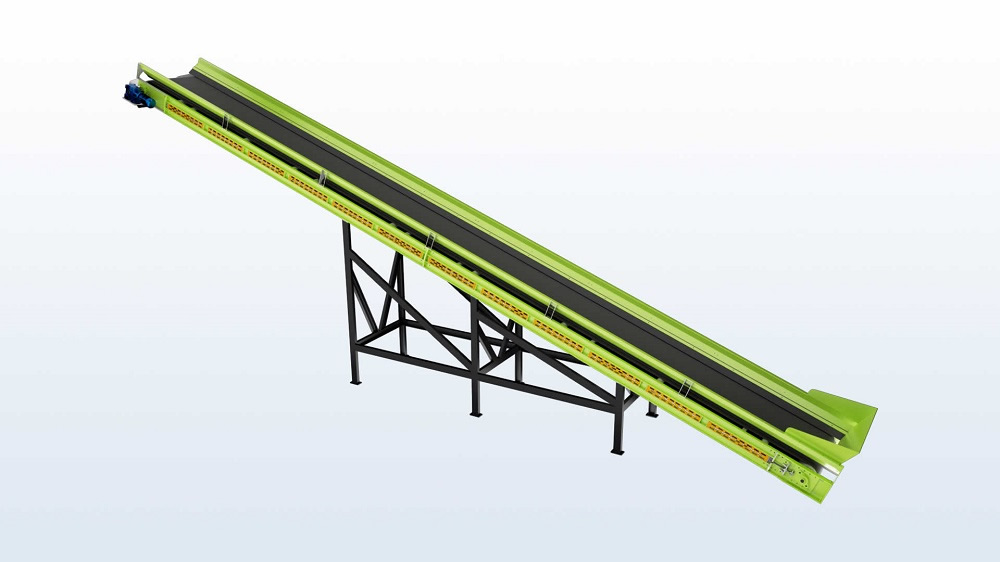

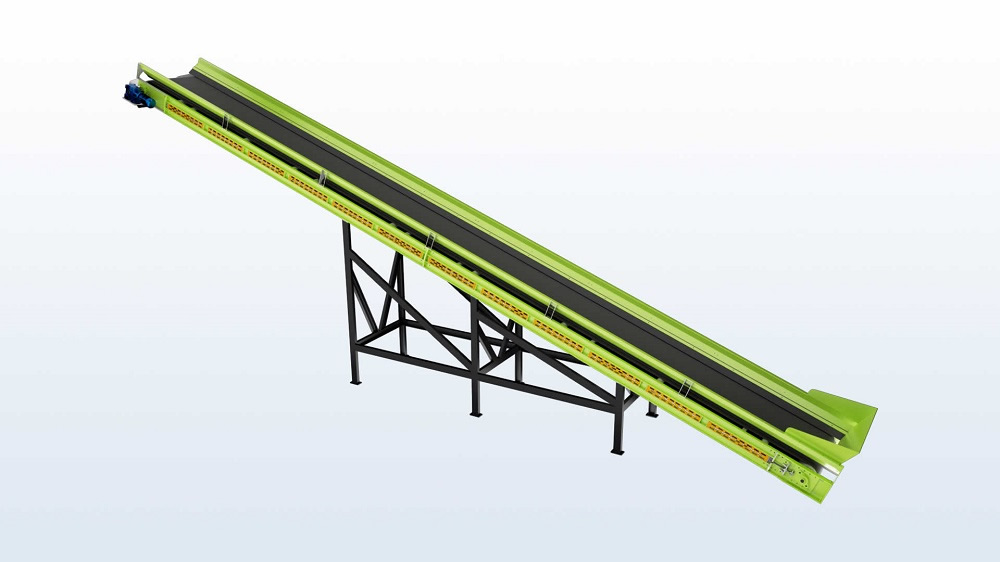

Conveyor Belt

-

Production Capacity:

80-300m³/h

-

Applicable Industries:

Wood Biomass Files and data Paper and cellulose Domestic and industrial waste Alternative fuel Plastics - post-consumer Plastic - post-industrial Plastic - Inhouse Recycling All

-

Power:

3 - 30 kW

-

Core Components:

CE / ISO:9001

-

Place of Origin:

Henan, China

- Product Details

- Characteristics

- Working Principle and Application

- Parameters

Belt conveyor is one of the carrying or transporting mechanisms of a recycling or waste management installation. Depending on the complexity of the waste materials mixture, the looping belt requires robust and durable properties to resist impact, wear and leaking of oil and grease.

