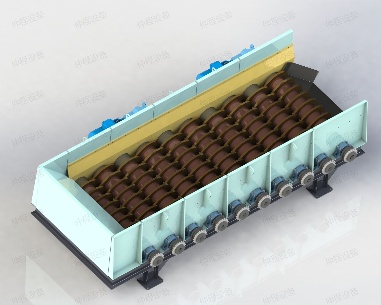

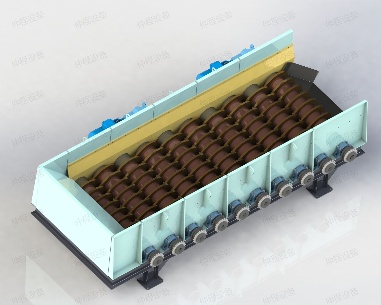

Wobbler Feeder

-

Production Capacity:

50-600t/h

-

Applicable Industries:

rock quarries, sand and gravel, mining, construction and demolition recycling, construction aggregates, road and railway construction, metallurgy, water conservancy and chemical industry.

-

Power:

18.5-55kw

-

Core Components:

Solid shafts/ Heavy Duty Chains and Sprockets

-

Place of Origin:

Henan, China

- Product Details

- Characteristics

- Working Principle and Application

- Parameters

Disk feeders, known also as “wobbler” feeders, contain a number of disks mounted side by side at an appropriate distance and that rotate to carry any materials placed on them. The disk cross-section may be in the form of an ellipse, triangle or circle.

By adjusting the clearances in a wobbler feeder, it is possible to separate fine materials of various sizes before reaching the crusher, and to filter aggregate of two or even three sizes. Fine materials of different sizes passing underneath the feeder can then be directed to separate belts. Thanks to this feature, wobbler feeders both feed the crusher as a primary operation, and also sort (screen) the materials.

Wobbler Feeder is used in aggregate and mining applications to sort the run-of-mine material before the primary crusher.

Especially in case of difficult to screen, wet, sticky bulk materials kind of feeding and scalping distinctly outclasses the traditional screening machines,

which frequently show baking and adhesions with these materials.

-

01Can cope with wet and sticky material without clogging Excel where others fail in situations too wet and sticky for other feeders and scalpers.

-

02Requires much less maintenance than a scalper Self-cleaning and designed to resist clogging and reduce blinding.

-

03Increases final product quality without the need for washing Recommended for pre-screening and cleaning of dirty material with a high content of clay and moisture.

-

04Increases total output as it reduces the waste Scalping the feed reduces the amount of material going into the primary crusher, it also reduces the required size and capacity of the crusher needed.

What is the operating principle behind Wobbler Feeders?

The triangular, elliptical or circular disks rotate synchronously, carrying the material over the feeder and separating finer materials through the bottom. As a result, a more homogenous material is provided to the following phase.

Wobbler feeders, known also as disk feeders, can be produced in sizes of 1–2 meters wide and 3–8 meters long, as required. Two or three disk feeders can be set up in sequence for longer distances.

In wobbler feeders, the disks are rotated by a powerful gearbox-governed electric motor with a single gear, although it is also possible to rotate each disk from a separate motor. If necessary, the fine aggregate that passes through the disks can be fed to the belt to form a bed for the crushed rock exiting the crusher, thus slowing the wear and tear on the rubber band.

For what processes/applications are Wobbler Feeders used?

Wobbler feeders are the most appropriate type of feeder when working with moist and sticky materials. Handling and screening moist and muddy material can be difficult, and blockages to the system can be frequent. Wobbler feeders can easily feed materials with a high moisture content to crushers.

The synchronized rotation of self-cleaning elliptical disks on circular-section disks ensures the removal of moist and sticky materials from the coarse material through compression and friction forces. Material passing through the disks can be separated or mixed with material as it exits the crusher. These feeders can manage the requirements of demanding working conditions, will also producing successful results in high-capacity facilities.

-

Apron FeedersApron Feeder is a conveyor manufactured from steel plates driven by steel chains wearing on steel surfaces. They are a robust design manufactured for durability...Get Quote

Apron FeedersApron Feeder is a conveyor manufactured from steel plates driven by steel chains wearing on steel surfaces. They are a robust design manufactured for durability...Get Quote -

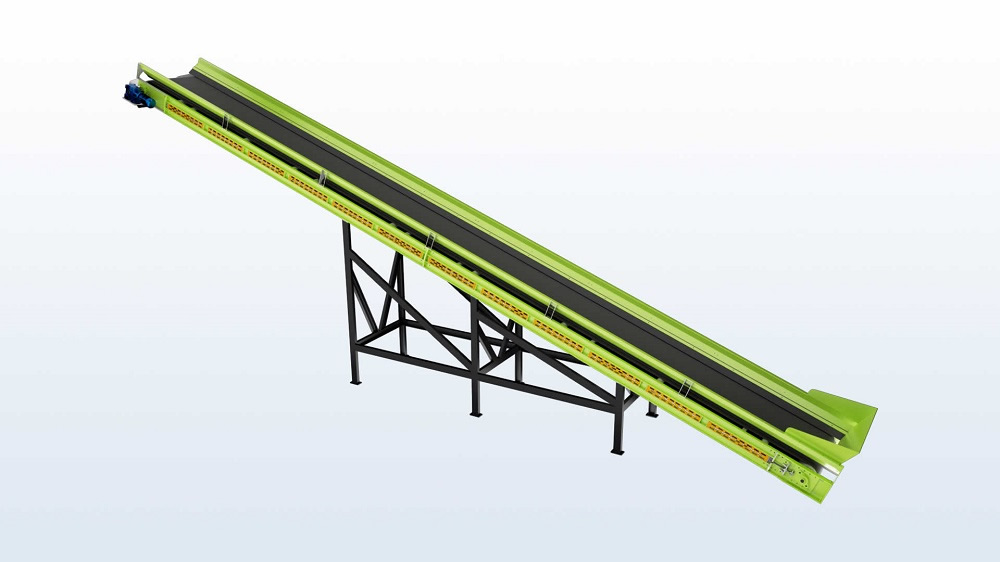

Conveyor BeltGarbage conveyor/Trash conveyor belt system is a processing line to classify paper, plastic, metal, glass, and organic matter and realize the recycling of rubb...Get Quote

Conveyor BeltGarbage conveyor/Trash conveyor belt system is a processing line to classify paper, plastic, metal, glass, and organic matter and realize the recycling of rubb...Get Quote -

Wobbler FeederWobbler feeder is a type of feeding equipment that uses rotating elliptical bars, known as wobblers, to separate materials based on size and type before they re...Get Quote

Wobbler FeederWobbler feeder is a type of feeding equipment that uses rotating elliptical bars, known as wobblers, to separate materials based on size and type before they re...Get Quote -

Waste FeederWaste feeder was specially designed to optimize municipal solid waste sorting systems. The Drum Feeder ensures that your sorting system, baler or shredder has a...Get Quote

Waste FeederWaste feeder was specially designed to optimize municipal solid waste sorting systems. The Drum Feeder ensures that your sorting system, baler or shredder has a...Get Quote