Mastering the Mechanics: How Horizontal Balers Compress and Bind Materials Effortlessly

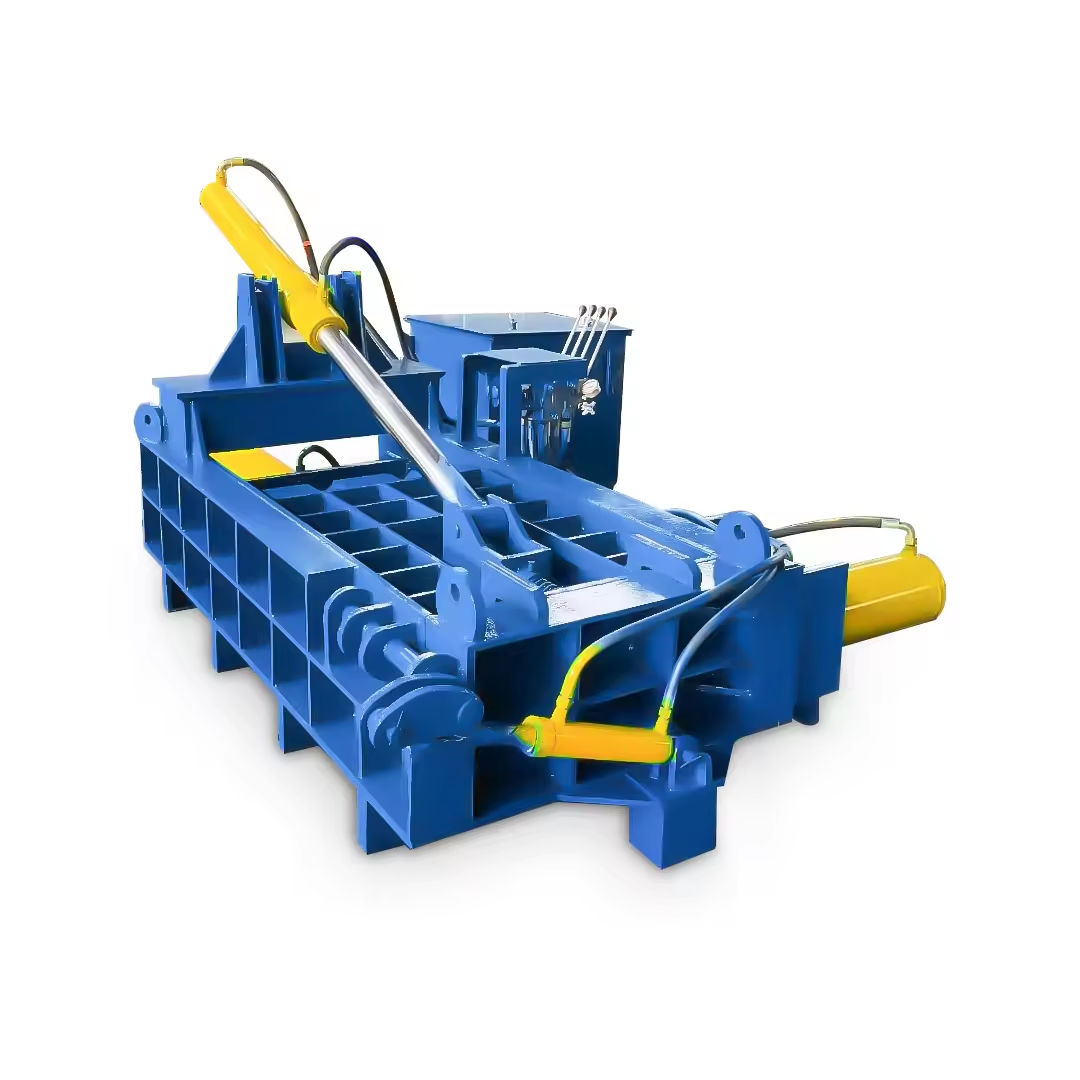

The hydraulic packaging machine is composed of mechatronics integration, and the entire packaging process consists of auxiliary time such as pressing, returning, lifting, rotating, upward and downward packaging, and receiving. Can be used for compressing and packaging soft materials such as straw, grass, waste paper, cotton, clothing, plastic, wool, recycled waste cardboard boxes, waste cardboard, etc., greatly reducing volume, increasing density, and facilitating transportation and storage.

