breakdown of the two different types of magnetic separators

A magnetic separator in a waste sorting system is a device designed to separate magnetic materials

from non-magnetic materials in a waste stream. It uses a magnetic field to attract and remove ferrous

(iron-containing) materials, such as steel, iron, and other magnetic metals, from the rest of the waste.

How it works:

Magnetic Field Generation: The separator typically consists of a magnet or a series of magnets

(either permanent magnets or electromagnets) that generate a strong magnetic field.

Separation Process: As waste materials pass through the system (often on a conveyor belt), the

magnetic field attracts and pulls ferrous materials toward it, while non-ferrous materials (such as plastics,

glass, and non-metallic waste) continue to move along the conveyor belt.

Collection: The ferrous materials are then removed by a mechanical device such as a scraper, or they

may fall into a designated collection bin.

Applications in Waste Sorting:

Recycling: Magnetic separators are commonly used in recycling centers to extract metal components from

mixed waste streams like electronic waste, automotive scrap, and municipal solid waste.

E-waste Processing: In electronic waste recycling, magnetic separators help in recovering metals like iron

and steel from discarded electronics.

Construction and Demolition Waste: They are also used in construction and demolition debris recycling

to separate steel or iron components, such as nails, bolts, and rebar.

Waste-to-Energy Plants: In waste-to-energy facilities, they ensure that ferrous metals are removed before

waste is incinerated or processed further.

Types of Magnetic Separators:

Permanent Magnetic Separators: These use permanent magnets to create a magnetic field and are used

in applications where a constant magnetic field is needed.

Electromagnetic Separators: These use an electric current to generate a magnetic field, which can be turned

on or off. They are more flexible and can be adjusted depending on the specific needs of the waste stream.

Magnetic Drum Separators: A rotating drum with a magnetic field that attracts magnetic materials as the

waste passes over it.

Overband Magnets: These are suspended above a conveyor belt and remove ferrous materials as the waste

moves underneath them.

Benefits:

- Efficiency: Helps in recovering valuable metals for reuse or recycling.

- Cost-Effective: Saves costs related to metal disposal and reduces contamination in non-metal waste streams.

Environmental Impact: By separating and recovering metals, magnetic separators reduce landfill waste

and support resource conservation.

Overall, magnetic separators are essential in waste sorting systems as they improve recycling rates and contribute

to the reduction of waste going to landfills.

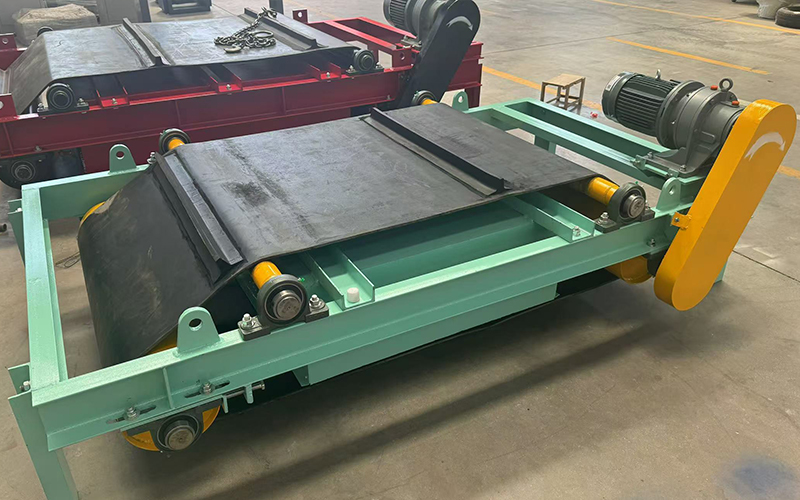

Here’s a breakdown of the two different types of magnetic separators you have:

permanent type and electromagnetic type.

1. Permanent Magnetic Separator

A permanent magnetic separator uses permanent magnets to create a magnetic field. These magnets are typically

made from materials such as neodymium-iron-boron (NdFeB) or ferrite, which have a constant magnetic strength

and do not require an external power source to generate the magnetic field.

Key Features:

No Power Supply Needed: Since the magnets are permanent, they don’t need electricity to maintain the magnetic field.

Low Maintenance: Because there are no moving parts or power supplies to maintain, they require minimal maintenance.

Long-Lasting: The permanent magnets are durable and have a long lifespan.

Simple Operation: These systems are straightforward to install and operate, making them ideal for continuous operations.

Advantages:

Cost-Effective: No electricity costs are involved, which can make these systems more economical in the long term.

