An Innovative Solution for Efficient Material Handling

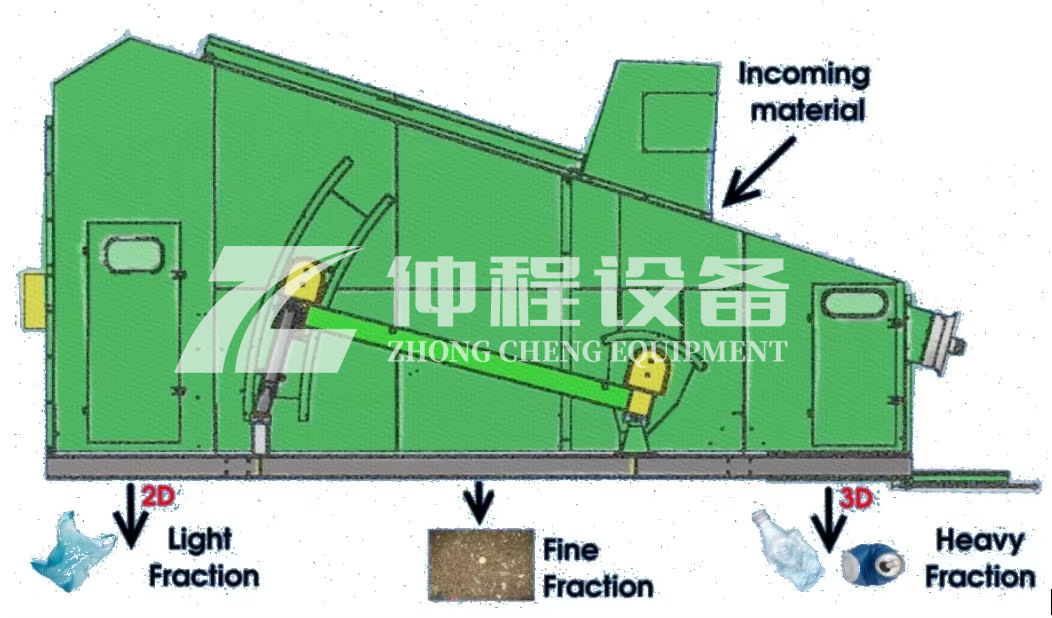

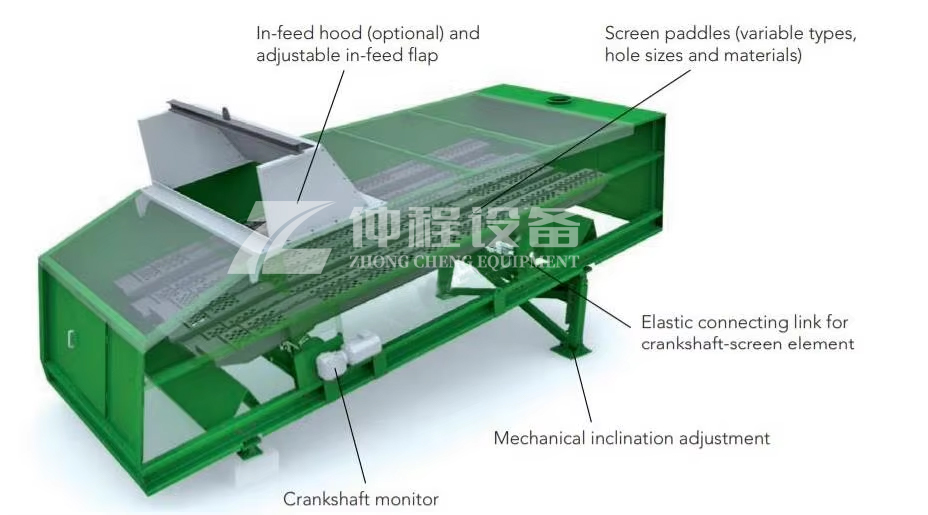

Working Principle

A bouncy sieve, also known as a vibrating screen or jumping screen, is a mechanical device used for material separation. Its basic working principle involves using vibrations generated by a motor to cause the material to bounce on a screen mesh. This bouncing action helps to separate the material into different sizes based on their particle dimensions. The vibrations are typically controlled to ensure optimal screening efficiency and to prevent clogging of the screen.

