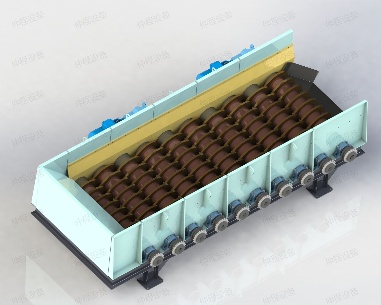

Vibrating Feeder

-

Production Capacity:

80~200m³/h

-

Applicable Industries:

Vibrating feeder is used to feed block and granular materials uniformly, regularly and continuously from the storage bin in to stone crushers. Also it could separate the raw materials primarily by grate plate.

-

Power:

7.5kw-22kw

-

Core Components:

Spring Base,Vibrator,Bottom Plate

-

Place of Origin:

Henan, China

- Product Details

- Characteristics

- Working Principle and Application

- Parameters

After the material enters the garbage vibrating screen, the vibrating motor drives the screen surface to move upward and forward in a straight line.

Municipal solid waste (MSW), commonly known as trash, garbage or rubbish, is a type of waste that generally consists of everyday items, such as food packaging, food scraps, clothing, appliances, newspapers, bottles, yard waste, etc. Zhongcheng can provide material recovery facilities with solutions for screening, sizing and shredding MSW. Recycling equipment from Zhongcheng can cut maintenance costs, increase automation and maximize uptime for facilities utilizing single-stream recycling. Zhongcheng technology has been proven to divert MSW from entering landfills by sorting, separating and recovering valuable commodities.

-

01Robust, all-welded feeder body with high sidewalls preventing spillage and simplify feed chute design. Can be mounted on support springs or suspended on coil springs, depending on the location and application

-

02Heavy-duty vibrators lubricated for life minimizing maintenance. High-capacity vibrator motors generate up to 10mm stroke in most of materials from small granular materials to large lumps

-

03Feed rate adjusted by repositioning weight segments in the drive or by using variable speed control.

-

04Replaceable AR bolted wear liners on sides and pan. Many feeder lengths make installation flexible and can reduce your total cost of installation

Working principle

Vibrating feeder is made of vibrating frame, spring, vibrator, motor vibrating device and motor. The vibrator consists two fixed eccentric shafts whose gears are jogged. When installation, the two gears must be jogged according to the sign. By drive of the motor, the two eccentric shafts start rotating to generate a linear huge power which forces the feeder to vibrate back and forth. Through the vibration, The materials will slip and sling on the funnel, moving forward, when the materials pass the screening part, smaller material will fall down, avoiding the further crushing, so screening purpose is reached.

Municipal solid waste products are items that are discarded by the public and need to be either manually or mechanically sorted for further processing at a materials recovery facility, also known as an MRF, or sent to landfills. The composition of MSW material can vary greatly from municipality to municipality based on the development of each municipality’s recycling system. Some municipalities require their citizens to sort their waste products, while other municipalities use a single-stream recycling system or a mostly single-stream recycling system. Single-stream recycling refers to a system that does not require the sorting and separation of recyclable materials. In single-stream recycling, both the collection and processing systems are designed to handle fully commingled mixtures of recyclables. Using single-stream recycling means that all recyclable materials are placed into one bin for collection by a single truck, including paper, plastics, cardboard, glass, aluminum, metals and more. Recyclables are then transported to a materials recovery facility, or MRF, where they are separated, sorted and sold for reuse.

| Model | Trough size(mm) | Max feed size(mm) | Capacity (t/h) | Motor Power (kw) |

| ZSW-650*2500 | 650*2500 | 560 | 50-80 | 5.5 |

| ZSW-850*3000 | 850*3000 | 780 | 80-120 | 7.5 |

| ZSW-960*3800 | 950*3800 | 820 | 120-210 | 11 |

| ZSW-1100*4200 | 1100*4200 | 1000 | 200-430 | 15 |

| ZSW-1100*4900 | 1100*4900 | 1000 | 280-500 | 15 |

| ZSW-1300*4900 | 1300*4900 | 1100 | 450-600 | 22 |

| ZSW-1500*6000 | 1500*6000 | 1280 | 550-1200 | 30 |

| ZSW-1800*6000 | 1800*6000 | 1350 | 600-1200 | 37 |

*The output will vary according to different materials, feed particle size and other factors

-

Wobbler FeederWobbler feeder is a type of feeding equipment that uses rotating elliptical bars, known as wobblers, to separate materials based on size and type before they re...Get Quote

Wobbler FeederWobbler feeder is a type of feeding equipment that uses rotating elliptical bars, known as wobblers, to separate materials based on size and type before they re...Get Quote -

Apron FeedersApron Feeder is a conveyor manufactured from steel plates driven by steel chains wearing on steel surfaces. They are a robust design manufactured for durability...Get Quote

Apron FeedersApron Feeder is a conveyor manufactured from steel plates driven by steel chains wearing on steel surfaces. They are a robust design manufactured for durability...Get Quote -

Waste FeederWaste feeder was specially designed to optimize municipal solid waste sorting systems. The Drum Feeder ensures that your sorting system, baler or shredder has a...Get Quote

Waste FeederWaste feeder was specially designed to optimize municipal solid waste sorting systems. The Drum Feeder ensures that your sorting system, baler or shredder has a...Get Quote -

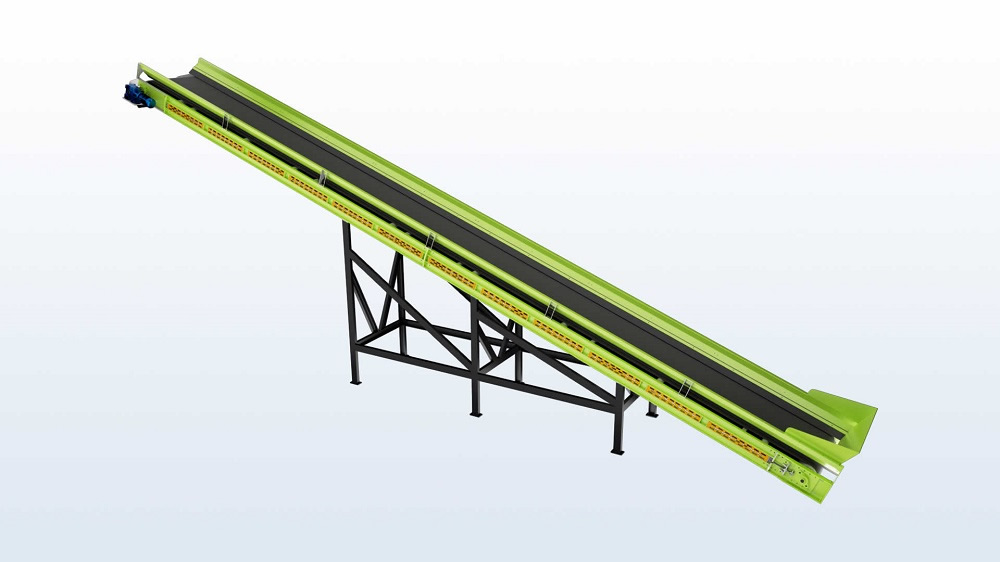

Conveyor BeltGarbage conveyor/Trash conveyor belt system is a processing line to classify paper, plastic, metal, glass, and organic matter and realize the recycling of rubb...Get Quote

Conveyor BeltGarbage conveyor/Trash conveyor belt system is a processing line to classify paper, plastic, metal, glass, and organic matter and realize the recycling of rubb...Get Quote