What Is a Solid Waste Management Plan?

What Is a Solid Waste Management Plan?

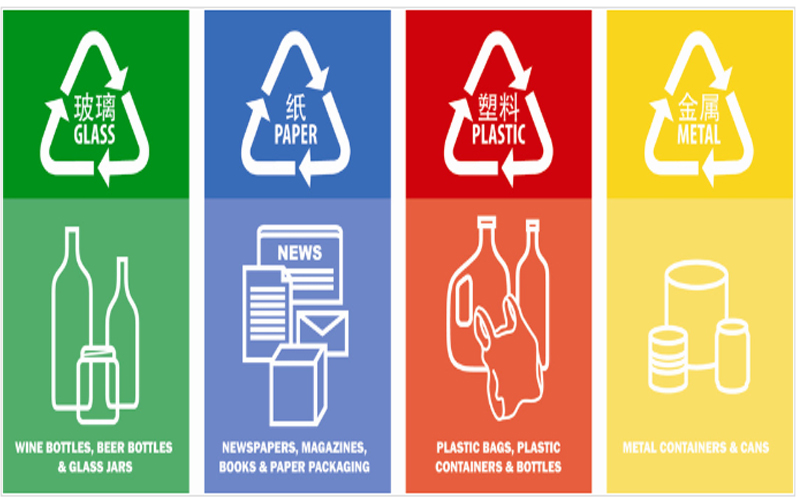

Domestic solid waste, commonly known as trash or garbage (US), refuse or rubbish(UK) is a waste type consisting of

everyday items that are discarded by the public. The organic waste potions consist of food and kitchen waste, yard trimmings

or other garden waste. Inorganic waste consists of paper, corrugated cardboard, plastic, glass, wood, and metal products

such as drink cans.

A basic solid waste management plan typically includes:

• A profile of the tribal community.

• The goals and objectives of the plan.

• An overview of the existing solid waste

management program.

• Solid waste management alternatives,along with a discussion of the issues and uncertainties associated with each alternative.

• The selected alternative, implementation measures, and potential funding sources.

• Any solid waste codes that need to be developed.

Developing Long-Term and Short-Term Goals

Solid waste management is a complex puzzle with many pieces, and it is easy to get sidetracked

in your planning process. Developing goals will help guide your solid waste management planning

and keep you focused on your priorities. Goals also can help you set targets by which your tribe can measure progress.

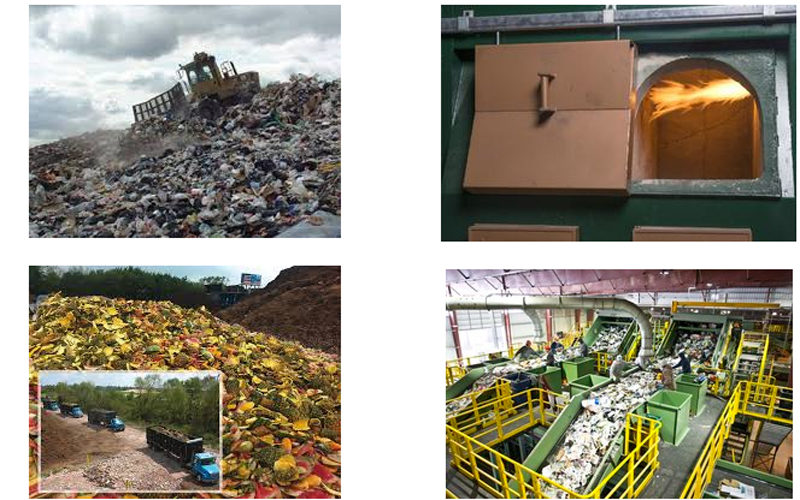

Once the trucks enter the landfill site loaded with Municipal Solid Waste (MSW), the first step is to select and separate

all the materials, which are going to be processed in the waste treatment plant.

Inert materials, also called aggregates or improper materials such as metals, sands, stone, ceramics that cannot be treated

by our processes in the REVALUO plant and that do not have any calorific value are removed. The same applies to a large

part of the water that is in the waste.

Among the materials that are recovered, and to name but a few, we can highlight the recovery of ferrous and other metals

with market prices to be taken into account, such as aluminium and copper. We also obtain glass, paper, cardboard and

other recycled materials.

