Jaw Crusher

-

Production Capacity:

10-600t/h

-

Applicable Industries:

aggregate production, construction material recycling, and mining operations.

-

Power:

5.5-220kw

-

Core Components:

eccentric shaft with heavy-duty double roll spherical roller bearings.

-

Place of Origin:

Henan, China

- Product Details

- Characteristics

- Working Principle and Application

- Parameters

stone jaw crusher,rock jaw crusher,concrete jaw crusher,mining jaw crusher,quarray jaw crusher

High-Quality Jaw Crusher : Boost Your Efficiency and Productivity

We are proud to introduce our high-efficiency jaw crushers, designed to meet the needs of various industries including mining, construction, and recycling. Our jaw crushers are engineered to deliver high performance, long-lasting durability, and versatility, making them the perfect solution for crushing hard and abrasive materials.

Jaw crusher has many advantages such as a large crushing ratio, simple structure, durability, adjustable discharge, deep crushing cavity, energy saving and environmental protection, etc. Therefore, it has been widely used in fields such as aggregate production, construction material recycling, and mining operations.

The jaw crusher is mainly used for primary crushing, and the broken stones are relatively large. Impact crushers, cone crushers, etc. are used to crush medium-sized stones and are mostly used for secondary crushing.

Why Choose Our Jaw Crushers?

Superior Engineering and Design

Our jaw crushers stand out due to their robust design and superior engineering. We utilize advanced manufacturing techniques, including laser cutting and bending to ensure precision in every component. This meticulous approach guarantees that our jaw crushers operate smoothly and efficiently, providing maximum output with minimal downtime.

High-Quality Materials

We only use high-grade materials in the construction of our jaw crushers. The frame is built from heavy-duty steel to withstand the rigors of continuous use, while the jaws are crafted from high-strength manganese alloy to resist wear and tear. This combination ensures that our jaw crushers are both durable and reliable.

Innovative Features for Enhanced Performance

1. Adjustable Crushing Settings

Our jaw crushers come with adjustable crushing settings, allowing you to tailor the machine to your specific needs. Whether you need a finer or coarser output, our jaw crushers can be easily adjusted to meet your requirements, ensuring optimal performance for every application.

2. Efficient Lubrication System

To reduce maintenance and extend the lifespan of our jaw crushers, we have integrated an efficient lubrication system. This system ensures that all moving parts are adequately lubricated, reducing friction and wear, and allowing the machine to run smoothly for longer periods.

3. Advanced Safety Features

Safety is a top priority in the design of our jaw crushers. We have incorporated several advanced safety features, including emergency stop buttons and protective covers for moving parts, to ensure the safety of operators and maintenance personnel.

Customer Satisfaction and High Evaluations

We have received high evaluations from our customers who have experienced the performance and reliability of our jaw crushers. Our commitment to quality and customer satisfaction has earned us a reputation as a trusted manufacturer in the industry.

Positive Feedback from Our Customers

John D., USA

· "The jaw crusher we purchased from zhongcheng company has significantly improved our production efficiency. The delivery was fast, and the installation process was smooth and hassle-free. The machine operates perfectly, and we are very satisfied with the after-sales support provided."

Ahmed K., UAE

· "Our experience with this jaw crusher has been fantastic. It was delivered on time and installed without any issues. The machine's performance is top-notch, and the after-sales support has been outstanding. We are very happy with our purchase."

Emma R., Australia

· "This jaw crusher has exceeded our expectations in every way. The build quality is excellent, and it operates smoothly. The delivery was fast, and the installation team did a great job. The after-sales service has been very supportive and responsive."

Carlos M., Brazil

· "We are very satisfied with our jaw crusher purchase. The machine was delivered quickly, and the installation process was seamless. It performs exceptionally well, and the after-sales support has been superb. Great value for money."

-

01Large crushing ratio and uniform product particle size: The jaw crusher has a high crushing ratio, which means it can effectively break large pieces of materials into smaller particle sizes. At the same time, by adjusting the parameters of the equipment, uniform product particle size can be obtained to meet different production needs.

