Let's get to know the hydraulic coarse crusher

Talk about the hydraulic coarse crusher

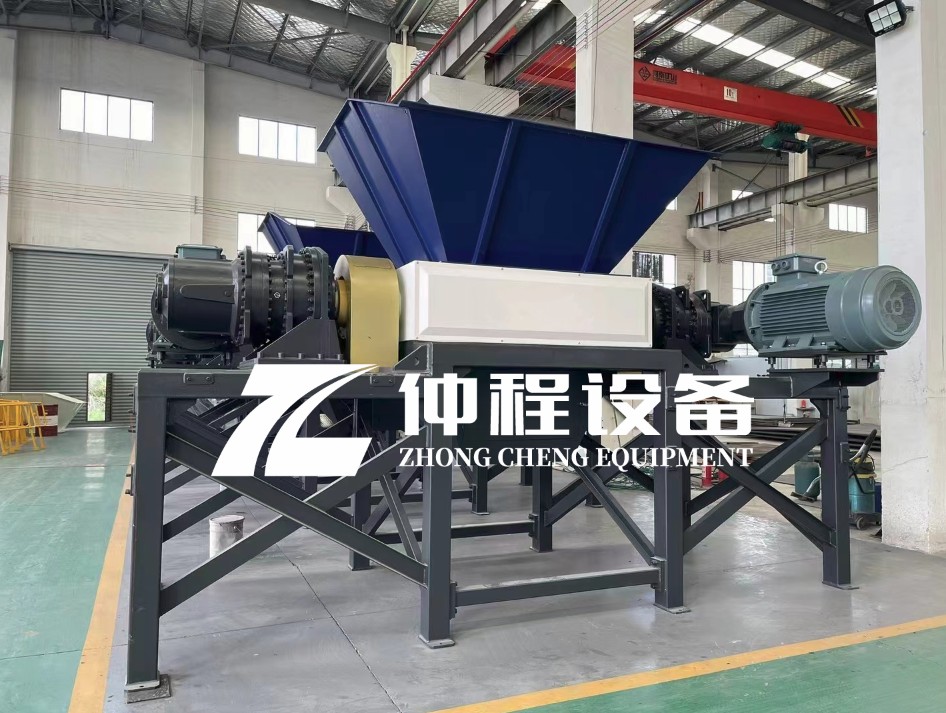

In the field of solid waste disposal, especially in the production line for the treatment of domestic waste, stale waste and decoration waste, the hydraulic coarse crusher, as the core equipment of the first crushing process, plays a pivotal role. Its powerful performance and unique design advantages make it the key to solving the problem of complex material crushing.

The hydraulic coarse crusher has shown excellent adaptability and flexibility with its hydraulic drive system. Whether it is facing domestic waste with complex composition and large volume, or other difficult-to-handle solid waste materials, it can handle it with ease. The hydraulic drive not only gives the equipment the ability to change speed infinitely, but also enables it to frequently perform forward and reverse operations, thereby ensuring the stable operation of the production line and effectively solving many problems in the material disposal process.

In terms of tool material, the equipment uses CrNiMo high-alloy steel imported from Europe, which has excellent wear resistance and impact resistance. The surfacing repair function of the tool further reduces the production cost and extends the service life of the equipment. At the same time, the tool box has been heat-treated as a whole, which not only improves the precision, but also ensures long-term durability and is not easy to deform. This specially designed knife-shaped structure is very suitable for hooking and grabbing large materials for tearing and shearing operations.

In addition, the hydraulic coarse crusher also uses high-strength materials and hardening treatment processes, as well as a specially designed high-torque structure, which provides a solid guarantee for the stable crushing of the equipment. These designs not only improve the crushing efficiency of the equipment, but also ensure the uniformity and fineness of the materials during the crushing process.

| Model | 600 | 800 | 1000 | 1200 | 1400 | 1600 | 1800 |

| Motor(kw) | 11*2 | 18.5*2 | 35*2 | 45*2 | 55*2 | 75*2 | 110*2 |

Reducer | P6-P7 | P7-P8 | P8-P10 | P10-P12 | P11-P13 | P12-P16 | P14-P16 |

| Siemens or other motors, planetary reducers or other reducers can be customized according to customer requirements | |||||||

| Rotation Speed | 8-20rmp | 8-20rmp | 8-15rmp | 8-15rmp | 8-15rmp | 8-12rmp | 8-12rmp |

| Blades Diameter | 220-320 | 260-320 | 260-400 | 400-500 | 400-500 | 500 | 500 |

| Blades material | The material of the blades (55sicr, 5crsi, 9crsi, skd11, m6v, h13) can be customizedaccording to the customer's actual usage | ||||||

| Feeding Size | 1200*900mm | 1400*1000mm | 1600*1200mm | 1800*1300mm | 2000*1300mm | 2200*1700mm | 2400*2000mm |

| The size and appearance of the feeding hopper can be customized according to thecustomer's feeding situation | |||||||

| Weight(kg) | 1800 | 2500 | 3700 | 5500 | 7500 | 9500 | 13000 |

Compared with motor drive, hydraulic drive has more advantages in energy consumption and can achieve more energy-saving operation. At the same time, the overall operation of the hydraulic coarse crusher is smoother, the service life is longer, and it is easy to maintain and maintain. These characteristics make the equipment have broad application prospects and significant market competitiveness in the field of solid waste disposal.

-

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote -

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote -

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

-

2023-01-12Waste Baler For MSWHigh density solid waste balers are the final step before sending waste to landfill. Horizontal balers designed and manufactured for this difficult job and prov...

-

2024-05-18Mobile Jaw Crusher PlantMobile jaw crushing station is a novel rock crushing equipment, also known as mobile crushing station. The purpose of its design concept is to stand from the cu...

-

2024-06-11Optimize Your Waste Management Today with Our Advanced Drum ScreensUnderstanding the Mechanism and Optimization of Drum Screens for Waste Management

-

2024-06-09Drum Screen RecyclingDrum screen machines are primarily used for material screening, helping to sort and recycle municipal solid waste and screen landfill waste. Their efficiency an...

-

2024-08-22Medical waste shredderWorking Principle:Feeding Mechanism: Medical waste is fed into the shredder through a hopper or chute. The feeding mechanism ensures that the waste is introduce...