Development Process

The development of the bouncy sieve has evolved over several decades, driven by the need for more efficient and reliable material handling solutions in various industries. Initially, simple mechanical sieves were used, which required manual operation and had limited capacity. With advancements in technology, electric motors and vibratory systems were introduced to automate the screening process.

- Early Mechanical Sieves: These were basic devices used primarily in agriculture and mining to separate grains and ores.

- Introduction of Electric Motors: In the mid-20th century, electric motors were integrated into sieves, allowing for continuous and automated operation.

- Advanced Vibratory Systems: Modern bouncy sieves feature sophisticated vibratory systems that can be adjusted for different materials and particle sizes, enhancing their versatility and efficiency.

Digital Control Systems: Recent developments include the integration of digital control systems that monitor and adjust the sieve's performance in real-time, further optimizing the screening process.

Materials Handled

Bouncy sieves are capable of handling a wide range of materials across various industries. Some common materials include:

- Minerals and Ores: Used in mining to separate different grades of minerals and ores.

- Grains and Seeds: Common in agriculture for sorting and cleaning seeds and grains.

- Plastics and Recyclables: Used in recycling facilities to separate different types of plastics and other recyclable materials.

- Construction Materials: Used in construction to screen sand, gravel, and other aggregates.

Chemical Products: Used in chemical processing to separate powders and granules.

Advantages

- High Efficiency: Bouncy sieves can process large volumes of material quickly and accurately, significantly improving productivity.

- Versatility: They can be configured to handle a variety of materials and particle sizes, making them suitable for multiple applications.

- Reduced Downtime: The dynamic vibration system minimizes the risk of clogging and reduces the need for frequent maintenance.

- Cost-Effective: By increasing efficiency and reducing waste, bouncy sieves help lower overall operating costs.

- Ergonomic Design: Modern bouncy sieves are designed with operator safety and ease of use in mind, featuring ergonomic layouts and advanced safety features.

- Environmental Benefits: Efficient material separation can lead to reduced waste and better resource utilization, contributing to environmental sustainability.

Application Industries

- Mining and Mineral Processing: Bouncy sieves are essential for separating and grading minerals and ores, improving the quality of the final product.

- Agriculture: Used for cleaning and sorting seeds, grains, and other agricultural products, ensuring high-quality output.

- Recycling: Vital in recycling facilities for separating different types of materials, such as plastics, metals, and paper.

- Construction: Used for screening sand, gravel, and other construction materials, ensuring consistent quality and size.

- Chemical Industry: Used in the production of chemicals to separate powders and granules, maintaining product purity and consistency.

Food Processing: Used for sorting and grading food products, ensuring they meet quality and safety standards.

| Model | Dimension(mm) | power(kw) | Capacity(t/h) |

| 1240 | 1.2m*4m | 5.5kw | 30 |

| 2060 | 2m*6m | 15kw | 150 |

-

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote -

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote -

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

-

2023-01-12Waste Baler For MSWHigh density solid waste balers are the final step before sending waste to landfill. Horizontal balers designed and manufactured for this difficult job and prov...

-

2023-01-12Double-Shaft ShredderThe Double-shaft shredder is a widely used industrial shredder that efficiently processes various mixed waste materials, such as construction waste, industrial ...

-

2025-04-21Compact Copper Cable Granulator MachineThe compact copper cable granulator machine is a device used to recycle waste wires and cables. It separates the copper wire from the plastic sheath by crushing...

-

2024-05-29Landfill stale garbage screening projectAfter communicating with our domestic customers in Shandong Province, we learned that he needed to dispose of the garbage in the landfill through excavation, sc...

-

2024-06-20Wind Separator Technology for Lightweight Materials in Urban Solid Wastewind separator, also known as air separation, is a sophisticated and efficient method of sorting that utilizes air as the separating medium.