Solid waste recycling plant

-

Production Capacity:

30t/h-120t/h

-

Applicable Industries:

Garbage sorting、Commercial recycling

-

Power:

-

Core Components:

bag opener、trommel screens、air separator

-

Place of Origin:

Henan, China

- Product Details

- Characteristics

- Working Principle and Application

- Parameters

solid WASTE RECYCLING plant --------- Waste sorting: solutions for diverse requirements

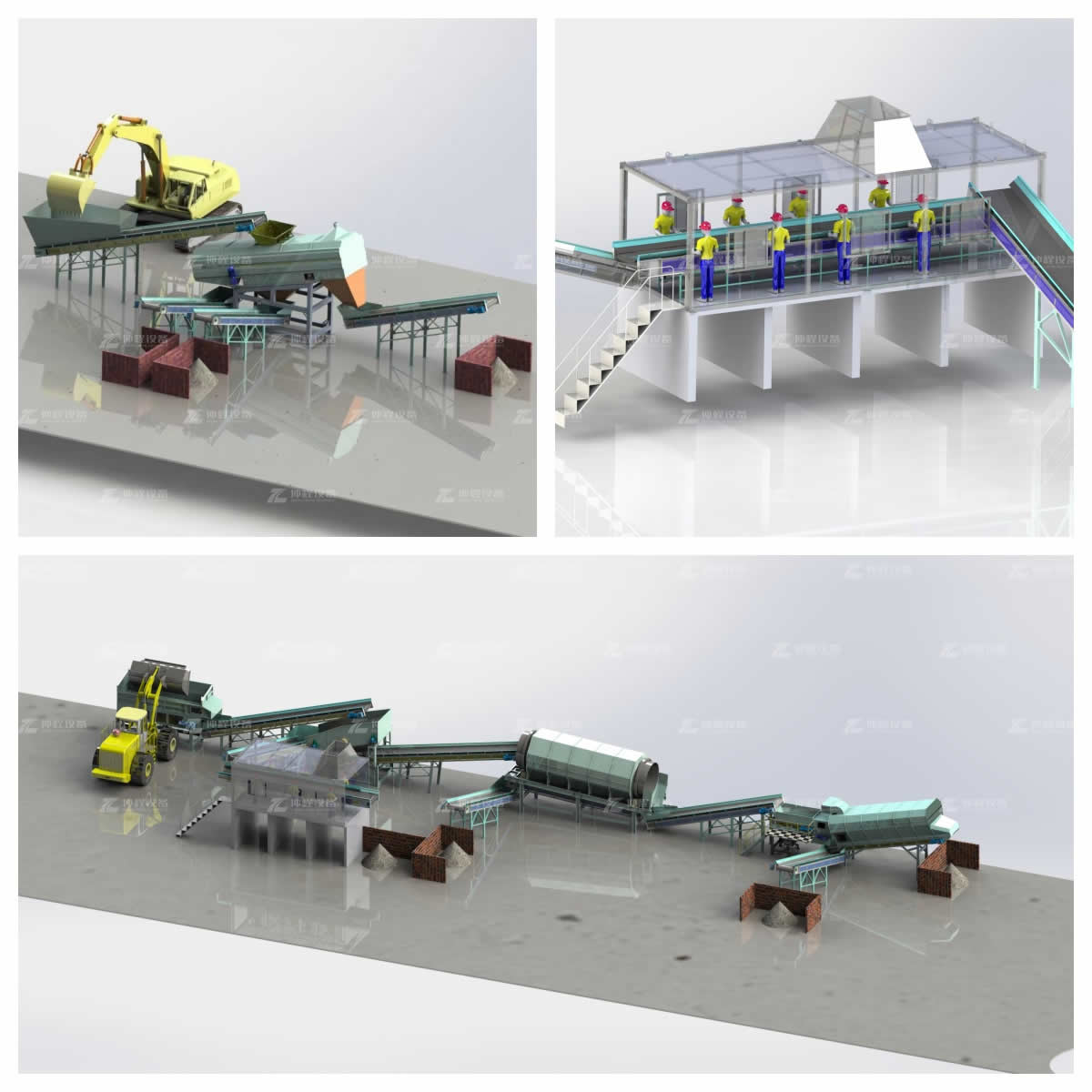

The main common disposal methods for municipal waste are landfill, composting and incineration, but all must be shredded and refined before disposal. Zch offers a full range of MSW disposal systems to help improve treatment efficiency and recycling rates through pre-shredding, magnetic separation, screening and fine shredding processes to reduce the volume of MSW and sort them.

