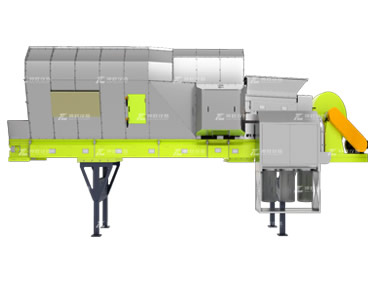

Disc Screen

-

Production Capacity:

35-200m³/h

-

Applicable Industries:

MSW/C&D/Multi-material/Biomass/Organic/Tires/Plastic/Wood/Paper and Carboard

-

Power:

15kw

-

Core Components:

Sieve plate、PLC

-

Place of Origin:

Henan, China

- Product Details

- Characteristics

- Working Principle and Application

- Parameters

The Zchmachinery disc screen makes the separation of the dry and wet fraction of municipal solid waste simpler, more effective, and economically advantageous. Municipal solid waste screening systems are capable of separating up to 100 T/H using just 15 kW of power.

In the case of municipal solid waste, screening is fundamental as it helps municipalities and private companies that use MSW shredders and grinders to simplify the recycling process as much as possible. This process applies to both the separation of the organic fraction from the municipal solid waste to be transformed into compost or biogas, and the separation of the light fraction for the production of RDF (Refuse-derived fuel). When the municipal solid waste is adequately separated by innovative screening solutions that guarantee the best results, both can be transformed into high-quality materials and put back on the market.

-

01Excellent material agitation and separation

-

02Patented in-line discs provide accurate sizing of material, reducing product loss

-

03Disc and shaft design reduces material wrap, increasing uptime

-

04Small footprint,Low power consumption

As a specialized manufacturer, we deliver robust, reliable screening technology designed to excel across the widest spectrum of materials.

Unmatched Material Versatility:

Municipal Solid Waste (MSW): Efficiently separate organics, fines, and recyclables.

Single Stream Recycling: Accurately size and classify mixed recyclables for downstream purity.

Construction & Demolition (C&D): Separate fines, soil, wood, and bulky materials.

Wood Waste: Classify chips, shavings, sawdust, and larger wood pieces.

Compost & Green Waste: Remove contaminants, oversize materials, and achieve desired particle size.

Plastics: Prepare mixed plastics streams for further sorting (PET, HDPE, etc.).

Glass: Separate cullet by size and remove contaminants.

Tires (TSR): Size tire shreds and remove fines/fluff.

And More: Effectively handles biomass, SRF/RDF fractions, industrial waste, and other challenging materials.

Why Choose Our Disc Screens (Star Screens)?

Superior Sizing Accuracy: Precision-engineered disc shafts and optimized disc patterns ensure consistent and efficient separation based on particle size, maximizing product purity and recovery rates.

Exceptional Throughput & Efficiency: High-capacity design handles large volumes of material continuously, minimizing downtime and maximizing processing output.

Unparalleled Anti-Wrapping Design: Our unique disc geometry and shaft configuration are proven to resist wrapping by wires, textiles, films, and other problematic stringy materials – a critical advantage in waste processing.

Robust Construction & Durability: Built with heavy-duty components (high-grade steel, wear-resistant discs, reinforced shafts, robust bearings) to withstand the harshest abrasives and impacts, ensuring long service life and low operating costs.

Low Maintenance & Easy Servicing: Modular disc design allows for quick and easy replacement of individual discs or shafts, minimizing maintenance downtime. Sealed bearing housings enhance protection.

Optimized Flow & Reduced Blockages: Intelligent shaft layout and disc arrangement promote smooth material flow, prevent bridging, and reduce the risk of blockages.

Customizable Configurations: Available in various sizes, disc diameters, shaft spacings, deck configurations (single, double, triple deck), and discharge options to perfectly match your specific feed material, target fractions, and throughput requirements.

Proven Reliability: Engineered and manufactured for 24/7 operation in critical waste sorting and recycling facilities worldwide.

Core Benefits for Your Operation:

Increased Purity: Deliver cleaner fractions (overs, middlings, unders) to downstream processes.

Enhanced Recovery: Maximize yield of valuable recyclable materials.

Reduced Landfill Costs: Effectively divert fines and contaminants.

Lower Operating Costs: Minimize downtime, maintenance, and power consumption.

Optimized Downstream Processing: Prepare material streams efficiently for shredders, optical sorters, air classifiers, balers, etc.

Reliable Performance: Achieve consistent results under demanding conditions.

Ideal For:

Material Recovery Facilities (MRFs)

Waste-to-Energy (WtE) Plants

Construction & Demolition Recycling Centers

Composting & Organic Waste Processing Facilities

Wood Recycling Yards

Plastics Recycling Plants

Glass Cullet Production

Tire Shredding (TSR) Operations

Advanced Waste Treatment Plants

Manufactured for Excellence. Built to Last.

As a dedicated manufacturer, we combine deep engineering expertise with stringent quality control to produce Disc Screens (Star Screens) that deliver outstanding performance, durability, and return on investment. We provide comprehensive support, from design consultation to after-sales service.

Ready to Optimize Your Waste Sizing?

Request a Detailed Specification Sheet

Get a Customized Quote for Your Application

Speak with Our Screening Experts Today!

ZCH Machinery- Engineering Efficiency in Waste Processing

-

Ballistic SeparatorBallistic separators are a crucial component in modern recycling and waste management systems, contributing to more efficient resource recovery and environmenta...Get Quote

Ballistic SeparatorBallistic separators are a crucial component in modern recycling and waste management systems, contributing to more efficient resource recovery and environmenta...Get Quote -

Disc ScreenDisc screen, also known as a disc scalping screen, is a mechanical device used to separate materials based on size. It is commonly used in industries such as wa...Get Quote

Disc ScreenDisc screen, also known as a disc scalping screen, is a mechanical device used to separate materials based on size. It is commonly used in industries such as wa...Get Quote -

Drum Screen RecyclingDrum screen machines are primarily used for material screening, helping to sort and recycle municipal solid waste and screen landfill waste. Their efficiency an...Get Quote

Drum Screen RecyclingDrum screen machines are primarily used for material screening, helping to sort and recycle municipal solid waste and screen landfill waste. Their efficiency an...Get Quote -

WindshifterWindshifter (Air Drum Separator ) is the ideal solution for separating all kind of waste types into two fractions, heavy and light. The robust construction and ...Get Quote

WindshifterWindshifter (Air Drum Separator ) is the ideal solution for separating all kind of waste types into two fractions, heavy and light. The robust construction and ...Get Quote