Efficient compression, easy packaging - boost your business efficiency

The production of metal balers is suitable for steel mills, recycling and processing industries and non-ferrous and ferrous metal smelting industries. Various metal scraps, steel shavings, scrap steel, scrap aluminum, scrap copper, etc. can be extruded into rectangular, cylindrical, octagonal and other shapes of qualified charge to reduce transportation and torch costs.

After compressing, the metal bale is easy to transport and store, so it can save transporation cost, reduce storage area and reduce the loss when smelting. Easy operation, durable and long service life, high efficiency, etc.

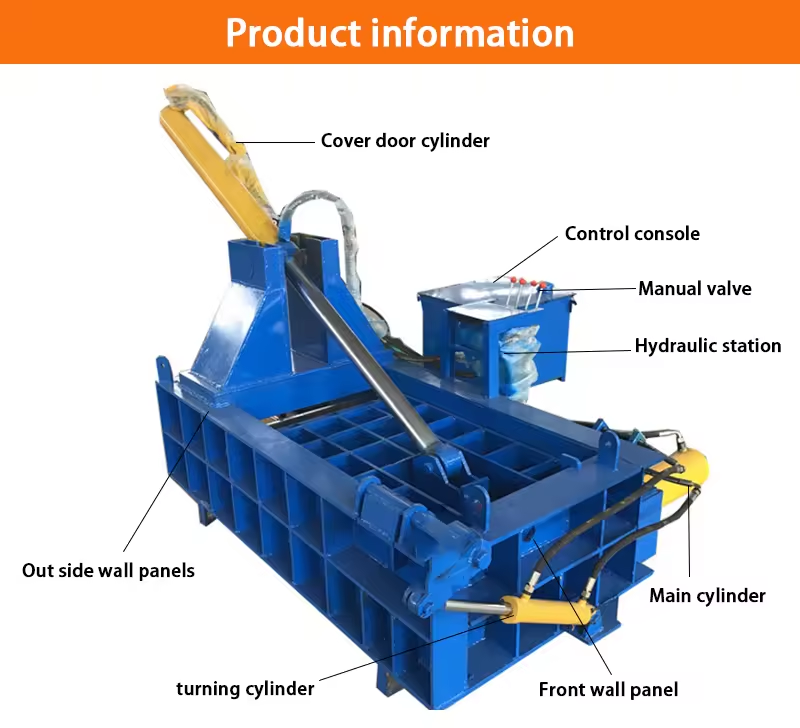

Main Features of scrap metal compactor baler

1.The discharging types fall into turning over, push out ,forward out and manual lifting.

2.It is unnecessary to fix foot screw and a diesel engine can be used in case of power supply unavailability.

3. Smooth operation; computer control, high degree of automation, low failure rate, easy maintenance and so on.

4.The extrusion force ranges from 63t to 400t ,totaling 10 grades for customers' selection ,and productivity being from 3.2t/shift to 64t/shift .

Application:

Waste Management and Recycling Industries - These sectors utilize baling presses to compact materials like paper, cardboard, plastic, and textiles, making them easier to store and transport.

Agricultural Sector - In agriculture, baling presses are used for compressing hay, straw, and other agricultural byproducts into manageable bales.

Manufacturing Industries - Various manufacturing industries use baling presses to manage waste materials generated during production processes, such as scrap fabric or plastic offcuts.

Textile Industry - Textile manufacturers often use these machines to compact textile waste, which can then be recycled or disposed of more efficiently.

Plastic Processing Industry - Companies that deal with plastics use baling presses to compact plastic waste, including bottles, films, and containers, before recycling.

Paper and Pulp Industry - Baling presses help in compacting paper and cardboard waste, aiding in the recycling process.

Household and Commercial Waste Collection Services - These services may use baling presses to compact general waste, reducing volume and improving logistics.

The working principle of a baling press (also known as a baler or a baling machine) can be explained as follows:

A baling press is a machine designed to compress loose material into compact bundles or bales, typically using a hydraulic system. The process usually involves the following steps:

Material Intake: Loose material, such as paper, cardboard, plastic, textiles, or agricultural products like hay, is fed into the machine.

Compression: A compression chamber or platen within the machine applies force to the material, using hydraulic cylinders to create pressure and compact the material into a dense form.

Bale Formation: Once the material is sufficiently compressed, it is held in place while a tying mechanism wraps wire, string, or plastic straps around the bale to hold it together.

Ejection: The finished bale is then ejected from the machine, and the process repeats with new material being introduced into the compression chamber.

Here's a concise explanation of the working principle in English:

The baling press works by using hydraulic power to compress loose materials into compact bales. The material is fed into a compression chamber, where hydraulic cylinders apply significant force to reduce its volume. Once the material is sufficiently compressed, a tying mechanism secures the bale with wire, string, or plastic straps. The bale is then ejected from the machine, and the process repeats with new material.

This process makes it easier to handle, transport, and store the compressed materials, and it is particularly useful in waste management, recycling, and agricultural industries.

-

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote -

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote -

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

-

2023-01-12WindshifterWindshifter (Air Drum Separator ) is the ideal solution for separating all kind of waste types into two fractions, heavy and light. The robust construction and ...

-

2024-06-05Waste Trommel And Copmost TrommelHowever, it's important to choose the right type of drum screen based on your specific needs. Today, Kevin from Zhongcheng Company will explain the differences...

-

2024-08-16Crop straw double shaft shredderApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...

-

2024-06-06Drum Screen For Composting PlantDrum screen, also known as a rotary drum screen or trommel screen, is an essential piece of equipment used in composting plants for the separation of compost ma...

-

2023-01-12Impact CrusherImpact crusher is a type of machine designed to reduce large rocks, ores, and other hard materials into smaller, more manageable pieces. This equipment is widel...