Waste Baler For MSW

-

Production Capacity:

8000-15000kg/h

-

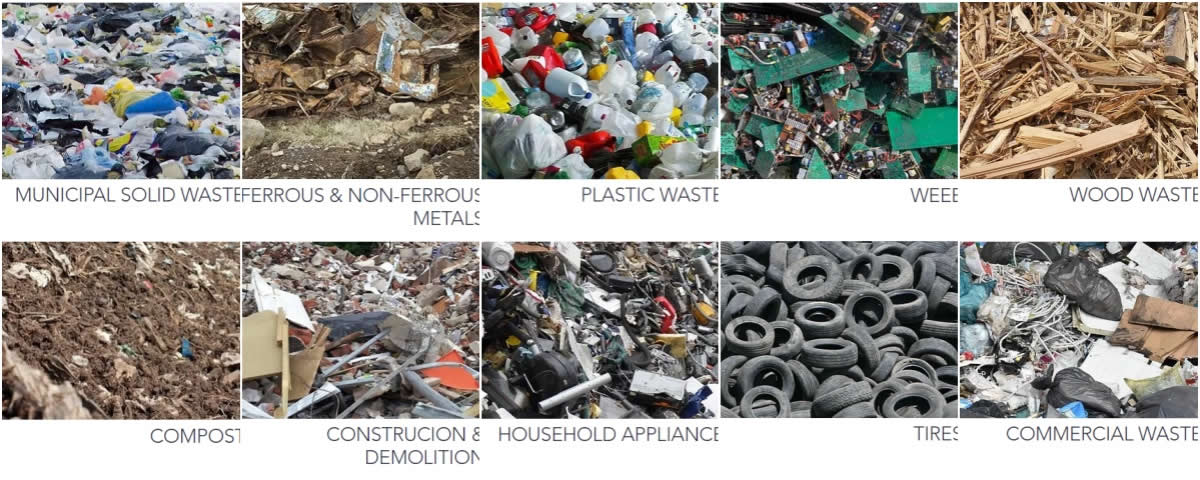

Applicable Industries:

including paper,cardboard, film, PP bulk bags, cans, PET bottles, drums, kegs or electronic scrap.

-

Power:

5.5kw-50kw

-

Core Components:

PLC /CE /ISO9001

-

Place of Origin:

Henan, China

- Product Details

- Characteristics

- Working Principle and Application

- Parameters

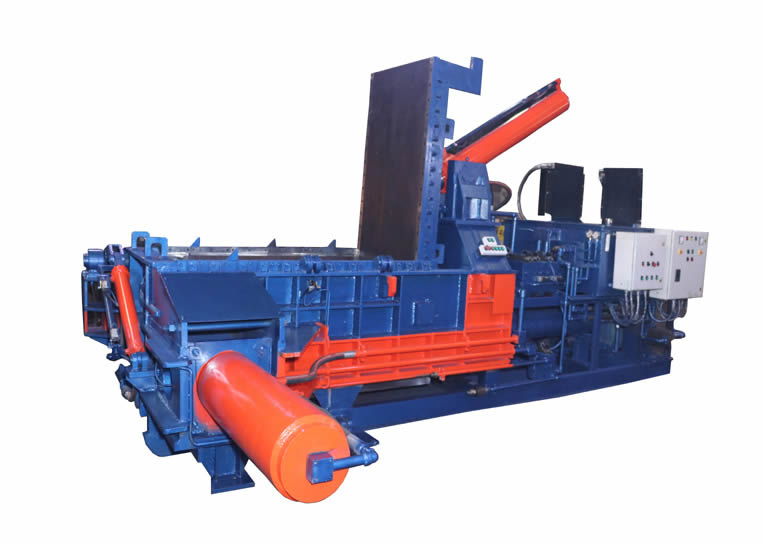

Waste Balers for MSW

Introduction to Waste Baling Presses

Zhongcheng has been at the forefront of developing waste baling presses for more than 15 years, specializing in both urban solid waste (MSW) and industrial solid waste. Our expertise and innovative designs have proven successful in compressing all types of solid waste, effectively reducing transportation costs and minimizing landfill space requirements.

Advantages of Zhongcheng Balers for MSW

High Density Baling Press

High density baling presses are essential in the final step before waste is sent to landfills. They are specifically designed and manufactured to handle the challenging task of compressing and baling various residues, thus extending landfill life and lowering the operational costs of final disposal.

MSW Hydraulic Packaging Machine

Our MSW hydraulic packaging machine is a high-efficiency compressed packaging equipment tailored for loose materials such as waste paper, plastic, straw, cotton, and wool. Utilizing advanced hydraulic technology, it offers high pressure, low noise, and simple operation. The unique dual compressed room design enhances the compression effect, significantly improving work efficiency. Additionally, its compact body design ensures it occupies a small area, making it convenient for moving and storage. This machine not only saves space and reduces transportation costs but also contributes to environmental protection, making it an ideal choice for sustainable waste management.

Robust Design and Efficiency

Zhongcheng's baling presses are constructed from sturdy electro-welded structures capable of withstanding continuous stress. They are characterized by great efficiency and performance along with very low fuel consumption. Our presses are designed for intensive use, with high-quality components that drastically reduce the need for maintenance. The use of special steels guarantees particularly long life cycles, leading to substantial savings on spare parts.

-

01Adopt advanced hydraulic driving, which has the characteristics of efficient energy and energy saving.

-

02Equipment work pressure, low noise, and easy operation can achieve a smooth operation experience.

