Can the Angle of the Ballistic Separator Be Adjusted?

-

Production Capacity:

30~150m³/h

-

Applicable Industries:

Recycling Plants/Waste Management/Composting Facilities/MSW

-

Power:

5.5-22kw

-

Core Components:

Crankshaft maintenance access. Centralised lubrication system.

-

Place of Origin:

Henan, China

- Product Details

- Characteristics

- Working Principle and Application

- Parameters

Can the Angle of the Ballistic Separator Be Adjusted?

Many customers who are interested in purchasing a ballistic separator often ask if the angle of the separator can be adjusted and how this adjustment is performed. Today, Sophia from Zhongcheng Company will address this concern.

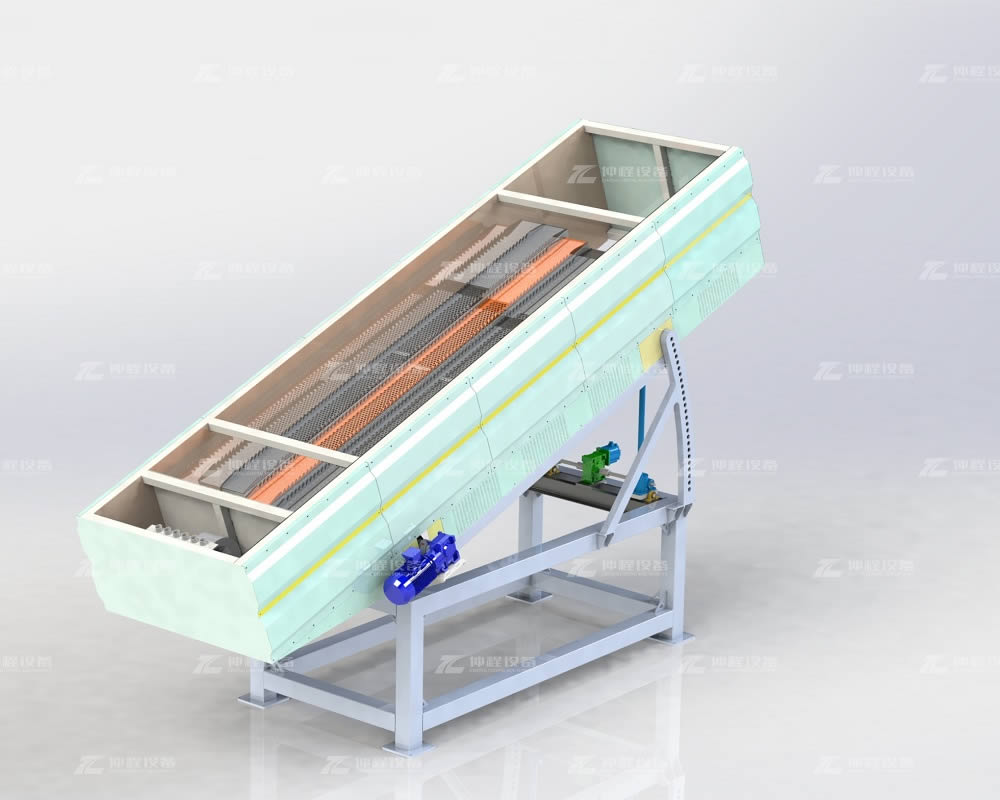

Ballistic separators are multifunctional machines which allow to process various types of waste: include light materials(plastic, paper, and small particles.) heavy materials construction and demolition ,as well as municipal solid waste(metal, glass and large objects). These machines are capable to divide material based on their motion track into three fractions – heavier 3D fractions (such as tins or stones), lighter 2D or flat fractions( such as paper and film),and small-sized fractions such as soil and aggregate).The paddles and sieve screens consist of wear-resistant steel. The lateral sheets at the paddles are additionally reinforced. Furthermore, the entire machine frame and the shafts are adapted to the increased requirements. All eccentric bearings are doubled,Eccentric Bearings can be replaced without removing the shaft,No high-maintenance crankshaft,Shock absorber for each paddle, Central lubrication pump system。

Can the Angle of the Ballistic Separator Be Adjusted?

Yes, the angle of a ballistic separator can indeed be adjusted. This feature is crucial for optimizing the separation process based on the characteristics of the materials being processed. Adjusting the angle allows the machine to better handle various types of waste and improve overall separation efficiency.

How to Adjust the Angle of the Ballistic Separator?

Here’s a step-by-step guide on how to adjust the angle:

Ensure Safety: Before making any adjustments, make sure the machine is turned off and secured to prevent any accidents.

Locate the Adjustment Mechanism: Depending on the model of the ballistic separator, this could be a manual, hydraulic, or electric system.

Manual Adjustment: Look for bolts, screws, or levers that control the angle. These are typically found at the base or sides of the separator.

Hydraulic or Electric Adjustment: These systems are often controlled via a panel or remote control, allowing for easier adjustments.

