Innovative Horizontal Hydraulic Baling Press: Revolutionizing Waste Management Efficiency

Introduction:

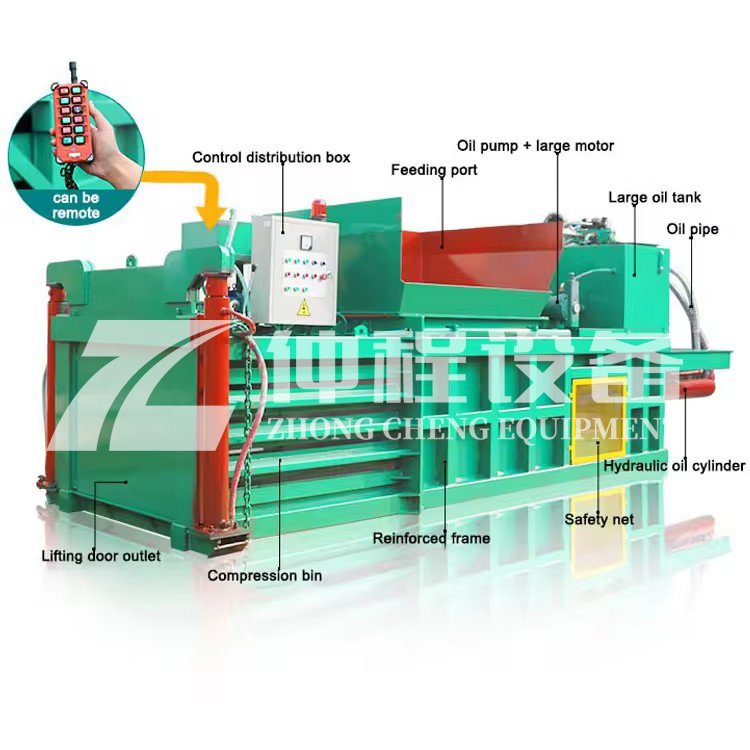

A horizontal hydraulic baling press is a type of machinery used for compressing materials into compact bales. This process facilitates easier handling, storage, and transportation of the compressed materials. The machine is typically powered by a hydraulic system that applies a large force to compress the material.

Working Principle:

The basic working principle of a horizontal hydraulic baling press involves the following steps:

- Material Loading: Loose materials such as paper, cardboard, textiles, plastic bottles, or metal scraps are fed into the machine through an inlet opening.

- Compression: Once inside, a horizontally moving compression plate or plunger powered by hydraulics pushes the material against the walls of the chamber, compacting it under high pressure.

- Bale Formation: When the desired density is reached, the material is tied off using wire, strapping, or another binding method to form a solid bale.

Ejection: After the bale is formed and secured, it is ejected from the machine through an ejection port.

![]()

Advantages:

- Efficiency: Reduces the volume of waste materials, making storage and transport more efficient.

- Cost Savings: Lower transportation costs due to reduced volume and weight of materials being shipped.

- Environmentally Friendly: Promotes recycling by preparing materials in a form that's easier to handle for recycling processes.

- Safety: Improves workplace safety by reducing clutter and the risk of accidents associated with loose materials.

Customization: Can be designed to handle various types of materials and can be customized for specific needs.

![]()

Applicable Industries:

Horizontal hydraulic baling presses find applications across numerous industries, including but not limited to:

- Recycling Centers: For processing recyclable materials like plastics, paper, and metals.

- Manufacturing Plants: To manage waste generated during production processes.

- Warehouses: To compact packaging materials for efficient waste management.

- Supermarkets and Retail Stores: To manage cardboard boxes and other packaging waste.

Logistics and Transportation: To prepare goods for shipping, ensuring they are compact and secure.

By employing these machines, businesses can streamline their waste management practices while contributing positively to environmental sustainability efforts.

-

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote -

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote -

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

-

2023-01-12Double-Shaft ShredderThe Double-shaft shredder is a widely used industrial shredder that efficiently processes various mixed waste materials, such as construction waste, industrial ...

-

2024-08-22Medical waste shredderWorking Principle:Feeding Mechanism: Medical waste is fed into the shredder through a hopper or chute. The feeding mechanism ensures that the waste is introduce...

-

2023-01-12Waste Baler For MSWHigh density solid waste balers are the final step before sending waste to landfill. Horizontal balers designed and manufactured for this difficult job and prov...

-

2024-08-05Hot-sell Coconut Shredderworking principleCoconut shell shredder usually uses the force generated by cone and spiral to evenly squeeze the coconut meat in the grinding chamber between t...

-

2024-06-09Drum Screen RecyclingDrum screen machines are primarily used for material screening, helping to sort and recycle municipal solid waste and screen landfill waste. Their efficiency an...