-

03With a unique dual compressing room design, the compression effect is better and greatly improves work efficiency.

-

04Can customize the volume, packaging size, maximum working pressure and motor capacity according to the requirements.

Comprehensive Range of Industrial Presses

We offer a wide range of industrial presses, all designed and manufactured in our plants, to cater to various applications:

·Waste Compactors

·Presses for Plastic

·Presses for Paper

·Presses for Containers for Liquids

·Presses for PET Bottles

·Presses for Solid Urban Waste

·Presses for Special Materials

Waste Compactors

Our waste compactors are engineered to handle a wide variety of waste types, significantly reducing volume and optimizing space. This makes them ideal for use in industries, municipalities, and commercial establishments looking to enhance their waste management practices.

Presses for Plastic

Our presses for plastic are designed to compress various types of plastic waste, including films, bottles, and packaging materials. This reduces the bulkiness of plastic waste, making it easier to transport and recycle, thereby contributing to the reduction of plastic pollution.

Presses for Paper

Our paper presses are tailored for compressing paper waste, such as cardboard, newsprint, and mixed paper. By baling paper waste, we facilitate its recycling and repurposing, supporting sustainable practices in the paper industry.

Presses for Containers for Liquids

These presses are specialized for compacting liquid containers, such as plastic and metal bottles. By reducing the volume of these containers, we minimize the space they occupy in landfills and streamline their recycling process.

Presses for PET Bottles

PET bottle presses are specifically designed to handle the compression of PET plastic bottles. This reduces their volume significantly, making them easier to transport and recycle, thereby promoting the circular economy in the plastic industry.

Presses for Solid Urban Waste

Our presses for solid urban waste are built to manage the diverse and often challenging nature of municipal solid waste. They ensure efficient compression, leading to reduced landfill space usage and lower transportation costs.

Presses for Special Materials

We also provide presses designed for special materials that require unique handling and compression techniques. These include materials with specific recycling or disposal requirements, ensuring that all types of waste are managed effectively.

Sustainability and Environmental Protection

At Zhongcheng, we prioritize sustainability and environmental protection in all our operations. Our baling presses and compactors are designed to reduce the environmental impact of waste management. By compressing waste efficiently, we reduce the volume of waste that needs to be transported and disposed of, thereby lowering greenhouse gas emissions associated with these processes.

Reduction of Transportation Costs

The high density compression provided by our balers significantly reduces the volume of waste, leading to fewer trips needed for waste transportation. This reduction in transport frequency directly translates to lower fuel consumption and decreased operational costs.

Minimization of Landfill Space

By compressing waste into dense bales, our presses help minimize the space required in landfills. This not only extends the operational life of existing landfills but also reduces the need for new landfill sites, preserving natural landscapes and ecosystems.

Environmental Compliance

Our equipment is designed to comply with stringent environmental regulations and standards. We ensure that all our products meet or exceed industry requirements, promoting best practices in waste management and environmental stewardship.

Item | Name | parameter |

mainframe parameter | Bale size | 1100mm(W)×1100mm(H)×~1600mm(L) |

| Material type | Scrap Kraft paper, Newspaper, Cardboard ,Soft Film, | |

| Material density | 600~700Kg/m3(Mositure12-18%) | |

| Feed opening size | 2400mm×1100mm | |

| Main motor power | 45KW+15kw | |

| Main cylinder | YG280/210-2900 | |

| Capacity | 12-15 ton /hour | |

| Main cylinder force | 160T | |

| Max. system working force | 30.5MPa | |

| Mainframe weight(T) | About 25 tons | |

| Oil tank | 2m3 | |

| Mainframe size | About 11×4.3×5.8M(L×W×H) | |

| Tie wire line | 4 line φ3.0~φ3.2mm3 iron wire | |

| Pressure time | ≤30S/ (go and back for empty load) | |

Chain conveyor technology | Model | ZC-IV |

| Conveyor weight | About 7 tons | |

| Conveyor size | 2000*14000MM | |

| Conveyor motor | 7.5KW | |

Cool tower | Cool tower motor | 0.75KW(water Pump)+0.25(Fan) |

-

Waste Baler For MSWHigh density solid waste balers are the final step before sending waste to landfill. Horizontal balers designed and manufactured for this difficult job and prov...Get Quote

Waste Baler For MSWHigh density solid waste balers are the final step before sending waste to landfill. Horizontal balers designed and manufactured for this difficult job and prov...Get Quote -

Metal BalerMetal baler, specifically a hydraulic metal baler, is a machine designed to compress scrap metal into dense, manageable bales. This equipment is widely used in ...Get Quote

Metal BalerMetal baler, specifically a hydraulic metal baler, is a machine designed to compress scrap metal into dense, manageable bales. This equipment is widely used in ...Get Quote -

RDF Making MachineRDF (Refuse Derived Fuel) making machine is a specialized equipment used in waste management and energy recovery processes. Its primary function is to convert v...Get Quote

RDF Making MachineRDF (Refuse Derived Fuel) making machine is a specialized equipment used in waste management and energy recovery processes. Its primary function is to convert v...Get Quote -

Horizontal Semi-Auto Hydraulic BalerSemi automatic balers are used across the logistics, recycling and manufacturing sectors to process large volumes of waste materials such as cardboard, film, pa...Get Quote

Horizontal Semi-Auto Hydraulic BalerSemi automatic balers are used across the logistics, recycling and manufacturing sectors to process large volumes of waste materials such as cardboard, film, pa...Get Quote