Recycling Balers-Safe,Easy-To-Use and affordable

-

Production Capacity:

1.2-1.5t/h

-

Applicable Industries:

Manufacturing Plant, Retail, Construction works , Other

-

Power:

18.5kw

-

Core Components:

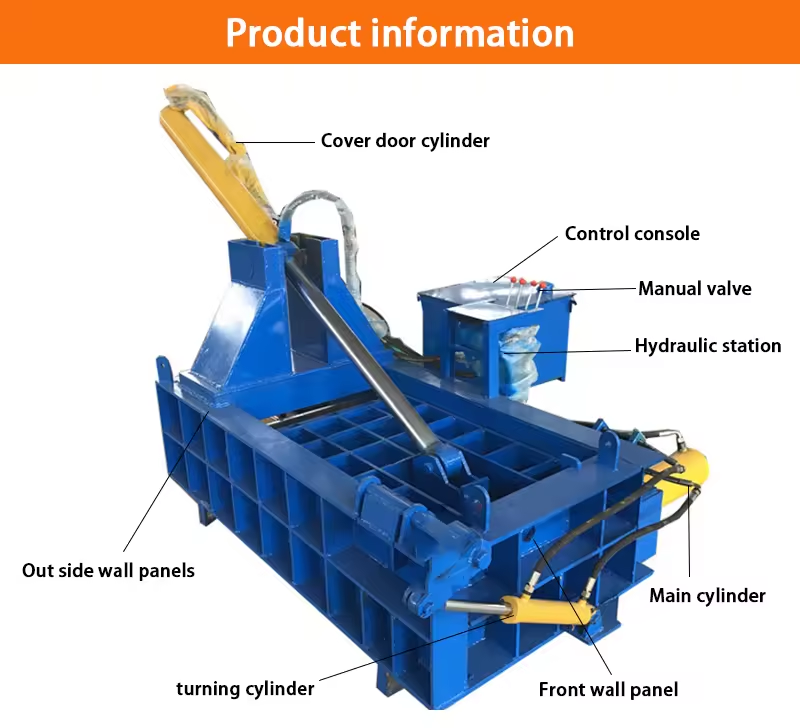

PLC, Gearbox, Motor, Pressure vessel, Pump

-

Place of Origin:

Henan, China

- Product Details

- Characteristics

- Working Principle and Application

- Parameters

Baler, also known as bundling machines, strapping applicators, or wrapping machines, are widely utilized mechanical devices in both industrial and commercial settings. Primarily, they are used to secure products or packaging units with strapping tape, ensuring stability and safety during handling, storage, and transportation. Strapping machines accomplish this by tightening the strapping tape and thermally welding its ends together using a heated sealing head, creating a secure bind that prevents items from scattering while maintaining a neat and presentable appearance.