As a company focused on waste management and recycling, Zch has a wide range of businesses aimed at promoting sustainable development and environmental protection. The following are the areas of mixed waste sorting equipment business covered by Zch。

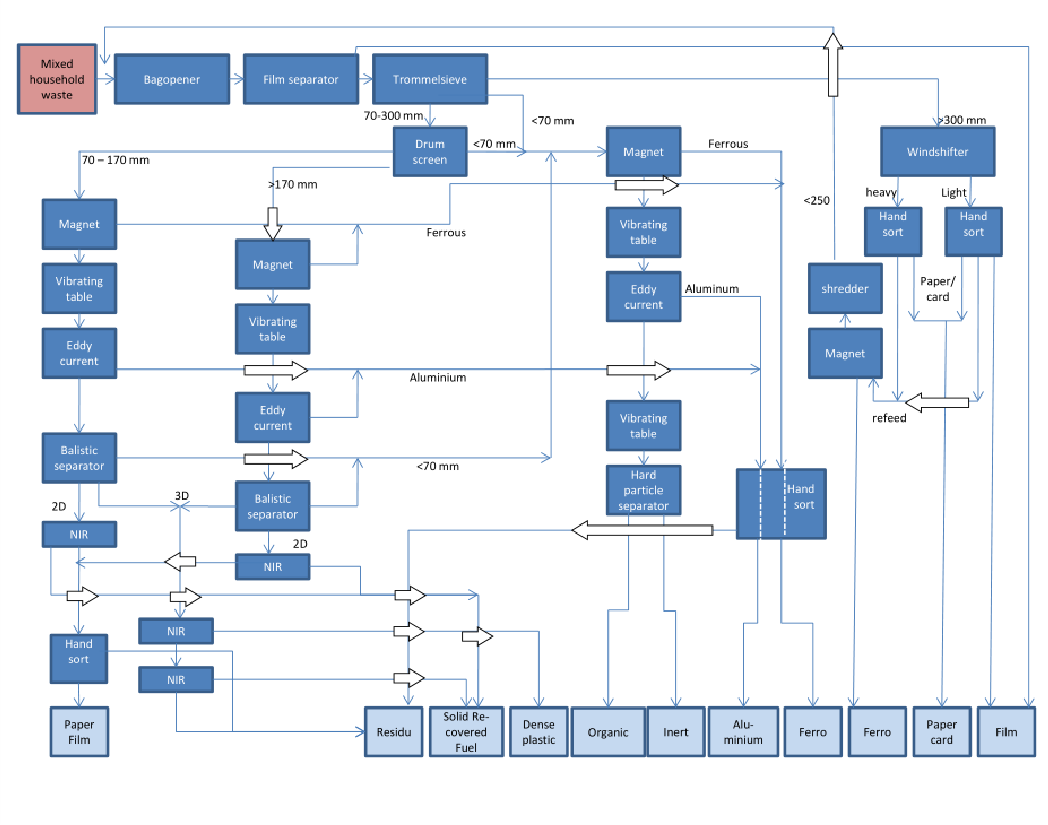

Example process description for an automated sorting plant for municipal solid waste with manual re-sorting:

After infeed dosing, the material is separated into different grain sizes according to shape (flat [2D], rolling [3D], screening) by various screening processes via our trommel screen and ballistic separator machinery. In order to achieve the maximum possible sorting purity, large-area films are separated from the material flows with the aid of windshifters. This significantly improves subsequent sorting using near infrared technology (NIR). In combination with the subsequent magnetic and eddy current process, the desired high output qualities are achieved. Following manual quality controlling, the material is finally separated into fractions, collected in hopper belts and pressed to reduce volume for storage and transport.

At Zch we believe that every piece of waste is an opportunity waiting to be unlocked. Our mission is simple yet profound: to harness the power of technology to sort, recycle, and repurpose waste materials efficiently and sustainably. At the forefront of our operations stands the marvel of modern engineering – Solid Waste Sorting Plant, a sophisticated system designed to streamline the sorting process, making it faster, more accurate, and environmentally friendly.

Delivering the high throughput and recovery rates demanded by today’s waste industry requires innovation, experience, and engineering excellence. Our patented MSW sorting process separates us from the competition as clearly as it separates commodities from the waste stream. This innovation will take your business to a whole new level of profitability

Our machines are especially designed for the needs of paper mills, corrugated cardboard factories, paper converting factories, hypermarkets, large and small recovery, landfills, reference stations, manufacturing plants, RDF systems, biostabilisation etc.

-

01The entire system is intelligently controlled, easy to operate, high in processing efficiency, low in energy consumption, and saves manpower and operating costs.

