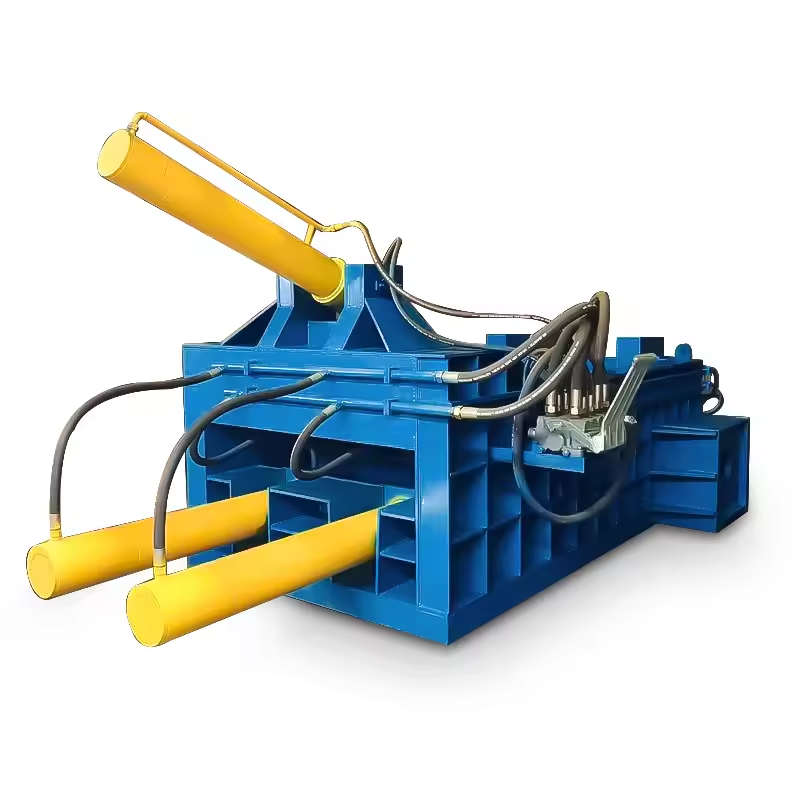

The Advantages of Horizontal Baling Technology

-

Production Capacity:

2000-3500kg/h

-

Applicable Industries:

Building Material Shops, Farms, Energy & Mining, Other, pressbaler, Waste recycling plant, metal baler

-

Power:

22

-

Core Components:

PLC

-

Place of Origin:

Henan, China

- Product Details

- Characteristics

- Working Principle and Application

- Parameters

Horizontal baling machines are used to compress materials such as waste paper, cardboard, plastic, textiles, and other recyclable materials. The compression process is typically done using hydraulic force, which allows the materials to be tightly packed into bales. These machines are essential in recycling facilities, manufacturing plants, and other industries where there is a need to efficiently manage and transport large volumes of waste materials.

-

01Robust Construction: Horizontal balers are built with sturdy materials to withstand the high pressures involved in the compression process.

-

02Versatility: These machines can handle a wide range of materials, making them suitable for various applications.

-

03Reduced Transportation Costs: By significantly reducing the volume of materials, they help lower shipping and storage costs.

-

04Efficient Design: They are designed to maximize efficiency, often featuring automated feeding and baling processes.

Working Principle:

The operation of a horizontal baler involves several key steps:

