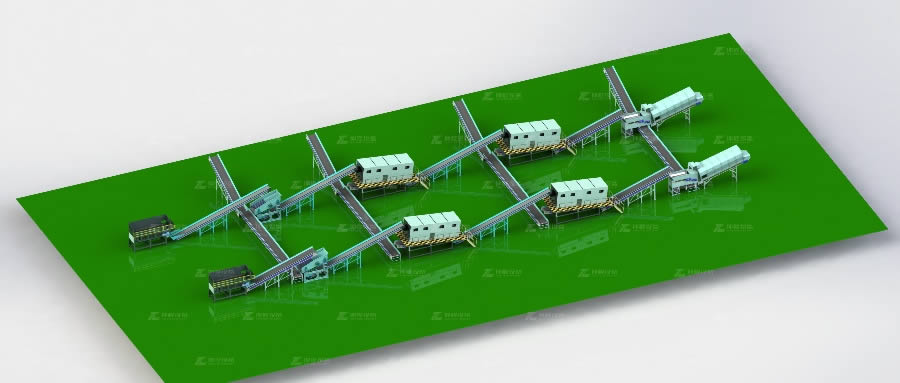

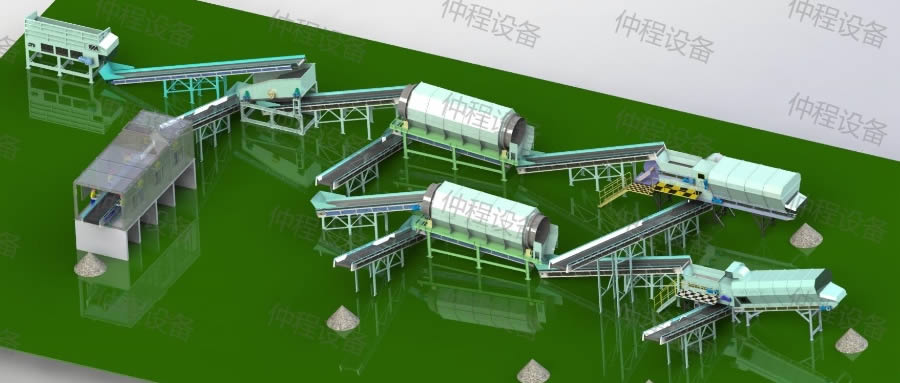

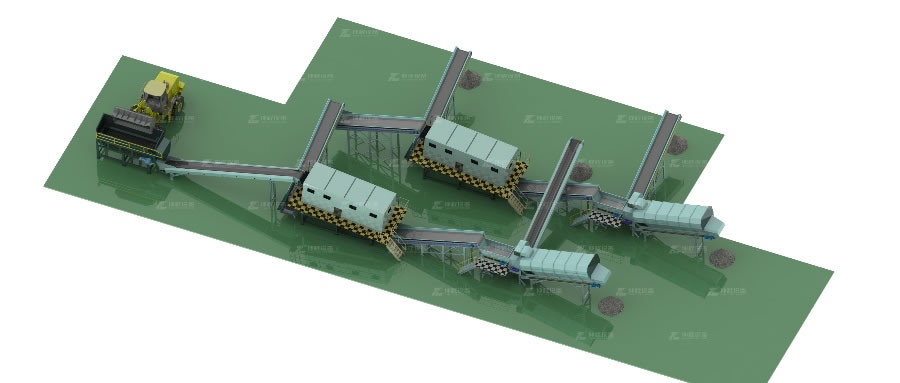

Trommel screen plants for the separation of municipal solid waste(MSW),landfills,C&D waste recycling,composting plants, recycling centres, earthworks ,industrial,wood and plastic.

Trommel screens are the machines which separates the waste according to predetermined sizes. This process occurs with help of the drum inside of the trommel screen which has holes with certain diameter. Availability of changing sheet metals of the drum allows the machine to sort wastes in different dimensions. We manufacture trommel screen according to required capacity and demands.

Trommel Screen Advantages:

Efficiency: High throughput and effective separation of materials.Trommel screens excel at separating materials by size. The perforated drum allows smaller particles to pass through while larger ones are retained and carried to the end of the drum for further processing or disposal.