-

02The system is closed and equipped with environmental protection equipment, which meets environmental protection standards and has no secondary pollution.

-

03Wide range of waste disposal, good classification effect of different substances.

-

04custom design,high diversion rates,option to remove organics,durable and low maintenance

Waste processing machine

Key equipment in waste sorting lines:

Bag openers are specialized pieces of machinery designed to efficiently open and empty bags containing mixed waste materials. These devices automate the process of opening sealed bags, which is common in municipal solid waste (MSW) and commercial waste streams. Bag openers use sharp blades or teeth to cut open bags, ensuring that the contents are fully exposed for subsequent sorting processes. This step is crucial because it allows optical sorters and other sorting equipment to access and process the contents uniformly, enhancing the overall efficiency of the sorting line.

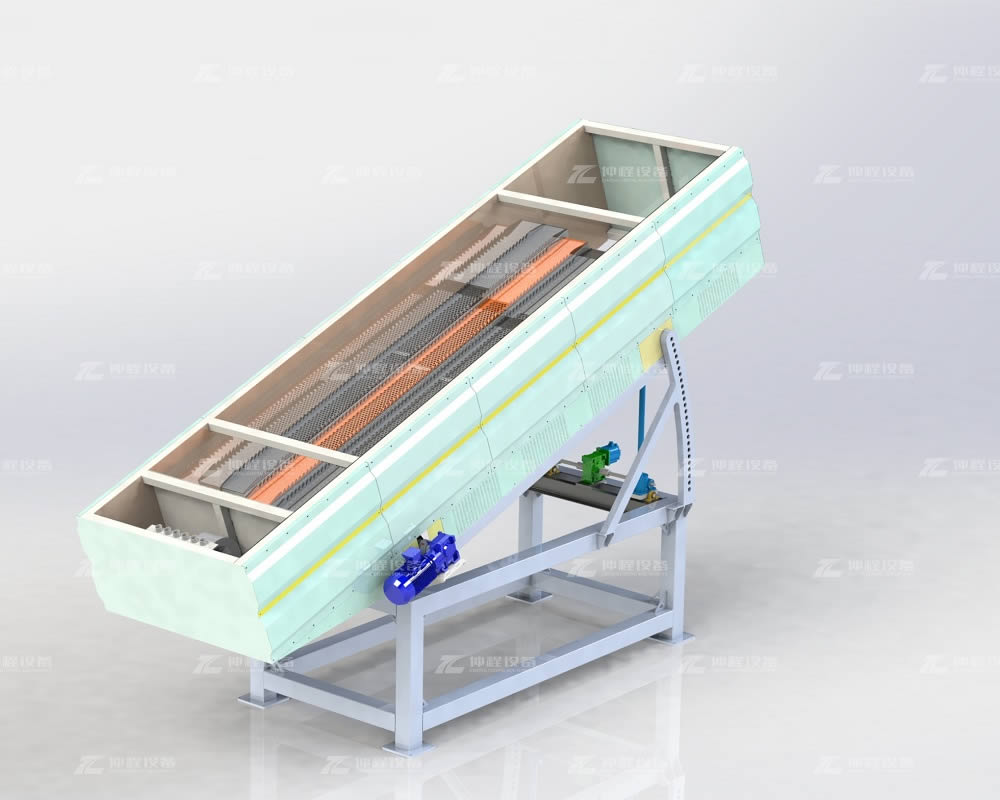

2. Drum Screens (Roller /trommel Screens)

Drum screens, also known as roller screens, are cylindrical-shaped sieves that play a critical role in the initial stages of waste sorting. They are designed to separate waste into different sizes, typically allowing smaller particles to pass through while retaining larger objects. The rotating action of the drum helps to agitate the waste, improving the separation efficiency.

which transports waste from one point to another within the facility. These belts can be equipped with sensors and cameras that help identify different types of waste, ensuring that the material reaches the correct sorting station.

4.Optical Sorters

Optical sorters use high-resolution cameras and sophisticated software to distinguish between various types of waste based on color, shape, size, and even chemical composition. Once identified, the waste is sorted into categories such as plastics, paper, metals, and organic waste.

5. Near-Infrared (NIR) Technology

Near-infrared technology is particularly useful for sorting materials like plastics and paper. NIR scanners emit light that is absorbed differently by various materials. By analyzing the reflected light, the system can accurately determine the type of plastic or paper and direct it to the appropriate bin.

6. Magnetic Separators

Magnetic separators are essential for removing ferrous metals from the waste stream. These devices use powerful magnets to attract and collect metallic items, which are then separated from other materials.