-

02Simple structure and stable operation: The structure of the jaw crusher is relatively simple, which makes it more convenient to operate and maintain. The bearings, moving cone, and other parts of the jaw crusher have been optimized and designed to withstand greater impact and wear, extending the service life of the equipment.

-

03Adjustable discharge, more flexible: Jaw crushers are usually equipped with a discharge port adjustment device, which can easily adjust the discharge particle size. This enables it to adapt to materials of different specifications and hardness, improving the adaptability and flexibility of the equipment.

-

04Deep crushing cavity and high efficiency: The crushing cavity of the jaw crusher is designed to be deep and there is no dead space, which helps to increase the feeding capacity and output. At the same time, the crushing efficiency of the equipment has also been improved, saving energy consumption and production costs.

The working principle of jaw crusher

Although the jaw crusher has various structural types, its working principle is the same, that is, the material is crushed by the periodic motion of the movable jaw. In the process of swinging the movable jaw to the fixed jaw around the suspension mandrel, the material between the two jaw plates is subjected to the combined action of crushing, splitting and bending. At the beginning, the pressure is small, so that the volume of the material is reduced, and the materials are close to each other and squeezed tightly; when the pressure rises beyond the

strength that the material can bear, it will break. On the contrary, when the movable jaw leaves the fixed jaw and swings in the opposite direction of the car, the material moves downward by its own weight. Each periodic movement of the movable jaw causes the material to be crushed once and sent down a certain distance. After several cycles, the crushed materials are discharged from the discharge port.

Applications of Our Jaw Crushers

Mining Industry

In the mining industry, our jaw crushers are used for crushing various types of ore, including gold, copper, and iron. Their robust construction and high capacity make them ideal for processing large volumes of material efficiently.

Construction Industry

Our jaw crushers are widely used in the construction industry for crushing concrete, asphalt, and other building materials. They provide a cost-effective solution for reducing material size and preparing it for further processing or disposal.

Recycling Industry

In the recycling industry, our jaw crushers play a crucial role in reducing the size of recyclable materials such as glass, metal, and plastic. This not only helps in efficient recycling but also reduces waste and promotes environmental sustainability.

Easy Assembly and Overseas Delivery

Quick Assembly

Our jaw crushers are designed for quick and easy assembly. With laser drilling and high-strength bolt splicing, the entire machine can be assembled rapidly, reducing downtime and getting you up and running faster.

Convenient Overseas Delivery

We understand the challenges of international shipping, which is why our jaw crushers are designed to be convenient for overseas delivery. Each unit is carefully packaged to ensure it arrives in perfect condition, ready for immediate use.

If you are interested in learning more about our jaw crushers or would like to place an order, please contact us today. Our team of experts is ready to assist you with all your crushing needs.

| Model | Feeding port size (mm) | Max feeing Size(mm) | Discharging size(mm) | Capacity (t/h) | Power (kw) | Weight (t) | Size (mm) |