-

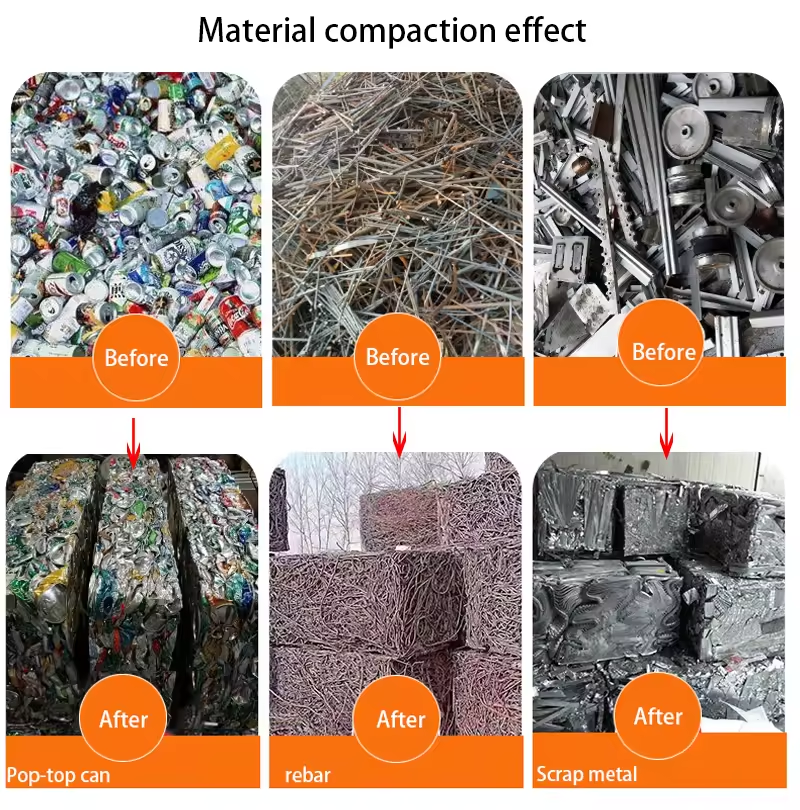

01Customized press box size and bale size.

-

02Designed with quick unit that can improve work efficiency substantially.

-

03Adaptability: Strapping machines are capable of handling items of various sizes and shapes, ranging from delicate small pieces to large heavy objects, with corresponding solutions available for each type.

-

04Ease of Operation: Many strapping machines feature user-friendly interfaces and automated control systems, which simplify operational procedures. Even untrained staff can quickly become proficient in their use.

The operating principle of a strapping machine primarily involves the following steps:

1.Item Positioning:Firstly, the item to be strapped must be placed accurately on the strapping machine's worktable.

2.Strapping Band Feeding:The strapping machine feeds out the strapping band (such as polypropylene or steel bands) from a reel, passing it around the item one or multiple times to create a loop structure.

3.Strapping Band Tensioning:The built-in tensioning mechanism of the strapping machine begins to operate, pulling the strapping band tight to ensure it closely conforms to the item, forming a stable wrap.

4.Strapping Band Sealing or Clamping:After the ends of the strapping band are pulled tight, the strapping machine seals the ends together using heat sealing or mechanically clamps them using metal buckles, creating a closed loop structure to complete the strapping process.

5.Excess Strapping Band Cutting:Upon completion of the strapping, the strapping machine automatically cuts off any excess strapping band, ensuring that the length of the band for each item is appropriate and does not interfere with subsequent operations.

Application Scenarios:

- Manufacturing Industry:

- Logistics and Warehousing:

- Retail Industry:

- E-commerce Industry

- Food Industry:

- Chemical Industry:

- Recycling Industry

| Model | Nominal thrust(kn) | Dimension of compress room (mm) | Baler dimension (mm) | Bale weight (kg) | Capacity(t/h) | Power(kw) |

| 63 | 630 | 1000*600*500 | 190*190 | 15-30 | 0.4-0.8 | 7.5 |

| 100 | 1000 | 1000*700*550 | 230*230 | 30-40 | 0.6-1.2 | 11 |

| 125 | 1250 | 1200*700*600 | 300*300 | 50-75 | 1.2-1.5 | 15 |

| 135 | 1350 | 1400*600*600 | 600*240 | 60-80 | 1.5-1.8 | 22 |

| 160 | 1600 | 1600*1000*800 | 400*400 | 110-150 | 2.2-3.0 | 22 |

| 200 | 2000 | 1800*1400*900 | 450*450 | 210-300 | 3.0-5.0 | 22 |

-

The Advantages of Horizontal Baling TechnologyA horizontal baler, also known as a horizontal baling machine, is a piece of equipment used for compressing materials and wrapping them into bales. This process...Get Quote

The Advantages of Horizontal Baling TechnologyA horizontal baler, also known as a horizontal baling machine, is a piece of equipment used for compressing materials and wrapping them into bales. This process...Get Quote -

Recycling Balers-Safe,Easy-To-Use and affordableThe operating principle of a strapping machine primarily involves the following steps:1.Item Positioning:Firstly, the item to be strapped must be placed accurat...Get Quote

Recycling Balers-Safe,Easy-To-Use and affordableThe operating principle of a strapping machine primarily involves the following steps:1.Item Positioning:Firstly, the item to be strapped must be placed accurat...Get Quote