After compressing, the metal bale is easy to transport and store, so it can save transporation cost, reduce storage area and reduce the loss when smelting. Easy operation, durable and long service life, high efficiency, etc.

Features :

1.All machines are hydraulic-driven with alternatives of manual or automatic control .

2.Bale-discharging alternative : turn-out , push-out , forward or manual discharging .

3.No fang bolts needed for installation ; diesel engine can be used as power when electric power is unavailable .

4.There are ten grades of baling force from 63 to 400 tons .

The size of baler can be custom made as per customers .

Applications:

Waste Paper Recycling Industry:

- Used to compress waste paper, newspapers, magazines, and other paper products before recycling.

Plastic Recycling Industry:

- Used for compacting PET bottles, plastic films, plastic containers, and other plastic waste.

Textile Industry:

- Used for baling fabrics, cotton, clothing, and other textile products for easier transport.

Metal Processing Industry:

- Used to compact thin metal sheets, aluminum cans, and other scrap metals.

Agricultural Sector:

- Used for baling straw, hay, and other agricultural by-products.

Food Processing Industry:

- In some cases, used for packaging dry fruits, tea leaves, and similar food products.

Logistics and Warehousing:

Used in logistics centers to compact goods and save space.

Working Principle of Horizontal Baler

Feeding of Materials:

- The materials to be baled are fed into the machine through a feeding chute or conveyor.

- In automatic systems, this process is typically automated, while in semi-automatic systems, it may require manual assistance.

Compaction:

- Once inside the baler, the materials are compacted by a hydraulic ram that applies pressure.

- The hydraulic ram moves back and forth, pushing the material into a smaller volume, increasing its density.

Baling:

- After the material is sufficiently compacted, a wire or strapping mechanism is activated.

- A wire or strap is fed around the compressed material, securing it in place.

- The wire or strap is then tightened and sealed using heat or mechanical means, creating a stable bale.

Ejection:

- Once the bale is secured, the hydraulic ram retracts, and the bale is ejected from the machine.

- In some models, the bale is automatically pushed out onto a conveyor belt or pallet.

Resetting:

- After ejection, the machine resets itself to prepare for the next cycle.

- This includes resetting the hydraulic ram and any other components involved in the baling process.

Continuous Cycle:

- The process repeats continuously until all the material has been processed or the operator stops the machine.

This method ensures that the materials are tightly packed and securely bound, making them easier to handle and transport. The compacted bales also take up less storage space and are more efficient for recycling or disposal processes.

-

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote -

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote -

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

-

2023-01-18RDF Making MachineRDF (Refuse Derived Fuel) making machine is a specialized equipment used in waste management and energy recovery processes. Its primary function is to convert v...

-

2024-04-13Wobbler FeederWobbler feeder is a type of feeding equipment that uses rotating elliptical bars, known as wobblers, to separate materials based on size and type before they re...

-

2024-05-20Mobile Impact Crusher PlantThe mobile impact crusher plant is a kind of crushing equipment based on a mobile platform. It uses an impact crusher as the host machine and is usually equippe...

-

2023-01-12Impact CrusherImpact crusher is a type of machine designed to reduce large rocks, ores, and other hard materials into smaller, more manageable pieces. This equipment is widel...

-

2024-06-08Five factors influencing the output of a drum screen.The input efficiency and separation efficiency of the drum screen are controlled by the screen hole size, drum screen diameter, rotation speed, baffle type and ...