| PE250×400 | 400×250 | 200 | 20-50 | 5-20 | 15 | 3 | 1430×1310×1340 |

| PE400×600 | 400×600 | 350 | 40-100 | 15-60 | 30-37 | 7 | 1700×1732×1653 |

| PE500×750 | 500×750 | 425 | 50-100 | 40-110 | 45-55 | 12 | 2035×1921×2000 |

| PE600×900 | 600×900 | 480 | 65-160 | 90-180 | 55-75 | 17 | 2290×2206×2370 |

| PE750×1060 | 750×1060 | 630 | 80-140 | 110-320 | 90-110 | 29 | 2655×2302×3110 |

| PE900×1200 | 900×1200 | 750 | 95-165 | 220-450 | 110-132 | 58 | 3800×3166×3045 |

| PE1000×1200 | 1000×1200 | 850 | 200-300 | 280-560 | 110-160 | 69 | 5350×4280×3050 |

| PE1200×1500 | 1200×1500 | 1020 | 150-300 | 400-800 | 160-220 | 100.9 | 6380×5310×3710 |

| PE1500×1800 | 1500×1800 | 1200 | 210-360 | 520-1100 | 280 | 132 | 7460×6235×4249 |

| PEX150×250 | 150×250 | 125 | 10-40 | 1-3 | 5.5 | 1.5 | 896×745×935 |

| PEX150×750 | 150×750 | 125 | 18-48 | 5-16 | 15 | 3.8 | 1200×1500×1200 |

| PEX250×750 | 250×750 | 210 | 25-60 | 15-30 | 22-30 | 5 | 1667×1545×1020 |

| PEX250×1000 | 250×1000 | 210 | 25-60 | 15-50 | 30-37 | 7 | 1550×1964×1380 |

| PEX250×1200 | 250×1200 | 210 | 25-60 | 20-60 | 37-45 | 8.5 | 2192×1900×1950 |

| PEX300×1300 | 300×1300 | 250 | 20-90 | 30-90 | 55-75 | 11.5 | 1750×2320×1724 |

-

Hydraulic Cone CrusherHydraulic Cone Crusher integrates machinery, hydraulic pressure, electrics, automation, and intelligent control, which can be used for medium crushing, fine cru...Get Quote

Hydraulic Cone CrusherHydraulic Cone Crusher integrates machinery, hydraulic pressure, electrics, automation, and intelligent control, which can be used for medium crushing, fine cru...Get Quote -

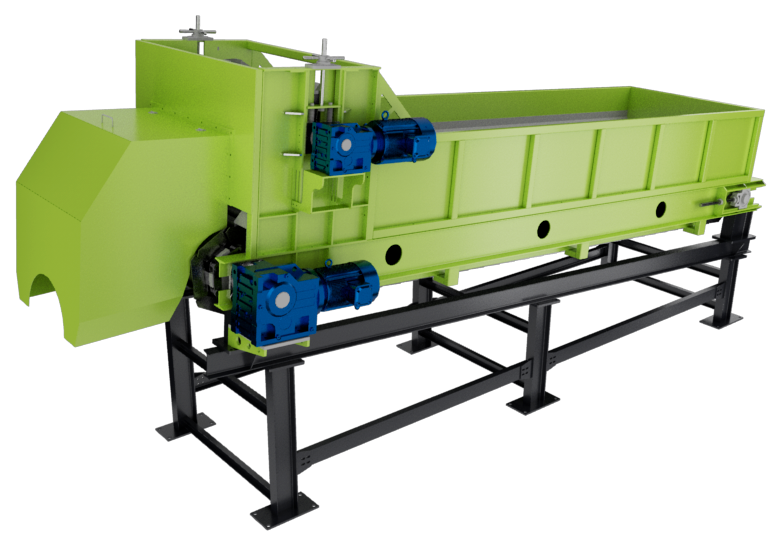

Double-Shaft ShredderThe Double-shaft shredder is a widely used industrial shredder that efficiently processes various mixed waste materials, such as construction waste, industrial ...Get Quote

Double-Shaft ShredderThe Double-shaft shredder is a widely used industrial shredder that efficiently processes various mixed waste materials, such as construction waste, industrial ...Get Quote -

Mobile Impact Crusher PlantThe mobile impact crusher plant is a kind of crushing equipment based on a mobile platform. It uses an impact crusher as the host machine and is usually equippe...Get Quote

Mobile Impact Crusher PlantThe mobile impact crusher plant is a kind of crushing equipment based on a mobile platform. It uses an impact crusher as the host machine and is usually equippe...Get Quote -

Bag OpenerBag opener or bag opener system is a mechanical device used to automatically open and empty bags containing bulk materials. This system is commonly used in indu...Get Quote

Bag OpenerBag opener or bag opener system is a mechanical device used to automatically open and empty bags containing bulk materials. This system is commonly used in indu...Get Quote