Bouncing Screen Ballistic Separator Sorting 2d Materials And 3d Materials Ballistic Separator

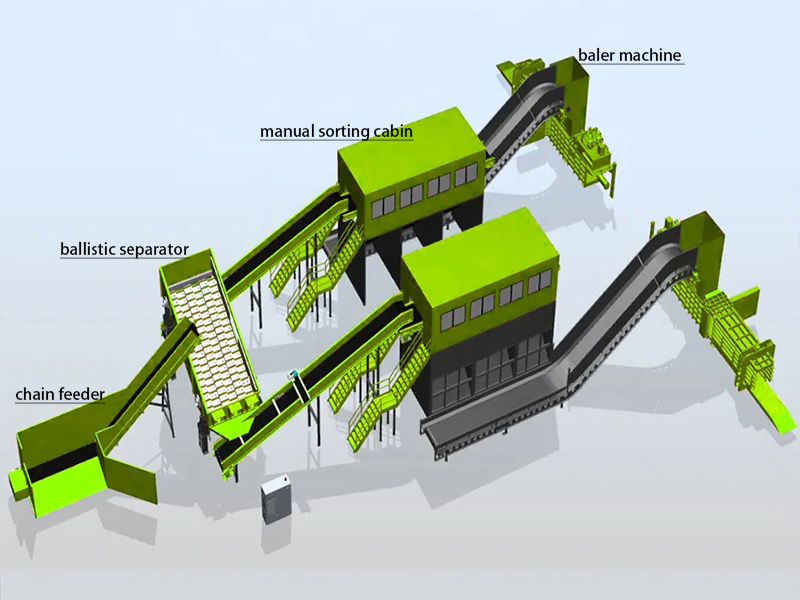

Ballistic separators are placed upstream of sorting plants

and allow you to make the separation of the treated materials

by exploiting the different physical properties which they own.

They have the function of separating the feed stream into

three streams based on the technological principle according

to which the separation of the individual parts placed in a

current of fall takes place according to the different flight curves.

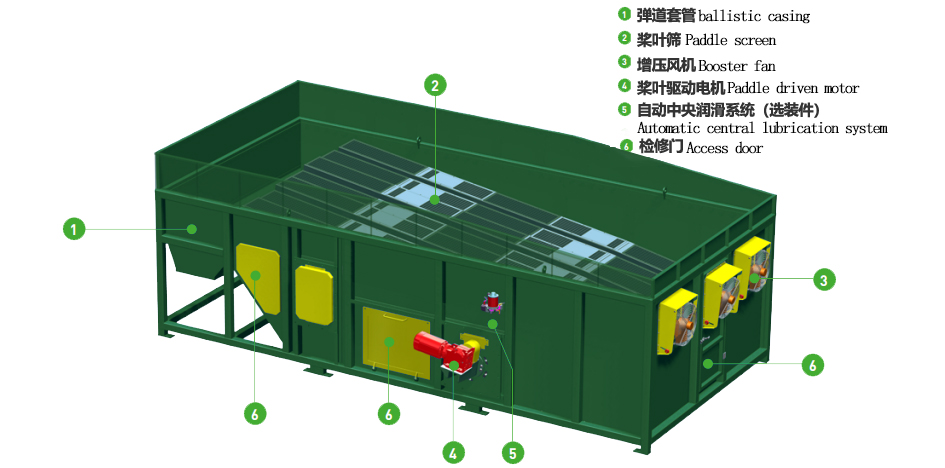

The fed material falls on an inclined bottom and rotating,

by the rotational movement, transmits a pulse and generates

a movement of flight contrary of the individual parts;

at this stage the individual parts behave differently;

light fractions (flat and thin), such as paper, cardboard medium

sized, plastic film, textiles and so on, are thrown upwards

along the trajectories flat and low and transported by the rotary

movement of the base towards the top of machine,

in the direction of the upper hopper arranged to light fractions;

heavy fractions (cubic – solid) are thrown upwards by the

movement of the bottom and flow from the inclined position

of the same in a position of flight directed downwards

of the machine where is located the discharge hopper.

This screening process therefore generates three fractions:

the fraction sieved, the light fraction and the heavy fraction

which are then conveyed to the subsequent steps of the

selection process

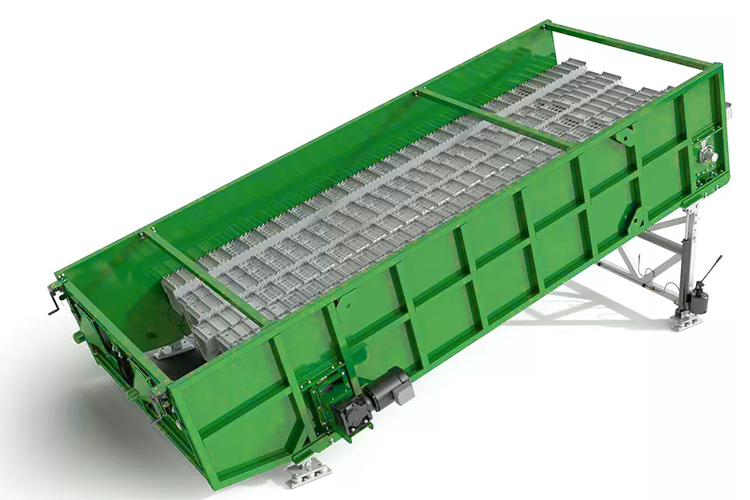

| BS04 | BS06 | BS08 | BS10 | BS12 | |

| Paddy Number | 4 | 4 - 6 | 6 - 8 | 6 - 8 | 6 - 10 |

| Paddle length | 5.5m | 5.5m | 5.5m | 5.5m | 5.5m |

| Angle adjustment | 0 – 25° | 0 – 25° | 0 – 25° | 0 – 25° | 0 – 25° |

| Sieve hole size | 20-80 mm | 30-80 mm | 30-80 mm | 30-80 mm | 30-80 mm |

| Fan Number | 2 - 4 | 2 - 4 | 2- 4 | 2 - 4 | 2 - 4 |

| Power | 5.5kw | 7.5kw | 11kw - 15kw | 11kw -18.5kw | 22kw |

| Throughput | 0-30 m³/h | 30-50 m³/h | 50-70 m³/h | 70-90 m³/h | 90-120 m³/h |

-

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote -

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote -

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

-

2024-04-13Vibrating FeederA vibrating feeder is a mechanical device used to convey materials, typically in bulk, from one location to another in a controlled manner. This equipment is co...

-

2023-01-12Waste FeederWaste feeder was specially designed to optimize municipal solid waste sorting systems. The Drum Feeder ensures that your sorting system, baler or shredder has a...

-

2023-01-18Metal BalerMetal baler, specifically a hydraulic metal baler, is a machine designed to compress scrap metal into dense, manageable bales. This equipment is widely used in ...

-

2024-05-18Spring Cone CrusherSpring cone crushers are generally used in the medium and fine crushing links of mine crushing, and are mainly used in the secondary crushing and tertiary crush...

-

2023-01-12Horizontal Semi-Auto Hydraulic BalerSemi automatic balers are used across the logistics, recycling and manufacturing sectors to process large volumes of waste materials such as cardboard, film, pa...