Versatility: Can handle a wide range of materials and varying feed sizes. Can process a wide variety of materials, including soil, compost, sand, gravel, municipal solid waste, and even large rocks. This versatility makes trommel screens valuable in recycling, mining, and aggregate industries.

Customization: Screens can be customized with different hole sizes and configurations to meet specific needs.

Trommel Screen Considerations:

Maintenance: Regular maintenance is required to ensure optimal performance and longevity.

Clogging: Fine or sticky materials may clog the screens, requiring periodic cleaning.

Space and Power: Trommel screens require sufficient space and power to operate efficiently.

-

01Improved Screening Efficiency: The rotating motion of the drum helps to break up clumps and keep materials in constant motion, reducing the likelihood of blinding (when particles clog the screen openings) and improving overall screening efficiency.

-

02Dust and Noise Reduction: Trommel screens are often enclosed, which helps to contain dust and reduce noise levels. This makes them more suitable for use in urban or environmentally sensitive areas.

-

03Low Operating Costs: Trommel screens generally have lower operating costs compared to other screening methods. They are energy-efficient and require less power to operate. The simplicity of the design also means fewer parts are prone to wear and tear, reducing maintenance costs.

-

04Durability and Longevity: Constructed from heavy-duty materials, trommel screens are designed to withstand harsh conditions and abrasive materials. This durability ensures a long operational life even in demanding environments.

How It Works:

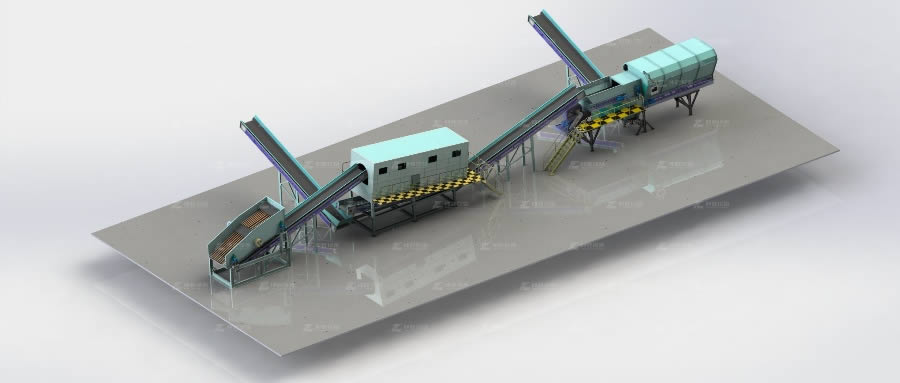

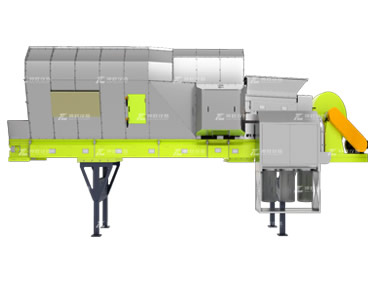

Rotating Drum: The trommel screen consists of a rotating cylindrical drum with perforated holes of varying sizes.

Feed Hopper: Waste material is fed into the drum through a hopper.

Rotation and Screening: As the drum rotates, waste materials are lifted and tumbled within the drum. Smaller particles fall through the perforations, while larger particles continue to move along the drum until they exit at the end.

Separation: The materials are thus separated based on size, with finer materials passing through the screen and larger materials being discharged.

Key Components:

1.Drum: A cylindrical drum with perforated screens.2.Feed Hopper: An entry point for the waste material.3.Support Structure: Framework that supports the drum.4.Motor and Gearbox: Provides the rotational force needed for the drum.5.Discharge Chutes: Outlets for separated materials.

Applications:

Municipal Solid Waste (MSW) Processing: Separating recyclable materials from non-recyclable waste.

Composting: Screening organic material to create uniform compost.

Mining and Quarrying: Classifying aggregates and separating valuable minerals.

Recycling Facilities: Sorting and classifying various types of waste like plastics, metals, and paper.