With our flat and trough belt conveyors of the series, you get continuous conveyors of modular design with which you can transport various bulk materials safely. With a particularly resistant oil- and grease-resistant rubber belt, designed for maximum conveying capacity in continuous operation and the option of installing various belt cleaning, safety and monitoring systems, the flat- / trough belt conveyor is ideally suited for transporting a wide range of materials such as wood, biomass, waste, metals, plastics, substitute fuels, etc.

As waste materials build up across a distribution centre, our conveyor systems are engineered to fit around existing infrastructure so they remove the waste materials while keeping warehouse operations utterly free of disruption. Made from modular components, ZCH conveyor systems are built to last and run 24/7 in harmony with your operations.

-

01design can be designed in rising or falling form

-

02Flat or moulded belt construction

-

03Lower belt / upper belt covering available

-

04Durable and high-quality materials/Long-term maintenance free

With a particularly resistant oil- and grease-resistant rubber belt, designed for maximum conveying capacity in continuous operation and the option of installing various belt cleaning

| BC800 | BC1000 | BC1200 | BC1400 | BC1600 | |

| Belt Width | 800mm | 1000mm 1 | 200mm | 1600mm | 1800mm |

| Length | optional | optional | optional | optional | optional |

| Belt Speed | <1.2m/s | <1.2m/s | <1.2m/s | <1.2m/s | <1.2m/s |

| Installation | angle < 21° | angle < 21° | angle < 21° | angle < 21° | angle < 21° |

| Throughput | 20-30m³/h | 40-50m³/h | 60-70m³/h | 80-90m³/h | 90-100m³/h |

| Power | >3Kw | >3Kw | >3Kw | >3Kw | >3Kw |

-

Conveyor BeltGarbage conveyor/Trash conveyor belt system is a processing line to classify paper, plastic, metal, glass, and organic matter and realize the recycling of rubb...Get Quote

Conveyor BeltGarbage conveyor/Trash conveyor belt system is a processing line to classify paper, plastic, metal, glass, and organic matter and realize the recycling of rubb...Get Quote -

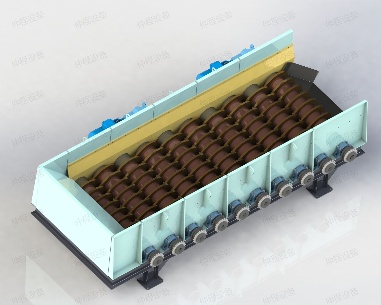

Vibrating FeederA vibrating feeder is a mechanical device used to convey materials, typically in bulk, from one location to another in a controlled manner. This equipment is co...Get Quote

Vibrating FeederA vibrating feeder is a mechanical device used to convey materials, typically in bulk, from one location to another in a controlled manner. This equipment is co...Get Quote -

Apron FeedersApron Feeder is a conveyor manufactured from steel plates driven by steel chains wearing on steel surfaces. They are a robust design manufactured for durability...Get Quote

Apron FeedersApron Feeder is a conveyor manufactured from steel plates driven by steel chains wearing on steel surfaces. They are a robust design manufactured for durability...Get Quote -

Wobbler FeederWobbler feeder is a type of feeding equipment that uses rotating elliptical bars, known as wobblers, to separate materials based on size and type before they re...Get Quote

Wobbler FeederWobbler feeder is a type of feeding equipment that uses rotating elliptical bars, known as wobblers, to separate materials based on size and type before they re...Get Quote