Trommel Screens in German Bottle Recycling Machines

Germany is globally recognized as a leader in recycling, boasting one of the highest recycling rates in the world. Central to this success are advanced recycling technologies that ensure the efficient and effective processing of waste materials, particularly bottles. Among these technologies, the trommel screen stands out as a crucial component in bottle recycling machines. This article explores the role of trommel screens in German bottle recycling machines, detailing how they contribute to the overall recycling process and the benefits they offer in promoting sustainable practices.

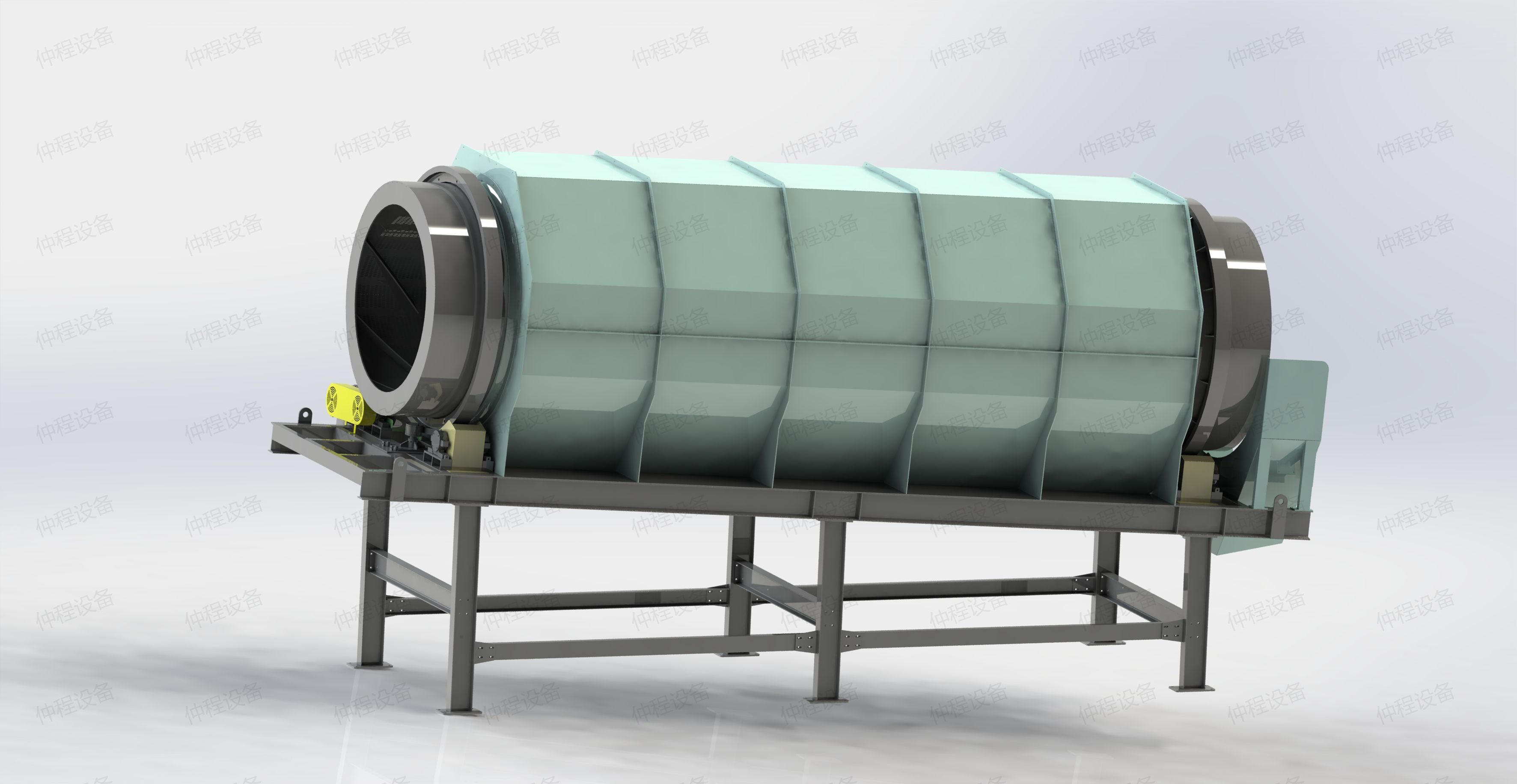

Introduction to Trommel Screens

A trommel screen, also known as a rotary screen, is a mechanical screening machine used to separate materials based on size. It consists of a rotating cylindrical drum with perforated sides. As the drum rotates, materials are fed into it and passed through the perforations. The smaller particles fall through the holes and are collected, while larger materials continue to travel through the drum until they are discharged.

