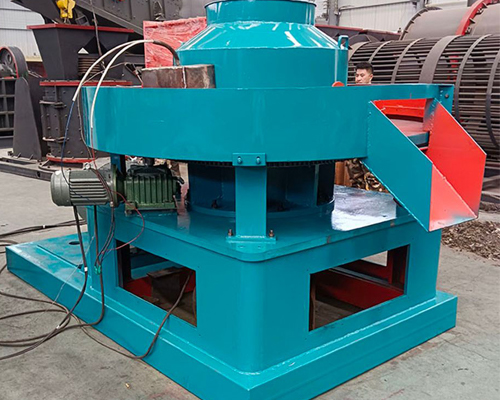

The Production Process and Working Principle of Biomass RDF Rod Making Machine

1). We can discuss the technical details of the equipment, line integration, and possible challenges and solutions in more depth. Here are some key points:

2). Technical features

1. Efficient processing capacity: Modern RDF rod making machines can process large amounts of waste raw materials with high efficiency, ensuring continuous and stable production.

2. Customized design: According to your specific needs, the design of the machine can be adjusted to adapt to different types of waste materials, including municipal solid waste, industrial waste, etc.

3. High-quality output: By accurately controlling the temperature, pressure and material mixing ratio, the output RDF rods have good combustion performance and consistency.

4. Easy maintenance and cleaning: Considering the need for long-term operation, many models adopt a modular design to facilitate daily inspection and replacement of parts.

3). Line integration

1. Pretreatment system: including crushers, magnetic separators, air separators, etc., used to remove non-combustible materials and adjust the size of raw materials.

2. Drying device: reduce the moisture content of raw materials to a suitable level and increase the energy density of the final product.

3. Mixing/mixing unit: ensure that all ingredients are evenly distributed, and sometimes adhesives are added to enhance structural stability.

4. Extrusion molding machine: the core part, responsible for pressing the mixed materials into shape.

5. Cooling and packaging line: the finished products are packaged and stored after natural or forced cooling.

4). Challenges and suggestions

1. Raw material diversity management: due to the wide variety and great changes in the input garbage, a flexible and efficient classification and screening mechanism needs to be established.

2. Environmental compliance: it is very important to comply with local laws and regulations on exhaust emissions, noise control, etc.; consider installing corresponding purification facilities.

3. Cost-benefit analysis: although the initial investment is high, from a long-term perspective, using RDF as an energy source often brings significant cost savings. Therefore, financial feasibility should be carefully evaluated in the project planning stage.

4. Market acceptance: actively promoting the advantages of RDF and finding a stable and reliable buyer group is crucial to the success of the project.

5).Parameter:

Model | Power(KW) | Capacity(T/H) | Mold quantity | Roll quantity | Over dimension(MM) |

9JK-2600 | 75 | 1-2 | 52 | 2 | 2647*2100*1900 |

9JK-3500 | 110 | 2-3 | 72 | 2 | 3250*2600*2000 |

9JK-4500 | 132 | 3-4 | 88 | 2 | 3350*2800*2200 |

9JK-5000 | 160 | 4-5 | 100 | 2 | 3000*2300*2000 |

9JK-5500 | 160 | 4-5 | 102 | 2 | 3000*2400*2000 |

9JK-6500 | 200 | 4-5 | 120 | 3 | 4400*2970*2495 |

-

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote -

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote -

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

-

2024-08-22Medical waste shredderWorking Principle:Feeding Mechanism: Medical waste is fed into the shredder through a hopper or chute. The feeding mechanism ensures that the waste is introduce...

-

2024-06-11Optimize Your Waste Management Today with Our Advanced Drum ScreensUnderstanding the Mechanism and Optimization of Drum Screens for Waste Management

-

2023-01-12Disc ScreenDisc screen, also known as a disc scalping screen, is a mechanical device used to separate materials based on size. It is commonly used in industries such as wa...

-

2025-03-03Mini Copper Wire GranulatorThe copper wire granulator machine is a device specially used to process waste wires and cables. Its main function is to separate the copper and plastic in the ...

-

2023-01-13Bag OpenerBag opener or bag opener system is a mechanical device used to automatically open and empty bags containing bulk materials. This system is commonly used in indu...