Environmentally Friendly: As they don’t require power, permanent magnets are energy-efficient and contribute

to sustainability.

Reliability: They are generally more reliable because there are fewer components that could fail.

Common Uses:

Separating ferrous metals from waste streams in recycling, such as plastics or municipal solid waste.

Removing magnetic particles from industrial processes like cement manufacturing, food processing, or mining.

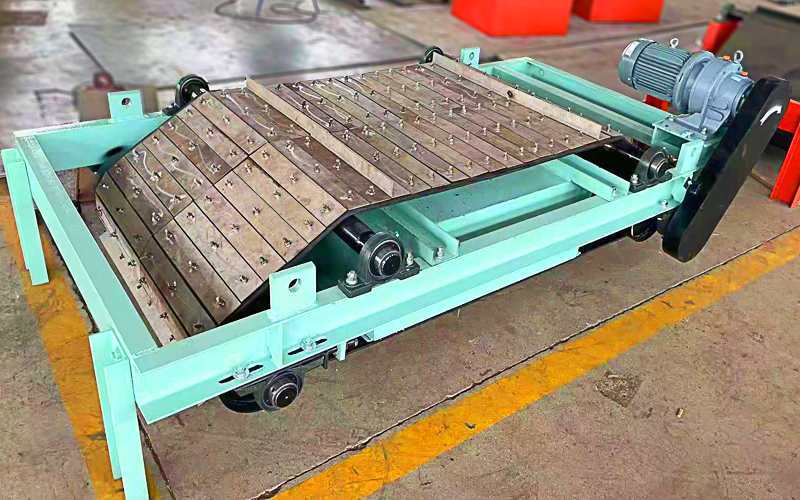

2. Electromagnetic Separator

An electromagnetic separator uses an electromagnet to generate a magnetic field. This magnet is powered by an

electric current that flows through a coil of wire, producing a magnetic field. The strength of the magnetic field can

be adjusted by controlling the electrical current.

Key Features:

Adjustable Magnetic Field: The strength of the magnetic field can be increased or decreased depending on the

needs of the material being processed.

Requires Power Supply: Unlike permanent magnets, electromagnetic separators need a continuous power

supply to generate the magnetic field.

Versatile: These separators can be designed to handle a variety of waste streams with different magnetic

properties.

On/Off Capability: The magnetic field can be turned off when not needed, which can be useful in certain

applications.

Advantages:

Customizable: The ability to adjust the magnetic field strength allows electromagnetic separators to be tailored

to specific applications.

Greater Power: Electromagnetic separators can generate much stronger magnetic fields than permanent types,

making them ideal for handling heavier or more difficult-to-separate ferrous materials.

Precise Control: Since the magnetic field can be controlled, it is easier to adjust the system for different types

of materials or varying waste loads.

Common Uses:

Separating ferrous metals in more complex or high-volume systems, such as those found in scrap metal

processing, mining, and large-scale recycling operations.

Used in industries where precise control over the magnetic field is needed, such as in the food processing

or pharmaceutical industries to prevent metal contamination.

Both types of magnetic separators have their unique benefits depending on the application and materials being

processed. Permanent magnets are typically preferred for simpler, low-cost operations, while electromagnetic

separators offer more flexibility and power for specialized or high-volume processes.

Main parameters sheet :

| model | Width(mm) | Hanging height (mm) | magnetic field strengt h(≥ mT) | power (kw) |

| DD-5 | 500 | 150 | 60 | 1.5 |

| DD-6 | 600 | 175 | 60 | 1.5 |

| DD-6.5 | 650 | 200 | 70 | 2.2 |

| DD-8 | 800 | 250 | 70 | 2.2 |

-

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote -

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote -

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

-

2024-06-20Wind Separator Technology for Lightweight Materials in Urban Solid Wastewind separator, also known as air separation, is a sophisticated and efficient method of sorting that utilizes air as the separating medium.

-

2024-08-28Scrap rubber product shredderThe shredder of waste rubber products not only helps to reduce environmental pollution, but also improves the reuse rate of waste rubber, which is one of the im...

-

2024-08-12Wood Pallet ShredderConsiderations When Choosing a Wood Pallet Shredder:Material Type: Different wood types may require specific configurations or materials of construction.Output ...

-

2024-05-29Landfill stale garbage screening projectAfter communicating with our domestic customers in Shandong Province, we learned that he needed to dispose of the garbage in the landfill through excavation, sc...

-

2024-05-20Mobile Impact Crusher PlantThe mobile impact crusher plant is a kind of crushing equipment based on a mobile platform. It uses an impact crusher as the host machine and is usually equippe...