Long Term Waste Management Strategy

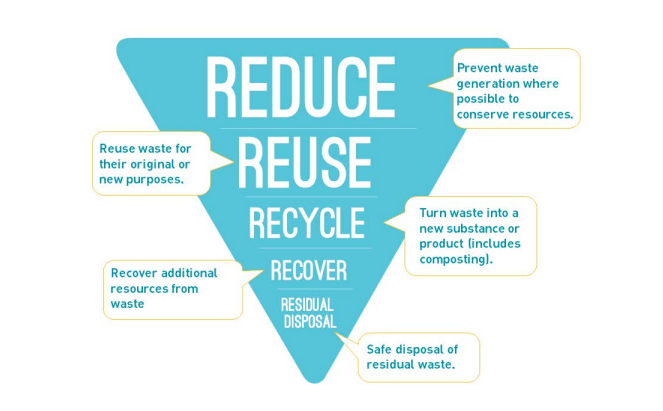

• The new series of 5Rs (Reduce, Reuse, Recycle, Recover, Residual Disposal)options being recommended

through the Waste Strategy has the potential to further extend the life of the landfill.

• A refinement of the projections of material to be received at Landfill.

• A review of current landfill operations has revealed that the settlement rate of materials in the site is occurring

at a greater rate than initially estimated. The rate of settlement is contingent on the composition of the waste and

the analysis suggests that the current rate of settlement will continue.

A Commitment to Prioritizing the Waste Hierarchy through Reduction, Reuse and Recycling

The Waste Strategy places emphasis on waste reduction, reuse and recycling (the 3Rs)activities to promote

the importance of resource conservation and to reduceenvironmental impact.

The recommended waste reduction programs require minimal capital investment and when combined with

education and enforcement have the potential to significantly reduce the amount of material requiring

management by the City,once fully implemented.

The Waste Strategy recommends five new reduction, reuse and recycling focused programs for early implementation

that address food waste reduction, textiles diversion,sharing and reuse opportunities and support community

based waste exchange programs.

Maximizing the Life of Landfill

The development of the Waste Strategy placed a priority on maximizing the life of Landfill by minimizing the

amount of garbage sent for disposal. Factors that have led to updated estimates of the life of Landfill

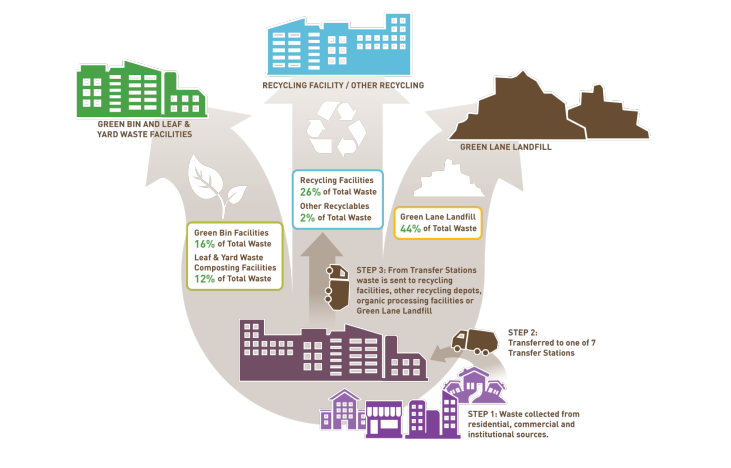

Solid Waste Management System Overview

Municipal solid waste consists of all types of waste generated in the household.

In addition to organic waste such as leftover food, this also includes a wide variety

of recyclable materials. This type of diverse material composition with a correspondingly highly

varied density of between 100 and 300 kg/m3 represents a particular challenge for such plants,

because it simultaneously demands a high degree of plant flexibility and robustness.

Example process description for an automated sorting plant for municipal solid waste with manual re-sorting:

After infeed dosing, the material is separated into different grain sizes according to shape (flat [2D], rolling [3D], screening)

by various screening processes via our trommel screen and ballistic separator machinery.

In order to achieve the maximum possible sorting purity, large-area films are separated from the material flows with the aid of windshifters.

This significantly improves subsequent sorting using near infrared technology (NIR).

In combination with the subsequent magnetic and eddy current process, the desired high output qualities are achieved.

Following manual quality controlling, the material is finally separated into fractions, collected in hopper belts and pressed to reduce volume for storage and transport.

Example process description for a fully automatic municipal solid waste sorting plant:

Here, the waste is initially uniformly fed into the plant via a feed dosing system. Organic constituents, plastic packaging

and cans are separated out by means of screening , as well as magnets. During the next step, we separate the various

polymers and Tetrapak elements into different types of plastic using a special optical recognition matrix. This is followed

by the extraction of paper, as well as non-ferrous metals. The organic fraction is stabilised by means of a biological process

and processed into high-quality compost material. A further option is to use the organic fraction for alternative power generation

in an anaerobic fermentation plant.

-

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote -

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote -

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

-

2023-01-12Waste Baler For MSWHigh density solid waste balers are the final step before sending waste to landfill. Horizontal balers designed and manufactured for this difficult job and prov...

-

2024-06-11Optimize Your Waste Management Today with Our Advanced Drum ScreensUnderstanding the Mechanism and Optimization of Drum Screens for Waste Management

-

2024-07-09Recycling Balers-Safe,Easy-To-Use and affordableThe operating principle of a strapping machine primarily involves the following steps:1.Item Positioning:Firstly, the item to be strapped must be placed accurat...

-

2024-08-22Medical waste shredderWorking Principle:Feeding Mechanism: Medical waste is fed into the shredder through a hopper or chute. The feeding mechanism ensures that the waste is introduce...

-

2023-01-12WindshifterWindshifter (Air Drum Separator ) is the ideal solution for separating all kind of waste types into two fractions, heavy and light. The robust construction and ...