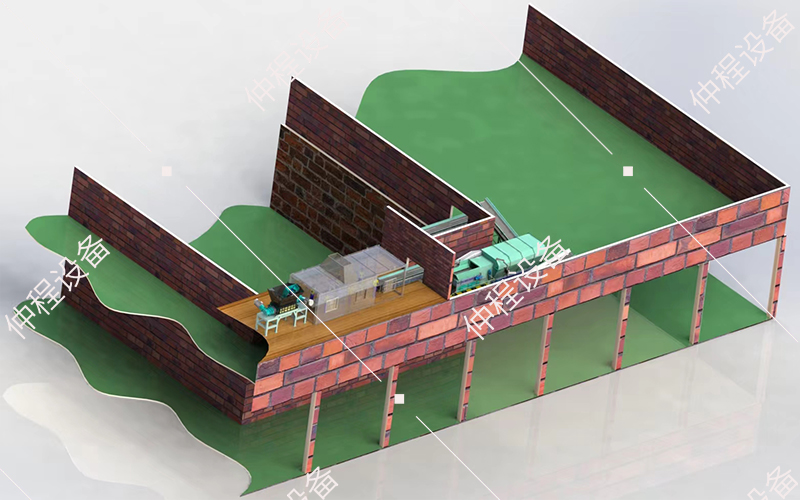

There are two types of solid waste separation, in function of the amount of waste to be treated, the specific purpose of the

treatment plant or module and the labour cost of the country.

In the case of manual sorting, the waste is placed on conveyor belts and people on either side of the conveyor belt

separate and select the type of waste they want.

In the following video you can see how workers separate bottles and plastics in general to be further treated by a

specific plastics treatment module. In that process we will obtain raw bunker fuel with approximately 1% sulphur.

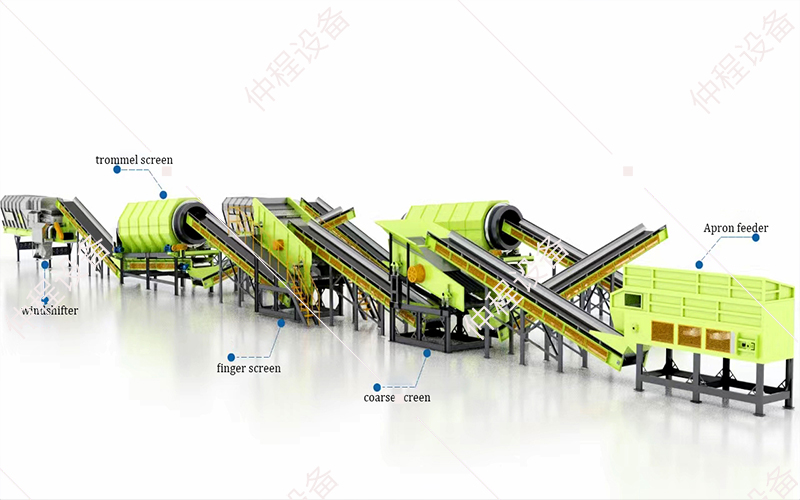

In countries where labour costs are high, specific and specialised machinery is normally used. The work involves

less human capital and the materials are separated through belts, ballistic separators, air separators, decantation

separators, sieving machines, industrial magnets, etc. It requires a higher initial investment, but with a quick ROI.

Regardless of the chosen method of sorting and separation of waste, manual or automatic, the filtered waste passes

through different shredders in the process until reaching the size required by the pelletiser.

-

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote -

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote -

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

-

2024-05-18Spring Cone CrusherSpring cone crushers are generally used in the medium and fine crushing links of mine crushing, and are mainly used in the secondary crushing and tertiary crush...

-

2024-04-13Vibrating FeederA vibrating feeder is a mechanical device used to convey materials, typically in bulk, from one location to another in a controlled manner. This equipment is co...

-

2024-08-07Efficient Material Separation with Bounce ScreensThe ballistic separator is an important equipment with separation function designed for the sorting of inorganic particles in the coarsely crushed waste.

-

2024-08-20A rubber double shaft shredderExamples of Specific Models:GDB Series Biomass Shredder: Although primarily designed for biomass materials, this model can also be configured to handle various ...

-

2023-01-12WindshifterWindshifter (Air Drum Separator ) is the ideal solution for separating all kind of waste types into two fractions, heavy and light. The robust construction and ...