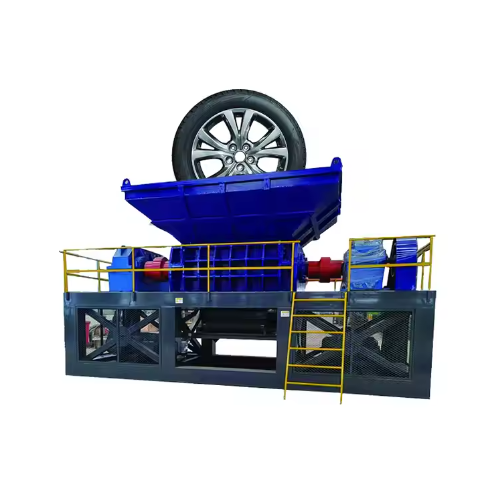

Scrap rubber product shredder

-

Production Capacity:

800-100000kg per hour

-

Applicable Industries:

Filler, Rubber particles, Fuel

-

Power:

30kw-220kw

-

Core Components:

Shaft, Blades, Motor, Reducer

-

Place of Origin:

Henan, China

- Product Details

- Characteristics

- Working Principle and Application

- Parameters

Main features

Efficient treatment: can quickly process a large number of waste rubber materials.

Strong adaptability: Suitable for many types of rubber products, including materials containing wire or other impurities.

Use precautions

Pretreatment: Before shredding, metal or other non-rubber components in rubber products should be removed as far as possible to avoid damaging the tool.

Size control: Select the appropriate screen aperture according to the end use to obtain the desired size of the torn product.

Maintenance: Check the tool wear condition regularly, and replace the tool with serious wear in time. At the same time, keep the shredding chamber clean to avoid dust accumulation or blockage.

-

01Rubber particles: can be used to manufacture recycled rubber products, such as rubber floor tiles, sports ground laying materials.

-

02Filler: can be used in road construction filling material, improve the damping performance of the road surface.

-

03Fuel: After proper treatment, it can be used as an alternative fuel for industrial furnaces such as cement kilns.

-

04Composite materials: composite with plastics, metals and other materials to make composite materials.

1. Main components

Feed port: Used for loading scrap rubber products to be torn.

Shredding chamber: The interior is equipped with two or more rotating shafts, on which a tool or knife teeth are installed to tear the rubber material by rotation. Hydraulic hose crimping machine play a pivotal role in ensuring the durability and reliability of hydraulic systems.

Tool: usually made of high hardness alloy steel, with good wear resistance and impact resistance.

Drive system: Provides power to the shredding shaft, usually consisting of an electric motor or hydraulic system.

Screen/grid: Control the size of the torn product, only the pieces that meet the size requirements can pass through.

Control system: including start/stop button, emergency stop button, overload protection and other safety functions.

Collection system: The shredded material passes through the screen and is collected into the designated container or transported on the conveyor belt.

2. How it works

Feed: the waste rubber products are sent to the shredder through the feed port.

Shredding: When the rubber material enters the shredding chamber, the knives on two or more rotating axes will tear it into smaller pieces.

Size control: The shredded rubber pieces pass through the bottom screen or grid, and the pieces that do not meet the size requirements will continue to be shredded in the chamber until the size requirements are met.

Collection: The rubber pieces that meet the size requirements are collected through the screen for further processing or direct use as recycled materials.

Good durability: made of high-strength material, it can run stably for a long time.

Easy maintenance: Designed for regular cleaning and tool replacement.

Safe and reliable: equipped with safety protection devices, such as emergency stop button, overload protection, etc.

| Model | 600 | 800 | 1000 | 1200 | 1400 | 1600 | 1800 |

| Motor(kw) | 11*2 | 18.5*2 | 35*2 | 45*2 | 55*2 | 75*2 | 110*2 |

Reducer | P6-P7 | P7-P8 | P8-P10 | P10-P12 | P11-P13 | P12-P16 | P14-P16 |

| Siemens or other motors, planetary reducers or other reducers can be customized according to customer requirements | |||||||

| Rotation Speed | 8-20rmp | 8-20rmp | 8-15rmp | 8-15rmp | 8-15rmp | 8-12rmp | 8-12rmp |

| Blades Diameter | 220-320 | 260-320 | 260-400 | 400-500 | 400-500 | 500 | 500 |

| Blades material | The material of the blades (55sicr, 5crsi, 9crsi, skd11, m6v, h13) can be customizedaccording to the customer's actual usage | ||||||

| Feeding Size | 1200*900mm | 1400*1000mm | 1600*1200mm | 1800*1300mm | 2000*1300mm | 2200*1700mm | 2400*2000mm |

| The size and appearance of the feeding hopper can be customized according to thecustomer's feeding situation | |||||||

| Weight(kg) | 1800 | 2500 | 3700 | 5500 | 7500 | 9500 | 13000 |

-

Twin-shaft shredders: ideal for efficient processing of waste and recycling materialsA double-shaft shredder is a mechanical device used to process waste and recycle materials. Its main feature is that it has two rotating shafts with serrated bl...Get Quote

Twin-shaft shredders: ideal for efficient processing of waste and recycling materialsA double-shaft shredder is a mechanical device used to process waste and recycle materials. Its main feature is that it has two rotating shafts with serrated bl...Get Quote -

Plastic double shaft shredderOperation:Feeding: The plastic material is fed into the shredder through the infeed system.Shredding: As the material enters the shredding chamber, the rotating...Get Quote

Plastic double shaft shredderOperation:Feeding: The plastic material is fed into the shredder through the infeed system.Shredding: As the material enters the shredding chamber, the rotating...Get Quote -

Hot-sell Coconut Shredderworking principleCoconut shell shredder usually uses the force generated by cone and spiral to evenly squeeze the coconut meat in the grinding chamber between t...Get Quote

Hot-sell Coconut Shredderworking principleCoconut shell shredder usually uses the force generated by cone and spiral to evenly squeeze the coconut meat in the grinding chamber between t...Get Quote -

Medical waste shredderWorking Principle:Feeding Mechanism: Medical waste is fed into the shredder through a hopper or chute. The feeding mechanism ensures that the waste is introduce...Get Quote

Medical waste shredderWorking Principle:Feeding Mechanism: Medical waste is fed into the shredder through a hopper or chute. The feeding mechanism ensures that the waste is introduce...Get Quote