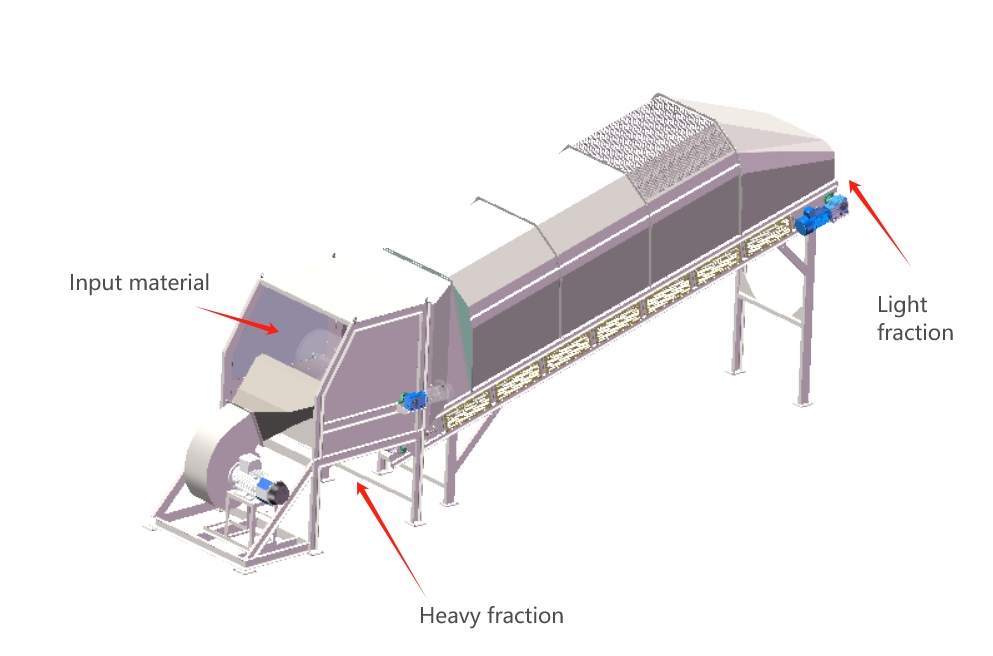

Windsifter for garbage sorting equipment

1. )What is a windsifter?

A windsifter is a device that screens materials through airflow. Its main principle is to use the power of high-speed airflow to separate the light and heavy particles in the material, so as to achieve the purpose of screening and classification of the material. Windsifter are widely used in food, chemical, metallurgical, building materials and other industries, with the characteristics of high degree of automation, simple operation and high screening accuracy.

2. )Working principle of Windsifter

1. Airflow generation: Air is introduced into the wind separator through the air inlet, and high-speed airflow is generated after compression and decompression.

2. Material separation: Under the action of high-speed airflow, the screened materials produce different forces due to their different weights and densities, thereby achieving material separation. Heavier particles will fall due to inertia, and light particles will be sucked up by the airflow and separated by different discharge methods.

3. Discharge and discharge: The discharge port can be adjusted accordingly according to different outputs and material characteristics to achieve material separation. Discharge methods include cyclone separation, vibration separation, centrifugal separation, etc.

3. )Application scenarios of windsifter

1. Food processing: windsifter can be used for the selection and screening of foods such as starch, dried nuts, and biscuits.

2. Chemical industry: windsifter can be used for the separation and screening of granular materials such as alumina, titanium dioxide, and powder coatings.

3. Metallurgical industry: windsifter can be used for the classification and screening of manganese ore, chromium ore, bauxite, and other metallurgical materials in the steel industry.

4. Construction industry: windsifter can be used for the selection and screening of building materials such as quartz sand, limestone, and cement.

In short, as a device for separating particles, windsifter have a wide range of applications. The models and operating procedures of windsifter in different industries will also be slightly different. When using an windsifter, it is necessary to adjust and operate it according to the specific situation to achieve the best separation effect.

-

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote -

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote -

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

-

2023-01-12Apron FeedersApron Feeder is a conveyor manufactured from steel plates driven by steel chains wearing on steel surfaces. They are a robust design manufactured for durability...

-

2024-06-08Five factors influencing the output of a drum screen.The input efficiency and separation efficiency of the drum screen are controlled by the screen hole size, drum screen diameter, rotation speed, baffle type and ...

-

2024-06-11Optimize Your Waste Management Today with Our Advanced Drum ScreensUnderstanding the Mechanism and Optimization of Drum Screens for Waste Management

-

2024-06-09Advantages of Using Drum Screening Machines in Waste ManagementUnderstanding the working principle of drum screening machines is essential to appreciate their efficiency and effectiveness in waste management. Operation and ...

-

2024-08-05Hot-sell Coconut Shredderworking principleCoconut shell shredder usually uses the force generated by cone and spiral to evenly squeeze the coconut meat in the grinding chamber between t...