Trommel Screens machine in Material Separation

Trommel screens are highly versatile and efficient machines widely used for the separation of materials based on size, shape, and density. Originally developed for use in the mining industry, these machines have since become essential in a wide range of industries, from municipal solid waste (MSW) processing to construction and demolition waste, as well as in the recycling of plastics, glass, metals, and compost. The primary goal of trommel screens is to segregate materials in a way that enhances processing efficiency, reduces contamination, and promotes environmental sustainability.

Working Principle of Trommel Screens

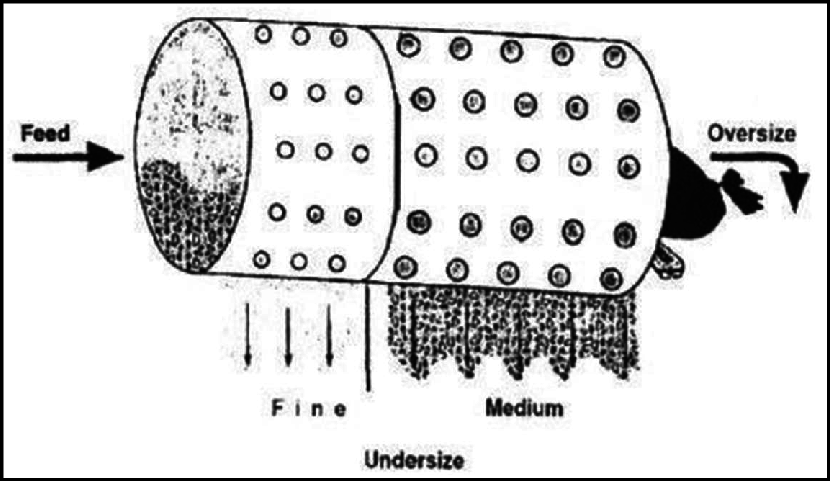

Trommel screens consist of a large rotating drum or cylindrical screen that has perforations or mesh openings of varying sizes. As material is fed into the rotating drum, smaller particles pass through the perforations while larger particles remain inside the drum and exit from the end. This process effectively separates the material based on size, shape, and density. The angle and rotation speed of the drum, as well as the size of the perforations, can be adjusted depending on the material being processed and the desired output.

Separation of Materials by Size, Shape, and Density

Trommel screens are primarily used to separate materials based on size. This is achieved by designing the drum with progressively smaller perforations. For example, in the case of municipal solid waste (MSW), larger items such as cans, bottles, and cardboard will be retained in the drum while smaller particles like sand, dirt, and broken glass will fall through the perforations. This size-based separation helps downstream processes, such as sorting or recycling, by removing large items and contaminants early in the process.

In addition to size, trommel screens are also effective in sorting materials based on shape and density. This is particularly important in industries that deal with a variety of mixed materials, such as construction waste or composting. Heavy, dense materials like stones and metals are separated from lighter items like plastics, foam, and organic matter, which tend to move differently through the rotating drum. The machine’s ability to differentiate materials based on density contributes to a cleaner and more uniform final product.

Applications of Trommel Screens

- Municipal Solid Waste (MSW) Processing

One of the most important uses of trommel screens is in the processing of municipal solid waste (MSW). This waste, composed of household garbage, yard trimmings, and small amounts of commercial waste, often contains a mixture of organic and inorganic materials of varying sizes. Trommel screens help by separating the waste into more manageable components. For instance, organic waste like food scraps and garden waste can be isolated for composting or further processing, while plastics, metals, and glass can be directed to appropriate recycling streams. This early stage sorting is crucial in minimizing landfill use and maximizing the amount of material that can be recycled or repurposed.

- Recycling and Resource Recovery

Trommel screens are a key component in modern recycling plants. These machines allow facilities to efficiently separate various recyclables, such as metals, plastics, and paper, by size and density. In particular, they are useful for the separation of shredded or crushed materials, helping to produce cleaner, higher-quality recyclables. For instance, when processing construction and demolition debris, trommel screens can easily remove small contaminants like soil and dust, while larger items like wood, concrete, and metal are directed to separate recycling streams. This ensures that materials are adequately separated and ready for reprocessing.

- Composting and Organic Waste Management

In the composting industry, trommel screens are used to separate compostable organic material from non-compostable contaminants. For example, composting facilities often receive yard waste mixed with plastics, stones, and other non-organic materials. A trommel screen can efficiently remove these contaminants, leaving behind a cleaner organic product that can decompose into nutrient-rich compost. Furthermore, trommel screens are often employed to screen finished compost to ensure uniform particle size, which improves the quality of the compost for agricultural or horticultural use.

- Mining and Aggregate Industries

Although the use of trommel screens has expanded to many industries, their origins lie in the mining sector. Trommel screens are still widely used in mining operations to separate valuable minerals from waste rock. The screen can be designed to separate materials based on both size and density, which is particularly useful when processing ores containing gold, copper, or other heavy minerals. In the aggregate industry, trommel screens are employed to separate materials such as gravel, sand, and crushed stone, which are essential for construction and infrastructure projects.

![P6E9]BBBM%]D]]1Z)3%42TQ.png](/uploads/allimg/20240913/1-240913095425634.png)

Advantages of Using Trommel Screens

One of the main advantages of trommel screens is their versatility. They can be configured to handle a wide variety of materials, making them ideal for industries that deal with mixed or contaminated waste. Furthermore, they are relatively simple to operate and maintain, with fewer moving parts compared to other types of sorting equipment. This results in lower operational costs and less downtime due to mechanical failures.

Another benefit of trommel screens is their efficiency. By accurately separating materials based on size, shape, and density, they reduce the need for additional processing steps, leading to faster and more streamlined operations. In the case of waste management and recycling, this efficiency translates to reduced environmental impact, as more materials can be diverted from landfills and repurposed for reuse.

Limitations and Considerations

Despite their many benefits, trommel screens do have limitations. One of the main challenges is that the rotating drum can become clogged with wet, sticky materials, such as mud or clay, which reduces the efficiency of the separation process. Regular cleaning and maintenance are required to prevent blockages and ensure the machine operates at peak performance. Additionally, trommel screens may not be as effective at separating materials with similar sizes but different shapes or densities, such as shredded plastics or textiles.

Conclusion

Trommel screens play a crucial role in the separation of materials by size, shape, and density. Their widespread application in industries such as municipal waste processing, recycling, composting, and mining highlights their versatility and efficiency. By improving the quality of separated materials and enhancing processing speed, trommel screens contribute to both economic savings and environmental sustainability. As industries continue to evolve and seek more efficient ways to process waste, the importance of trommel screens in promoting responsible resource management will only grow.

-

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote -

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote -

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

-

2023-01-13Bag OpenerBag opener or bag opener system is a mechanical device used to automatically open and empty bags containing bulk materials. This system is commonly used in indu...

-

2024-07-10msw trommel screen for waste recycling machineThis equipment is suitable for the particle classification process in all walks of life:The equipment is simple, easy to operate,and can be operated with a larg...

-

2023-01-12Disc ScreenDisc screen, also known as a disc scalping screen, is a mechanical device used to separate materials based on size. It is commonly used in industries such as wa...

-

2023-01-12Vibrating ScreenVibrating screen is a mechanical device used to separate materials into different sizes and grades by vibrating them through a mesh or screen. This equipment is...

-

2024-07-16Drum screen garbage processing machine for msw recyclingManaging municipal solid waste (MSW) efficiently is crucial for urban areas. Drum screen garbage processing machines are a game-changer in this field. They ensu...