Comprehensive Garbage Light Material Air Separator Equipment

1). Development Prospects:

With the acceleration of industrialization and the change of consumption patterns, the treatment of solid waste has become an increasingly severe challenge. Traditional garbage sorting and treatment methods are often unable to achieve high-energy, accurate sorting and recycling. However, the emergence of comprehensive garbage light material air separators provides an innovative solution to this problem.

2). Working Principle:

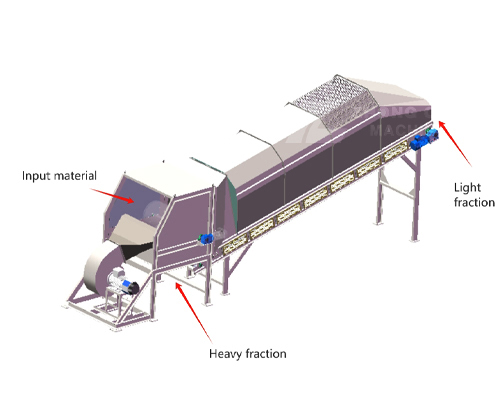

1. Comprehensive garbage light material air separator is a device that uses aerodynamic principles to effectively separate light materials such as plastic film, paper, etc. from heavy materials such as stone, metal, etc. through wind sorting.

2. The working principle of this equipment is based on the difference in the movement characteristics of different materials in the airflow. When the airflow passes through the material, the light material with low density, large surface area and large wind resistance will be blown up by the airflow and move in the direction of the airflow, while the heavier material will fall under the action of gravity due to the small wind force. In this way, the air separator can effectively separate light recyclables from other wastes, which facilitates subsequent recycling and treatment.

3). Advantages:

1. The advantages of the comprehensive garbage light material air separator are obvious. First, it has high sorting efficiency. In practical applications, the air separator can operate continuously, greatly increase the processing capacity, and meet the needs of large-scale garbage sorting. For example, in the treatment of decoration waste, the air separator can initially separate the light materials, and then further process them through other sorting equipment such as magnetic separators and screening machines, thereby significantly improving the quality of recycled aggregates and reducing subsequent processing costs.

2. Secondly, the air separator has good environmental performance. Because it does not use water or other chemical reagents, it avoids the risk of secondary pollution. At the same time, the optimized design of the air separation system reduces energy consumption and reduces resource waste and environmental pollution caused by misclassification. This is of great significance for promoting the development of green buildings and circular economy.

3. In addition, the structure of the comprehensive garbage light material air separator is simple, the maintenance cost is low, and it is suitable for long-term continuous work. This makes it widely used in the waste treatment industry. It is not only suitable for the treatment of urban solid waste, but also can be used in agriculture, forestry and other fields. For example, in the treatment of agricultural straw, the air separator can effectively separate the light straw from the heavy grains and improve the processing efficiency of crops.

4). However, it is worth noting that although the comprehensive garbage light material air separator has an outstanding sorting effect on light materials, its sorting effect may be affected for materials with similar density or irregular shape. Therefore, in practical applications, it is often necessary to combine it with other sorting technologies such as magnetic separation and screening to achieve a good sorting effect.

5). Specification:

| Air Separator 800 | Air Separator 1200 | Air Separator 1600 | |

| Feeding Belt Width | 800mm | 1200mm | 1600mm |

| Air volume | 8000-19000 m³/h | 12000-29000 m³/h | 15000-35000 m³/h |

| Full pressure | 2500Pa | 2500Pa | 2500Pa |

| Power | 38kw | 42kw | 55kw |

| Throughput | 20-30 m³/h | 30-50 m³/h | 50-70 m³/h |

-

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote -

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote -

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

-

2023-01-18RDF Making MachineRDF (Refuse Derived Fuel) making machine is a specialized equipment used in waste management and energy recovery processes. Its primary function is to convert v...

-

2025-04-21Compact Copper Cable Granulator MachineThe compact copper cable granulator machine is a device used to recycle waste wires and cables. It separates the copper wire from the plastic sheath by crushing...

-

2024-08-22Medical waste shredderWorking Principle:Feeding Mechanism: Medical waste is fed into the shredder through a hopper or chute. The feeding mechanism ensures that the waste is introduce...

-

2023-01-11Ballistic SeparatorBallistic separators are a crucial component in modern recycling and waste management systems, contributing to more efficient resource recovery and environmenta...

-

2024-08-05Hot-sell Coconut Shredderworking principleCoconut shell shredder usually uses the force generated by cone and spiral to evenly squeeze the coconut meat in the grinding chamber between t...