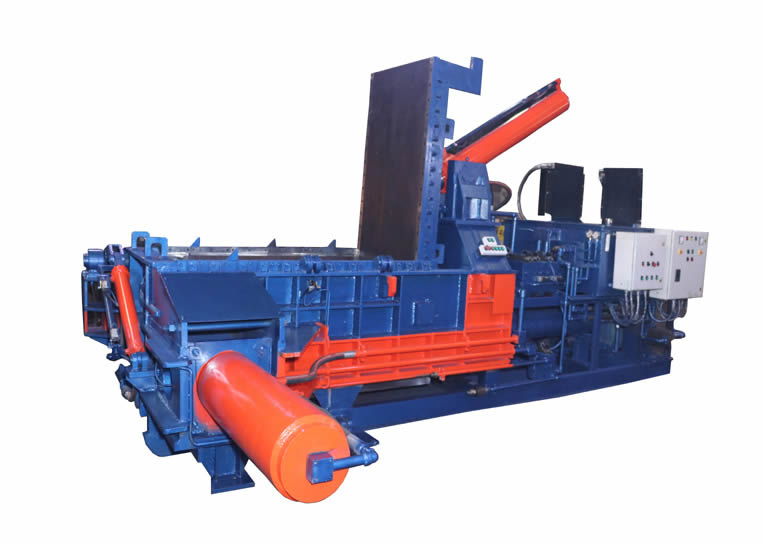

Metal Baler

-

Production Capacity:

25Mpa

-

Applicable Industries:

Metal

-

Power:

18.5KW -44kw

-

Core Components:

Sieve plate、PLC

-

Place of Origin:

Henan, China

- Product Details

- Characteristics

- Working Principle and Application

- Parameters

WHAT ARE METAL BALERS?

Metal balers are machines that crush, cut and compress scrap metal into manageable bales that are easier to transport than loose scrap. Balers were first developed for agricultural applications to eliminate manual raking and bundling of haystacks. However, the concept of baling has since been applied to many materials and applications, predominantly to speed up processes, reduce the volume of bulky materials and save on storage and transportation costs. There are many types of baler available, and they can be used to bale a wide range of recyclable materials, including paper, plastics and foam, and of course, scrap metal.

Industrial balers are used to improve scrap metal handling, compressing metal into a dense, manageable bale that is easily stackable for better storage. Scrap metal balers are often far more rugged than their plastic or paper counterparts since they need to compress and process tough metal effectively. In addition, many scrap metal baler models are capable of not only baling the metal but also cutting and crushing.

TYPES OF BALER

There are many different types of baler, and the kind of material you need to bale will dictate the style of machine required. For example, for ferrous metal processing, a ferrous baler is required. These balers can handle heavy materials and are some of the toughest balers around.

Ferrous metal balers use either two or three compression rams. In a two-compression model, one side (or wing door) squeezes the metal to crush it along with the main ram. In a three-compression model, both sides (or wing doors) squeeze the metal along with the main ram – or one side, a top lid and the main ram. All the rams are hydraulically operated, and material is fed into the baler either using a magnet or crane.

Metal balers can be portable or stationary. Stationary balers are suitable for applications in which the metal that needs baling is already at the site of the baler. However, since the point of metal balers is to compress and make the scrap metal easier to transport, it is often more beneficial to bring the baler to the site where metal is, rather than vice versa.

Non-ferrous metal processing can also take advantage of metal balers. A fantastic example of a non-ferrous metal that benefits immensely from baling is aluminium, a lightweight metal that can take up a lot of space before being compressed

-

01The baler delivery methods are optional include turn over, push forward, push side

-

02Suitable for baling scrap steel, scrap aluminum, iron, cans, stainless steel and other metals

-

03Can be equipped with diesel engine as power

-

04Hydraulic drive, optional manual operation or PLC automatic control

Ferrous metal balers use either two or three compression rams. In a two-compression model, one side (or wing door) squeezes the metal to crush it along with the main ram. In a three-compression model, both sides (or wing doors) squeeze the metal along with the main ram – or one side, a top lid and the main ram. All the rams are hydraulically operated, and material is fed into the baler either using a magnet or crane.

| MBQ125 | MBQ160 | MBQ200 | MBF125 | MBF160 | MBF200 | |

| Pressure | 25Mpa | 25Mpa | 25Mpa | 25Mpa | 25Mpa | 25Mpa |

| Power | 18.5KW | 22KW | 44KW | 18.5KW | 22KW | 44KW |

| Input size | 1550x600mm | 1600x950mm | 1400x700mm | 1010x800mm | 1500x900mm | 1600x1200mm |

| Output size | 600x300mm | 950x300mm | 700x280mm | 280x280mm | 400x400mm | 450x450mm |

| Outlet style | push | push | push | turn over | turn over | turn over |

-

RDF Making MachineRDF (Refuse Derived Fuel) making machine is a specialized equipment used in waste management and energy recovery processes. Its primary function is to convert v...Get Quote

RDF Making MachineRDF (Refuse Derived Fuel) making machine is a specialized equipment used in waste management and energy recovery processes. Its primary function is to convert v...Get Quote -

Metal BalerMetal baler, specifically a hydraulic metal baler, is a machine designed to compress scrap metal into dense, manageable bales. This equipment is widely used in ...Get Quote

Metal BalerMetal baler, specifically a hydraulic metal baler, is a machine designed to compress scrap metal into dense, manageable bales. This equipment is widely used in ...Get Quote -

Horizontal Semi-Auto Hydraulic BalerSemi automatic balers are used across the logistics, recycling and manufacturing sectors to process large volumes of waste materials such as cardboard, film, pa...Get Quote

Horizontal Semi-Auto Hydraulic BalerSemi automatic balers are used across the logistics, recycling and manufacturing sectors to process large volumes of waste materials such as cardboard, film, pa...Get Quote -

Waste Baler For MSWHigh density solid waste balers are the final step before sending waste to landfill. Horizontal balers designed and manufactured for this difficult job and prov...Get Quote

Waste Baler For MSWHigh density solid waste balers are the final step before sending waste to landfill. Horizontal balers designed and manufactured for this difficult job and prov...Get Quote