Windsifter has high efficiency and reliability in material separation

Windsifters are at the forefront of material separation technology, renowned for their exceptional efficiency and reliability in handling

various types of materials. This article exploresthe capabilities of windsifters, their operational advantages, and their significance in

modern industrial processes.

Understanding Windsifters: Efficiency and Reliability in Material Separation

Introduction to Windsifters

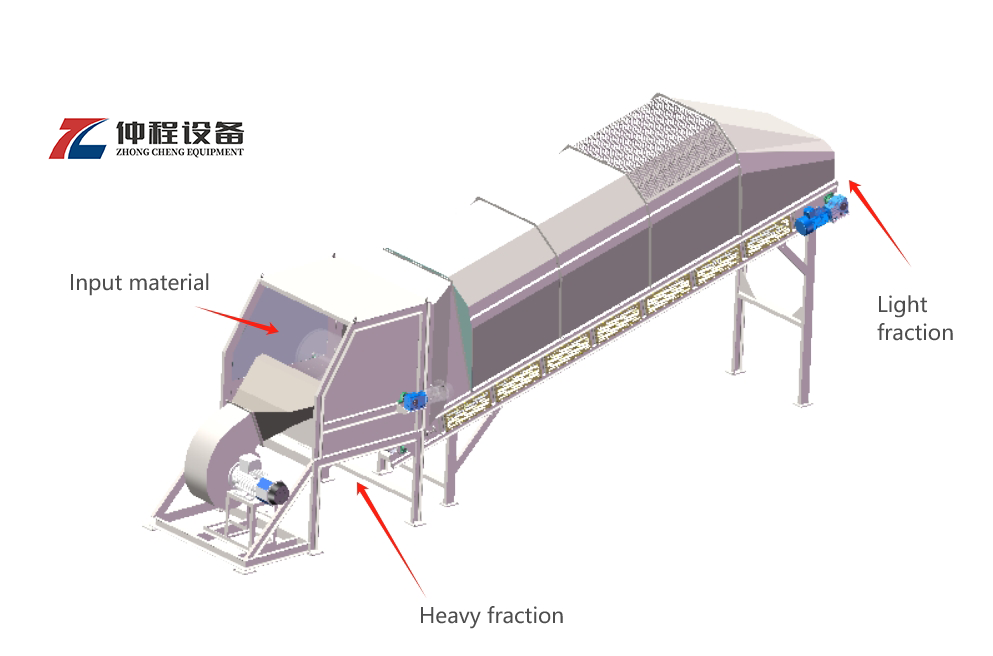

Windsifters are advanced equipment used primarily for the separation of light materials such as film, fiber, and grit from material

streams. They are designed to achieve high levels of efficiency while maintaining reliability, making them indispensable in

industries where precise material sorting is crucial.

Efficiency in Material Separation

One of the primary strengths of windsifters lies in their efficiency. They are capable of effectively separating different types of

materials based on size, density, and composition.

This capability is particularly valuable in recycling processes, where the separation of materials like plastics and fibers from mixed

waste streams is essential.

Reliability and Durability

In addition to efficiency, windsifters are highly reliable and durable. They are built to withstand continuous operation under varying

conditions without compromising performance. This reliability ensures consistent output and minimal downtime, which is critical for

maximizing productivity in industrial settings.

Operational Advantages

Low Maintenance Requirements

Windsifters are designed with simplicity in mind, requiring minimal maintenance. Unlike other sorting technologies that may involve

frequent adjustments or part replacements, windsifters operate smoothly with little intervention, reducing operational costs and

downtime.

Jam-Free Operation

Another significant advantage of windsifters is their ability to operate without jamming. This is achieved through innovative design

features and technologies that prevent material blockages, ensuring uninterrupted processing and maintaining high throughput.

Features of Windsifters

Versatility in Material Handling

Windsifters offer versatility in handling a wide range of waste streams and materials. They can effectively process materials such

as glass, paper, plastics, and organic matter, adapting to the specific needs of different industries and applications.

Adjustable Settings for Enhanced Efficiency

To optimize separation efficiency, windsifters are equipped with adjustable settings. Operators can customize parameters such as

airflow, conveyor speed, and separation thresholds to achieve the desired level of material purity and throughput.

Energy Efficiency

Despite their high performance, windsifters are designed to be energy-efficient. They incorporate features like recirculation fans

and optimized airflow systems to minimize energy consumption, aligning with sustainability goals and reducing operational costs.

Applications and Industries

Windsifters find application across various industries including recycling facilities, waste management centers, and manufacturing

plants. Their ability to improve material purity and facilitate recycling processes contributes significantly to environmental

sustainability efforts.

Conclusion

In conclusion, windsifters represent a cornerstone in modern material sorting technology. With their high efficiency, reliability, and

minimal maintenance requirements, they play vital role in enhancing operational efficiency and reducing environmental impact. As

industries continue to prioritize sustainability and resource efficiency, windsifters are expected to remain integral to the future of

material processing.

FAQs About Windsifters

What types of materials can windsifters effectively separate?

Windsifters are effective in separating light materials such as film, fiber, and grit, as well as heavier materials like glass and plastics.

How do windsifters contribute to reducing operational costs?

Windsifters reduce operational costs by minimizing downtime through their low maintenance requirements and jam-free operation.

Are windsifters suitable for large-scale industrial applications?

Yes, windsifters are designed for high-volume processing and are suitable for use in various industrial settings.

What are the environmental benefits of using windsifters?

By enhancing recycling capabilities and reducing landfill waste, windsifters contribute to environmental sustainability by conserving

resources and reducing pollution.

Can windsifters be integrated into existing processing lines easily?

Yes, windsifters are typically designed for easy integration into existing processing lines, offering flexibility and operational convenience.

This article has provided insights into the efficiency and reliability of windsifters in material separation, highlighting their role in

advancing industrial processes and sustainable practices.

-

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote -

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote -

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

-

2024-08-20A rubber double shaft shredderExamples of Specific Models:GDB Series Biomass Shredder: Although primarily designed for biomass materials, this model can also be configured to handle various ...

-

2023-01-12Impact CrusherImpact crusher is a type of machine designed to reduce large rocks, ores, and other hard materials into smaller, more manageable pieces. This equipment is widel...

-

2023-01-11Ballistic SeparatorBallistic separators are a crucial component in modern recycling and waste management systems, contributing to more efficient resource recovery and environmenta...

-

2024-06-07Zhongcheng Air Drum Separator in MSWAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...

-

2023-01-12Double-Shaft ShredderThe Double-shaft shredder is a widely used industrial shredder that efficiently processes various mixed waste materials, such as construction waste, industrial ...