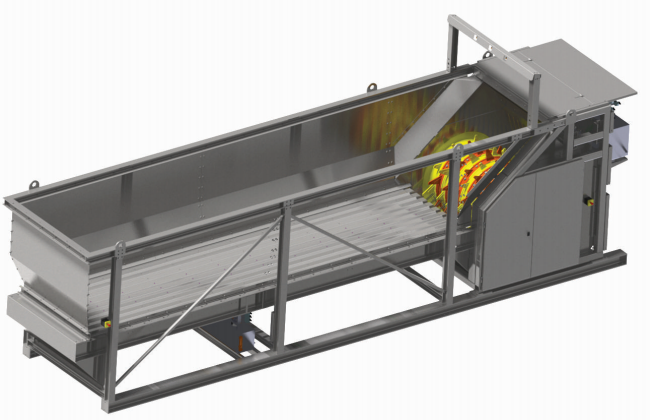

BAG OPENERS

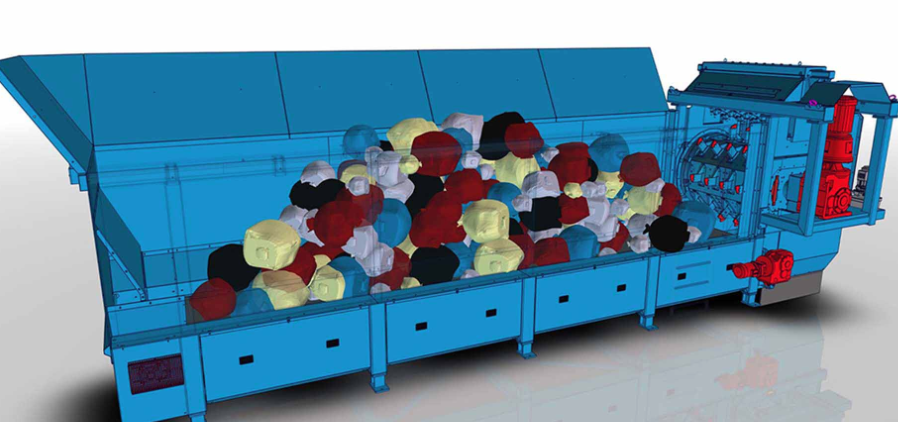

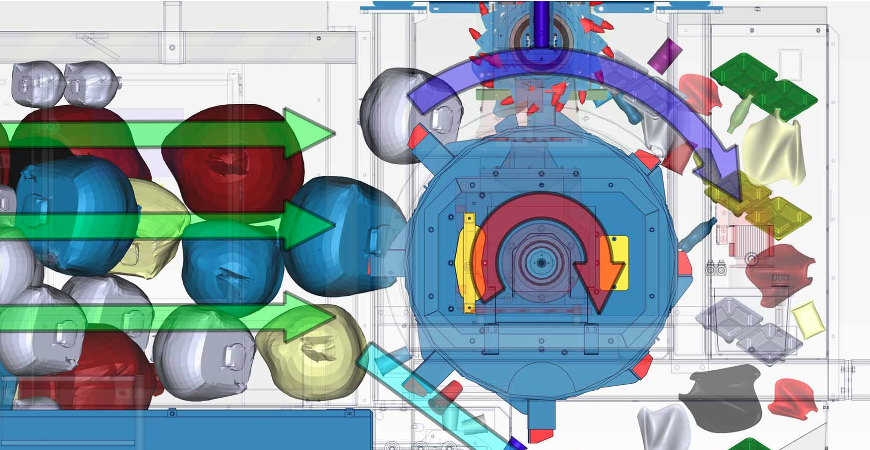

Bag openers working principle is based on squeezing and ripping the waste between knives located on a rotating drum and a set of movable knives. The heavy-duty chain conveyor located in the feeding section allows both dosing the material and storing material for a time interval. Another advantage of the bag openers is, the machine does not shred the waste so, recyclable quantity does not affected by the machine. We provide bag openers in various capacities based on your demands.

This robust machine is extremely suitable to open bags efficiently. Characteristic for the bag opener are the simplicity and

efficiency whereby the consumer and maintenance costs are being limited to a minimum.

These bag openers are very powerful to be installed at the head of treatment plants for municipal solid waste. They are

characterized by a high reliability thanks to a treatment capacity and to couples of considerable magnitude.

The blades of these machines are made of alloy steel and wear. Their shape, thickness, and number of knives is defined in function of the material to be treated. The use of these machines is indicated for: municipal solid waste, waste from waste collection.

Different from other bag openers, this bag opener is designed to be also able to handle more difficult material like wood or WEEE that normally could be inside the MSW material stream. (For this purpose a full size shredder is normally used with a higher power consumption)

1. Virtually 100% opening and emptying of the plastic bags

2.Dismantling for electric appliances

3.Perforation of PET bottles and plastic containers

4. Dewiring of bales

| MB1600 | MB2000 | |

| Capacity | 30tons/h | 45tons/h |

| Bunker Volume | 20m³ | 25m³ |

| Rotor Diameter | 750*1580 | 750*1980 |

| Hydraulic Motor | 22kw | 30kw |

| Rotor | 1580mm | 1980mm |

-

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote -

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote -

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

-

2024-06-06Drum Screen For Composting PlantDrum screen, also known as a rotary drum screen or trommel screen, is an essential piece of equipment used in composting plants for the separation of compost ma...

-

2024-04-13Wobbler FeederWobbler feeder is a type of feeding equipment that uses rotating elliptical bars, known as wobblers, to separate materials based on size and type before they re...

-

2025-04-21Compact Copper Cable Granulator MachineThe compact copper cable granulator machine is a device used to recycle waste wires and cables. It separates the copper wire from the plastic sheath by crushing...

-

2024-04-13Vibrating FeederA vibrating feeder is a mechanical device used to convey materials, typically in bulk, from one location to another in a controlled manner. This equipment is co...

-

2023-01-12Double-Shaft ShredderThe Double-shaft shredder is a widely used industrial shredder that efficiently processes various mixed waste materials, such as construction waste, industrial ...