Adjust the Angle:

Manual Systems: Loosen the bolts or screws to adjust the angle. Move the separator to the desired angle and then tighten the bolts or screws to secure the new position.

Hydraulic/Electric Systems: Use the control panel or remote to adjust the angle. These systems often have presets or digital readouts to help you set the exact angle needed.

Secure the New Angle: Ensure that all adjustment mechanisms are tightly secured after the angle is set. This will prevent any unintentional movement during operation.

Test the Separator: Turn the machine back on and run a test with the new angle setting. Observe the separation process to ensure it is functioning as desired.

Why Adjust the Angle?

Adjusting the angle is important because different materials require different angles for optimal separation:

Steeper Angles: Ideal for lighter and flatter materials, such as paper and plastics, allowing them to move quickly to the discharge end.

Shallower Angles: Better for heavier and more rigid materials, such as metals and glass, giving them more time to roll back and separate effectively.

By adjusting the angle, you can customize the ballistic separator to handle specific waste streams more efficiently, improving the quality of the separated materials and overall productivity.

I hope this explanation helps clarify the adjustability of the angle of a ballistic separator and how you can manage this feature to optimize your waste separation processes. If you have any more questions or need further assistance, feel free to reach out to us at Zhongcheng Company!

-

01Efficiency: Can process large volumes of material quickly.Effective in separating different types of materials with minimal manual intervention.

-

02Versatility: Effective for a wide range of materials.Can handle a variety of waste streams, including municipal solid waste, commercial waste, and recyclables.

-

03Automation: Can be integrated into automated sorting systems, reducing the need for manual sorting.

-

04Enhanced Recycling Rates: Improves the quality of recycled materials by providing a cleaner separation.

The types of waste that can be screened with the ballistic separator are numerous: lightweight packaging, paper/cardboard, foil and plastic containers, commercial and industrial waste (C&I), municipal solid waste (MSW), waste from construction and demolition (C&D)… Hence, the output flows of a ballistic separator are:

heavy and rolling fraction, 3D: flacons and plastic bottles (PET and polyethylene HD), cans, wood, stones…

flat and light fraction, 2D: envelopes, trays and plastic film (polyethylene LD), textiles, paper and cardboard…

sieved fraction: depending on the size of the holes of the grids on the screening paddles it possible to classify different sizes of underscreen fraction. This fraction, typically not recoverable, has dimensions approximately of 40-50 mm and it contains soil, sand, organic waste and small pieces of recyclables.

Ballistic separators ensure high purity, cleaner output and require little maintenance which results in low downtime.

| BS04 | BS06 | BS08 | BS10 | BS12 | |

| Paddy Number | 4 | 6 | 8 | 10 | 12 |

| Paddle length | 5.5m | 5.5m | 5.5m | 5.5m | 5.5m |

| Angle adjustment | 0 – 30° | 0 – 30° | 0 – 30° | 0 – 30° | 0 – 30° |

| Sieve hole size | 10-80 mm | 10-80 mm | 10-80 mm | 10-80 mm | 10-80 mm |

| Fan Number | 2 - 4 | 2 - 4 | 2 - 4 | 2 - 4 | 2 - 4 |

| Power | 5.5kw | 7.5kw | 11kw | 11kw | 22kw |

| Throughput | 0-30 m³/h | 30-50 m³/h | 50-70 m³/h | 70-90 m³/h | 90-120 m³/h |

-

Efficient Material Separation with Bounce ScreensThe ballistic separator is an important equipment with separation function designed for the sorting of inorganic particles in the coarsely crushed waste.Get Quote

Efficient Material Separation with Bounce ScreensThe ballistic separator is an important equipment with separation function designed for the sorting of inorganic particles in the coarsely crushed waste.Get Quote -

Waste Trommel And Copmost TrommelHowever, it's important to choose the right type of drum screen based on your specific needs. Today, Kevin from Zhongcheng Company will explain the differences...Get Quote

Waste Trommel And Copmost TrommelHowever, it's important to choose the right type of drum screen based on your specific needs. Today, Kevin from Zhongcheng Company will explain the differences...Get Quote -

Scrap rubber product shredderThe shredder of waste rubber products not only helps to reduce environmental pollution, but also improves the reuse rate of waste rubber, which is one of the im...Get Quote

Scrap rubber product shredderThe shredder of waste rubber products not only helps to reduce environmental pollution, but also improves the reuse rate of waste rubber, which is one of the im...Get Quote -

Crush to Create: The Ultimate Eco-Friendly Plastic Shredder RevolutionThe working principle of a plastic shredder is mainly to tear large plastic materials into small pieces or fragments through mechanical force, in order to facil...Get Quote

Crush to Create: The Ultimate Eco-Friendly Plastic Shredder RevolutionThe working principle of a plastic shredder is mainly to tear large plastic materials into small pieces or fragments through mechanical force, in order to facil...Get Quote