Bounce Screen: An Innovative Solution for Material Separation

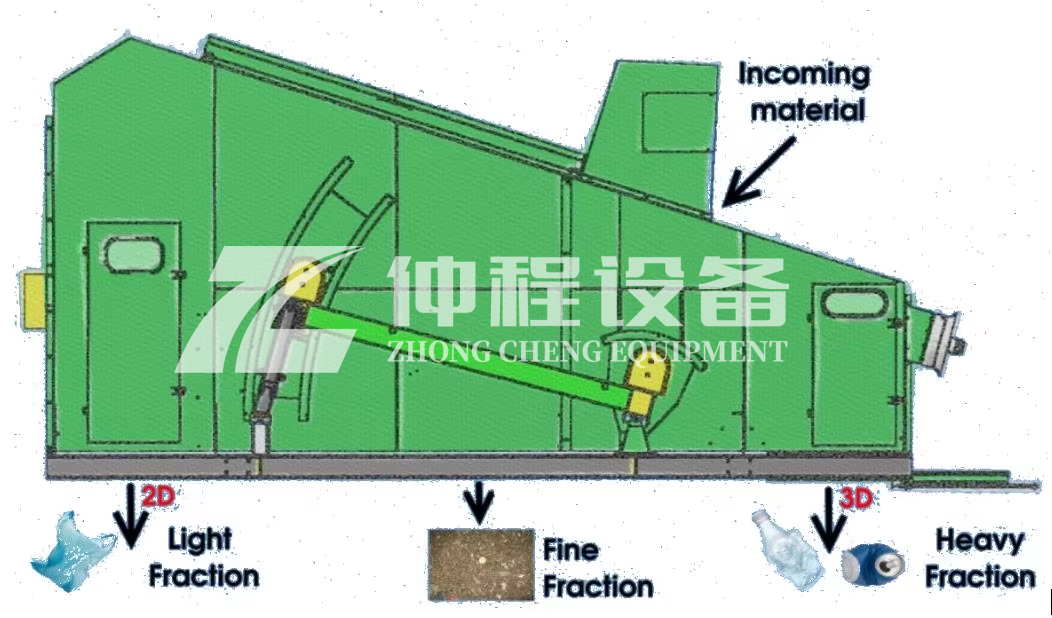

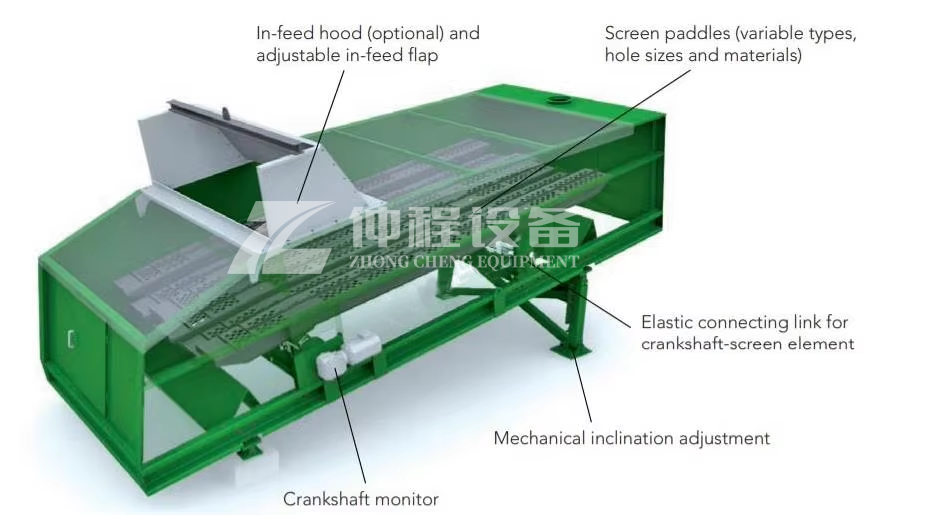

Working PrincipleThe bounce screen operates by conveying material along a sloped surface while simultaneously subjecting it to vertical and horizontal movements. The screen itself is flexible or has a unique design that allows it to oscillate, causing the material to jump or bounce as it moves across the surface. This action helps separate the material into different size fractions as smaller particles fall through the openings in the screen, while larger particles continue to move along the surface until they are discharged.

Advantages

- High Efficiency: The bouncing action increases the probability of particles contacting the screen opening, potentially leading to higher throughput rates.

- Reduced Screen Blockage: The movement of the screen can help prevent clogging and maintain open screen area.

- Versatility: Can be used for wet or dry screening applications.

- Reduced Noise Levels: Some designs may operate more quietly compared to traditional vibrating screens.

Energy Efficiency: Might require less energy due to the unique motion that aids in particle separation.

ProductsBounce screens can be used for a variety of products including but not limited to:

- Coal

- Ores

- Gravel

- Sand

- Wood chips

- Biomass materials

Recycled materials

IndustriesBounce screens find application in several industries such as:

- Mining and mineral processing

- Coal preparation plants

- Aggregate production

- Recycling facilities

- Wood processing

Food processing (though specialized food-grade versions would be required)

In English, you might introduce the bounce screen as follows:

"The bounce screen, a specialized screening device, functions by conveying materials over a sloping, flexible surface that induces both vertical and horizontal movement. This mechanism facilitates the separation of materials according to their sizes, with finer particles passing through the screen apertures while larger particles are carried downstream. This equipment is favored for its high efficiency, reduced risk of blockage, and suitability for diverse applications ranging from mineral extraction to recycling processes. Industries that benefit from the use of bounce screens include mining, construction material processing, and waste management sectors."

Please note that specific models and designs can vary significantly, so the characteristics described here should be considered general rather than definitive for all types of bounce screens.

-

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote -

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote -

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

-

2024-04-13Vibrating FeederA vibrating feeder is a mechanical device used to convey materials, typically in bulk, from one location to another in a controlled manner. This equipment is co...

-

2024-06-09Drum Screen RecyclingDrum screen machines are primarily used for material screening, helping to sort and recycle municipal solid waste and screen landfill waste. Their efficiency an...

-

2024-06-11Optimize Your Waste Management Today with Our Advanced Drum ScreensUnderstanding the Mechanism and Optimization of Drum Screens for Waste Management

-

2024-08-07Efficient Material Separation with Bounce ScreensThe ballistic separator is an important equipment with separation function designed for the sorting of inorganic particles in the coarsely crushed waste.

-

2024-05-18Mobile Jaw Crusher PlantMobile jaw crushing station is a novel rock crushing equipment, also known as mobile crushing station. The purpose of its design concept is to stand from the cu...