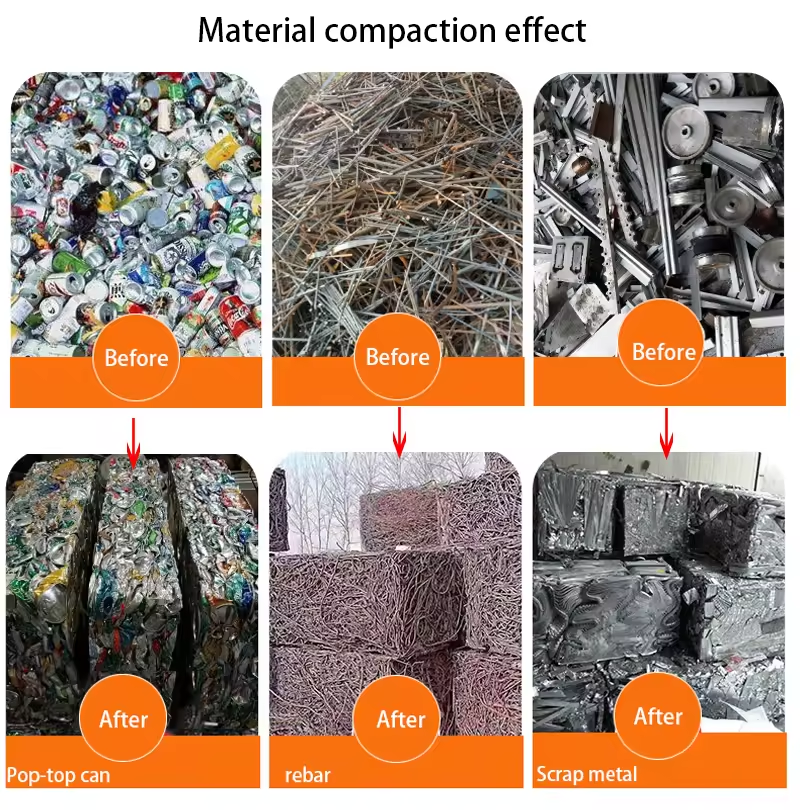

Loading: Materials to be compressed are fed into the machine through a horizontal chute or opening.

Compression: Inside the machine, a hydraulic ram or piston applies force to compress the materials into a compact form. The hydraulic system generates high pressure to achieve the required density.

Baling: Once the desired density is reached, the compressed materials are bound together using wire, straps, or other binding materials to maintain their shape.

Ejection: The finished bale is then ejected from the machine, ready for storage or transport.

Horizontal balers are widely used in various industries, including:

- Recycling Centers: Processing large volumes of recyclable materials such as paper, cardboard, plastics, textiles, and metals making machine.

- Manufacturing Facilities: Managing waste generated during production processes.

- Retail Stores and Supermarkets: Managing packaging waste.

- Agricultural Operations: Compressing agricultural byproducts such as straw, hay, and wool

| Type | Nominal push force(kn) | Dimension of compressed room(L*W*H)mm | Package block dimension(L*W)mm | Production efficiency(Kg/h) |

| Y81t-100A | 1000 | 1000*700*550 | 250*250 | 1200-1500 |

| Y81t-125A | 1250 | 1200*700*600 | 300*300 | 1200-1800 |

| Y81t-125Y | 1250 | 1200*700*600 | φ200 | 1200-1700 |

| Y81t-135 | 1350 | 1400*900*700 | 350*350 | 1800-2200 |

| Y81t-160 | 1600 | 1400*900*800 | 350*350 | 2000-3000 |

| Y81t-160A | 1600 | 1600*1000*800 | 400*400 | 2000-3500 |

| Y81t-160B | 1600 | 1600*1200*800 | 400*400 | 2000-4000 |

| Y81t-200A | 2000 | 1600*1200*800 | 450*450 | 2500-4500 |

| Y81t-200B | 2000 | 1800*1200*900 | 500*500 | 3000-5000 |

-

Recycling Balers-Safe,Easy-To-Use and affordableThe operating principle of a strapping machine primarily involves the following steps:1.Item Positioning:Firstly, the item to be strapped must be placed accurat...Get Quote

Recycling Balers-Safe,Easy-To-Use and affordableThe operating principle of a strapping machine primarily involves the following steps:1.Item Positioning:Firstly, the item to be strapped must be placed accurat...Get Quote -

The Advantages of Horizontal Baling TechnologyA horizontal baler, also known as a horizontal baling machine, is a piece of equipment used for compressing materials and wrapping them into bales. This process...Get Quote

The Advantages of Horizontal Baling TechnologyA horizontal baler, also known as a horizontal baling machine, is a piece of equipment used for compressing materials and wrapping them into bales. This process...Get Quote