Trommel screens are highly versatile and are used in various industries, including waste management, mining, and agriculture. In the context of recycling, trommel screens are particularly valuable for their ability to sort different types of waste efficiently, making them an integral part of bottle recycling machines in Germany.

How Trommel Screens Work in Bottle Recycling

In the bottle recycling process, the first step is to collect and sort the bottles. German recycling systems typically handle a mix of materials, including plastic, glass, and aluminum bottles. To effectively sort these materials, recycling facilities rely on a combination of mechanical and automated sorting technologies, with trommel screens playing a vital role in the initial sorting phase.

When bottles enter the recycling facility, they are first fed into a trommel screen. The rotating drum of the trommel screen allows the bottles to be separated based on their size. Smaller particles, such as caps, labels, and broken glass, pass through the perforations in the drum, while larger items, like intact bottles, continue to move through the screen. This initial separation is crucial for ensuring that the subsequent stages of the recycling process can operate smoothly.

Integration with Other Sorting Technologies

While trommel screens are effective for size-based sorting, they are often used in conjunction with other sorting technologies to achieve a more comprehensive separation of materials. In German bottle recycling machines, trommel screens are typically followed by other advanced sorting systems, such as:

Optical Sorters: These machines use sensors to identify materials based on their optical properties, such as color and transparency. After the initial size-based separation by the trommel screen, optical sorters can further categorize the bottles into different types, such as clear PET, colored PET, and glass.

Eddy Current Separators: These are used to separate non-ferrous metals like aluminum from the waste stream. Once the bottles have been sorted by size and material type, eddy current separators can remove any aluminum cans or other metallic materials that may still be present.

Ballistic Separators: These machines separate materials based on their density and shape. After passing through the trommel screen, the remaining materials can be further sorted by ballistic separators, which effectively distinguish between flat items (like labels and paper) and 3D objects (like bottles).

By integrating trommel screens with these additional sorting technologies, German recycling facilities can achieve a high level of precision in the separation process, ensuring that each material type is correctly identified and processed for recycling.

Advantages of Using Trommel Screens in Bottle Recycling

The use of trommel screens in bottle recycling offers several significant advantages:

Efficiency: Trommel screens can handle large volumes of materials at a time, making them ideal for high-capacity recycling facilities. Their ability to perform continuous sorting helps to streamline the recycling process, reducing bottlenecks and improving overall efficiency.

Versatility: Trommel screens can be adjusted to accommodate different sizes of materials, allowing for flexibility in processing various types of bottles. This versatility makes them suitable for a wide range of recycling applications.

Durability: Built to withstand harsh conditions, trommel screens are durable and require minimal maintenance. Their robust design ensures that they can operate effectively over long periods, even when processing abrasive or challenging materials like glass.

Cost-effectiveness: By providing an efficient means of initial sorting, trommel screens help to reduce the need for manual labor and other more expensive sorting technologies. This cost-effectiveness is particularly beneficial for recycling facilities looking to optimize their operations.

The Future of Trommel Screens in Recycling

As the global emphasis on sustainability continues to grow, the demand for efficient recycling technologies is expected to increase. Trommel screens, with their proven track record in bottle recycling, are likely to remain a key component in recycling systems worldwide. In Germany, where recycling is a well-established practice, ongoing innovations in trommel screen design and integration with other technologies will further enhance their effectiveness, contributing to even higher recycling rates and more sustainable waste management practices.

Conclusion

Trommel screens play an essential role in the German bottle recycling process, providing an efficient and reliable method for the initial sorting of materials. By separating bottles based on size, trommel screens help to prepare materials for further processing, ensuring that each type of bottle is correctly sorted and recycled. When combined with other advanced sorting technologies, trommel screens contribute to the high level of precision and efficiency that characterizes German recycling systems. As the world continues to focus on sustainability, the role of trommel screens in recycling is poised to become even more critical, supporting the global effort to reduce waste and promote environmental stewardship.

-

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote -

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote -

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

-

2024-08-12Wood Pallet ShredderConsiderations When Choosing a Wood Pallet Shredder:Material Type: Different wood types may require specific configurations or materials of construction.Output ...

-

2024-05-18Spring Cone CrusherSpring cone crushers are generally used in the medium and fine crushing links of mine crushing, and are mainly used in the secondary crushing and tertiary crush...

-

2023-01-12Waste FeederWaste feeder was specially designed to optimize municipal solid waste sorting systems. The Drum Feeder ensures that your sorting system, baler or shredder has a...

-

2024-06-09Advantages of Using Drum Screening Machines in Waste ManagementUnderstanding the working principle of drum screening machines is essential to appreciate their efficiency and effectiveness in waste management. Operation and ...

-

2024-06-05Can the Angle of the Ballistic Separator Be Adjusted?Ballistic separator is a type of mechanical sorting device used primarily in the recycling industry to separate materials based on their physical properties. It...