7. Eddy Current Separators

For non-ferrous metals like aluminum and copper, eddy current separators are employed. These machines create a magnetic field that repels non-iron-based metals, effectively separating them from the rest of the waste.

Air drum seperator use air currents to separate lightweight materials from heavier ones. This method is commonly used to sort paper and plastic films from heavier items like glass bottles and cans.

9. Robotic Sorters

Robotic sorters have been gaining popularity due to their precision and speed. Equipped with artificial intelligence (AI), these robots can learn and adapt to new sorting criteria, making them highly efficient at sorting complex mixtures of waste.

10. Composting Systems

For organic waste, composting systems are utilized to transform biodegradable materials into nutrient-rich compost. These systems can range from simple outdoor piles to more complex aerated static pile systems or in-vessel composting units.

11. Baling Presses

After sorting, baling presses are used to compress recyclable materials into compact bales. This process not only saves space but also makes transportation more economical.

High quality machines

The benchmark in the field of recycling and disposal of municipal solid waste, our machines are dedicated to :

recovery and waste sorting platforms

waste treatment plants

Waste tire recycling

transfer stations

landfills

| Main components | Output fractions |

| bag opener | Ferrous metal |

Heavy-duty infeed hopper | Film |

Shredder | Fine grain |

Trommel screen | Mixed plastic |

Ballistic separator | Non-ferrous metal |

Windshifter | Organic |

Near infrared technology NIR | Paper/cardboard/paperboard |

Eddy current separator | PET |

Second-stage shredder | PE |

Sorting cabin | PP |

Baler | |

Conveyor | |

Electrical engineering |

Our company engaged in waste sorting system . We are professional about waste sorting system . We have professional technical team. Professional technical team can provide customized project design.The professional and well skilled installation team enable the fast and high quality installation accomplished, from equipment install, electrical commissioning, to operator training, etc, to provide client with a one-stop service and support.OEM and ODM orders are acceptable for us. Welcome to contact us and talk your requirements with our Customer Service Center.

| Model | Length Range | Segment No. | Aperture Size | Power (Kw) | Inclined Angle | Max. Material Size | Rotating Speed(rpm) |

| ZCφ600 | 2-4m | 1-2 | ≤30mm | 2.2-3 | 0-7° | 60mm | 12-18 |

| ZCφ800 | 2-5m | 1-3 | ≤50mm | 3-5.5 | 0-7° | 100mm | 12-18 |

| ZCφ1000 | 2-6m | 1-4 | ≤100mm | 4-11 | 0-7° | 150mm | 10-18 |

| ZCφ1200 | 3-8m | 1-4 | ≤150mm | 5.5-18.5 | 0-7° | 200mm | 9-15 |

| ZCφ1500 | 3-10m | 1-5 | ≤200mm | 7.5-22 | 0-7° | 250mm | 9-15 |

| ZCφ1800 | 4-12m | 1-5 | ≤220mm | 7.5-22 | 0-7° | 270mm | 8-15 |

| ZCφ2000 | 5-15m | 1-5 | ≤250mm | 11-30 | 0-7° | 300mm | 8-12 |

| ZCφ2500 | 5-18m | 1-6 | ≤300mm | 11-30 | 0-7° | 350mm | 8-12 |

customized according to your requirements

-

Optimize Your Waste Management Today with Our Advanced Drum ScreensUnderstanding the Mechanism and Optimization of Drum Screens for Waste ManagementGet Quote

Optimize Your Waste Management Today with Our Advanced Drum ScreensUnderstanding the Mechanism and Optimization of Drum Screens for Waste ManagementGet Quote -

Solutions for Jaw Crusher ProblemsJaw crusher is widely used in mining, smelting, building materials, highways, railways, water conservancy and chemical industries. The maximum compressive stren...Get Quote

Solutions for Jaw Crusher ProblemsJaw crusher is widely used in mining, smelting, building materials, highways, railways, water conservancy and chemical industries. The maximum compressive stren...Get Quote -

Compact Copper Cable Granulator MachineThe compact copper cable granulator machine is a device used to recycle waste wires and cables. It separates the copper wire from the plastic sheath by crushing...Get Quote

Compact Copper Cable Granulator MachineThe compact copper cable granulator machine is a device used to recycle waste wires and cables. It separates the copper wire from the plastic sheath by crushing...Get Quote -

Can the Angle of the Ballistic Separator Be Adjusted?Ballistic separator is a type of mechanical sorting device used primarily in the recycling industry to separate materials based on their physical properties. It...Get Quote

Can the Angle of the Ballistic Separator Be Adjusted?Ballistic separator is a type of mechanical sorting device used primarily in the recycling industry to separate materials based on their physical properties. It...Get Quote