Construction and Demolition Waste: Separating reusable materials from rubble and debris.

Zhongcheng offers a wide range of trommels with different diameters, screening lengths and plate thickness, depending on the equipment application: simple double trommels for urban treatment plants, refine trommels, trommels for construction and demolition waste treatment facilities, etc.

Customer Questions and Answers:

1.What is the differences between waste trommle and compost trommel screen?

2.What are the main factors influencing the separation efficiency and output of a drum screening machine?

Quite often, waste material is delivered to recycling centres in black bags, meaning that in some recycling lines, the bags need to be split open by hand. To avoid this, and to make the recycling process more efficient, bag opener systems can be added to the trommel. These ‘teeth’ allow the bags to be opened within the drum, ready for screening.

When thinking about specifying a screening solution, it is important to consider five key areas:

1) What do you want to achieve?

2) What are you sorting? Will this change?

3) What space is available for the equipment?

4) Logistics of running the equipment – Is there enough space for inputting and collecting materials.

5) What budget is available?

A common use for trommels is to remove glass from waste streams. Glass, as a material, can be recycled over and over again, enhancing the benefits in the long term. Furthermore, scope for the use of recycled glass is incredibly diverse, allowing businesses to make significant amounts of money from its sale. Recycled glass can be sold on and used in many areas, including the manufacture of bricks, fibreglass, sports turf, tarmac and aggregates.

Waste trommel screen, waste sorting machines, waste recycling plants, waste processing machines, waste processing plants, waste recycling machines

| Model | Length Range | Segment No. | Aperture Size | Power (Kw) | Inclined Angle | Max. Material Size | Rotating Speed(rpm) |

| ZCφ600 | 2-4m | 1-2 | ≤30mm | 2.2-3 | 0-7° | 60mm | 12-18 |

| ZCφ800 | 2-5m | 1-3 | ≤50mm | 3-5.5 | 0-7° | 100mm | 12-18 |

| ZCφ1000 | 2-6m | 1-4 | ≤100mm | 4-11 | 0-7° | 150mm | 10-18 |

| ZCφ1200 | 3-8m | 1-4 | ≤150mm | 5.5-18.5 | 0-7° | 200mm | 9-15 |

| ZCφ1500 | 3-10m | 1-5 | ≤200mm | 7.5-22 | 0-7° | 250mm | 9-15 |

| ZCφ1800 | 4-12m | 1-5 | ≤220mm | 7.5-22 | 0-7° | 270mm | 8-15 |

| ZCφ2000 | 5-15m | 1-5 | ≤250mm | 11-30 | 0-7° | 300mm | 8-12 |

| ZCφ2500 | 5-18m | 1-6 | ≤300mm | 11-30 | 0-7° | 350mm | 8-12 |

customized according to your requirements

-

Vibrating ScreenVibrating screen is a mechanical device used to separate materials into different sizes and grades by vibrating them through a mesh or screen. This equipment is...Get Quote

Vibrating ScreenVibrating screen is a mechanical device used to separate materials into different sizes and grades by vibrating them through a mesh or screen. This equipment is...Get Quote -

WindshifterWindshifter (Air Drum Separator ) is the ideal solution for separating all kind of waste types into two fractions, heavy and light. The robust construction and ...Get Quote

WindshifterWindshifter (Air Drum Separator ) is the ideal solution for separating all kind of waste types into two fractions, heavy and light. The robust construction and ...Get Quote -

Drum Screen RecyclingDrum screen machines are primarily used for material screening, helping to sort and recycle municipal solid waste and screen landfill waste. Their efficiency an...Get Quote

Drum Screen RecyclingDrum screen machines are primarily used for material screening, helping to sort and recycle municipal solid waste and screen landfill waste. Their efficiency an...Get Quote -

Ballistic SeparatorBallistic separators are a crucial component in modern recycling and waste management systems, contributing to more efficient resource recovery and environmenta...Get Quote

Ballistic SeparatorBallistic separators are a crucial component in modern recycling and waste management systems, contributing to more efficient resource recovery and environmenta...Get Quote