Advancements in Baling Press Technology Drive Efficiency and Sustainability in Waste Management and Recycling

Introduction to Baling Presses

A baling press, also known as a baler or compactor, is a machine designed to compress various materials into compact bundles or bales. These machines are widely used in industries such as waste management, recycling, agriculture, and manufacturing to reduce the volume of materials, making them easier to handle, store, and transport. Common materials processed by baling presses include paper, cardboard, plastics, metals, textiles, and agricultural residues like straw and hay.

Market Development and Prospects

Global Market Trends: According to a 2023 report on the global waste compactor market development prospects, it is expected that the global waste compactor market will continue to grow rapidly over the next few years. This growth is primarily driven by the acceleration of urbanization, increased public awareness of environmental protection, and government support for waste management policies.

Technological Innovation: Howei Environmental Technology Co., Ltd., one of China's early suppliers of small solid waste recycling machinery, has improved the technical level and product quality of domestic baling presses by introducing and absorbing advanced European hydraulic baling press production technology. These technological advancements not only enhance the efficiency of the equipment but also strengthen its competitiveness in the international market.

Environmental Contribution: Orkel's high-density baling technology has played a significant role in the resource utilization of waste, contributing to the construction of "waste-free cities." By efficiently compressing and baling waste, it reduces pressure on landfills and promotes the development of a circular economy.

Working Principle

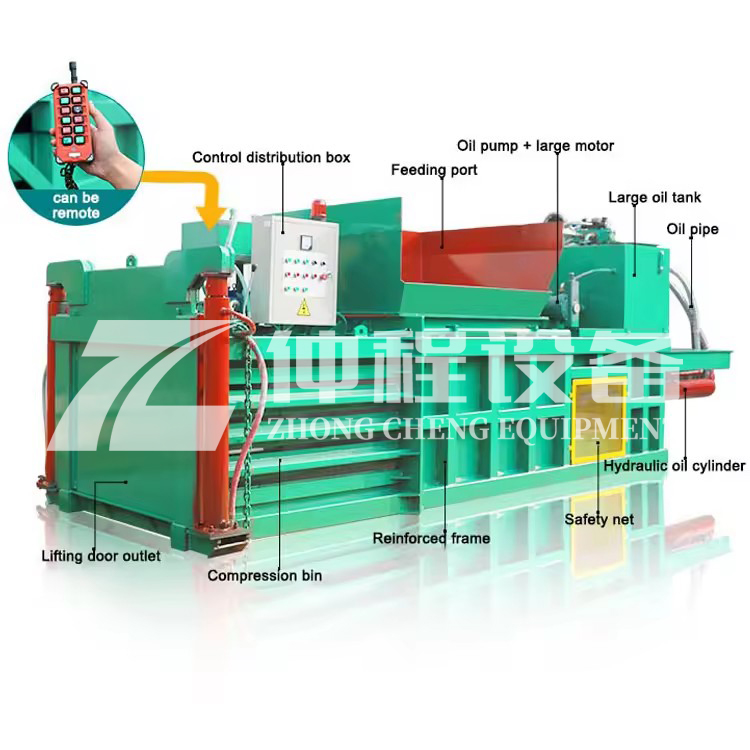

Baling presses operate based on physical compression, using high pressure generated by hydraulic or pneumatic systems to reduce the volume of materials. Common types of baling presses include hydraulic-driven and pneumatic-driven models, with hydraulic-driven ones being more prevalent due to their ability to provide greater compressive force, making them suitable for handling larger or harder materials.

Application Cases

- Marine Applications: Shipboard baling presses are widely used on ships, cruise liners, and other offshore platforms, effectively addressing waste disposal issues and reducing environmental impact.

Agricultural Applications: High-density straw silage baling presses have demonstrated their value in agricultural waste management by compressing corn stalks and other agricultural by-products into blocks. This makes storage and transportation more convenient and provides new value-added opportunities for agricultural production.

Key Features and Benefits

Volume Reduction: Baling presses significantly reduce the volume of materials, making them easier to handle, store, and transport. This can lead to cost savings in transportation and storage.

Efficiency: Modern baling presses are designed to be highly efficient, with automated processes that minimize labor requirements and maximize throughput.

Safety: Many baling presses come with safety features such as interlocks, emergency stop buttons, and protective guards to ensure safe operation.

Environmental Impact: By reducing the volume of waste, baling presses help minimize the environmental impact of waste disposal. They promote recycling and the efficient use of resources, contributing to sustainable practices.

Applications

Waste Management: Baling presses are essential in waste management facilities for compressing and baling various types of waste, reducing the amount of space required for storage and transportation.

Recycling: In recycling centers, baling presses help prepare materials for further processing by compressing them into manageable bales.

Agriculture: High-density baling presses are used in agriculture to compress straw, hay, and other crop residues into bales, facilitating storage and transportation.

Manufacturing: In manufacturing plants, baling presses are used to compress scrap materials, such as metal shavings and plastic waste, for recycling or disposal.

-

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote -

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote -

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

-

2024-06-08Solutions for Jaw Crusher ProblemsJaw crusher is widely used in mining, smelting, building materials, highways, railways, water conservancy and chemical industries. The maximum compressive stren...

-

2023-01-18Metal BalerMetal baler, specifically a hydraulic metal baler, is a machine designed to compress scrap metal into dense, manageable bales. This equipment is widely used in ...

-

2024-06-20Wind Separator Technology for Lightweight Materials in Urban Solid Wastewind separator, also known as air separation, is a sophisticated and efficient method of sorting that utilizes air as the separating medium.

-

2025-04-21Compact Copper Cable Granulator MachineThe compact copper cable granulator machine is a device used to recycle waste wires and cables. It separates the copper wire from the plastic sheath by crushing...

-

2023-01-12Conveyor BeltGarbage conveyor/Trash conveyor belt system is a processing line to classify paper, plastic, metal, glass, and organic matter and realize the recycling of rubb...