msw trommel screen for waste recycling machine

-

Production Capacity:

by model

-

Applicable Industries:

Demolition waste, stale waste, construction waste sorting recycling

-

Power:

125kw

-

Core Components:

Crankshaft maintenance. Centralised lubrication system.

-

Place of Origin:

Henan, China

- Product Details

- Characteristics

- Working Principle and Application

- Parameters

Advantages of Trommel Screens

The widespread adoption of trommel screens in waste recycling is attributed to their numerous advantages:

Efficiency in Material Separation:

Trommel screens are highly efficient at separating materials based on size. Their rotating drum design ensures continuous and consistent screening, allowing for the processing of large volumes of waste with minimal downtime.Versatility:

The ability to handle a wide range of materials makes trommel screens versatile. They can be used for various types of waste, from household garbage to construction debris, making them a valuable asset in any recycling facility.Low Operating Costs:

Trommel screens have relatively low operating costs compared to other screening technologies. Their simple mechanical design reduces maintenance requirements and operational expenses, making them cost-effective for recycling operations.Durability and Longevity:

Built to withstand harsh working conditions, trommel screens are durable and have a long operational lifespan. This durability translates to reduced replacement costs and long-term reliability for recycling facilities.Environmental Benefits:

By efficiently separating recyclable materials from waste, trommel screens contribute to the reduction of landfill usage and the promotion of recycling. This not only conserves natural resources but also minimizes the environmental impact of waste disposal.

-

01a wide application range

-

02strong and durable

-

03smooth operation

-

04no vibration, low noise

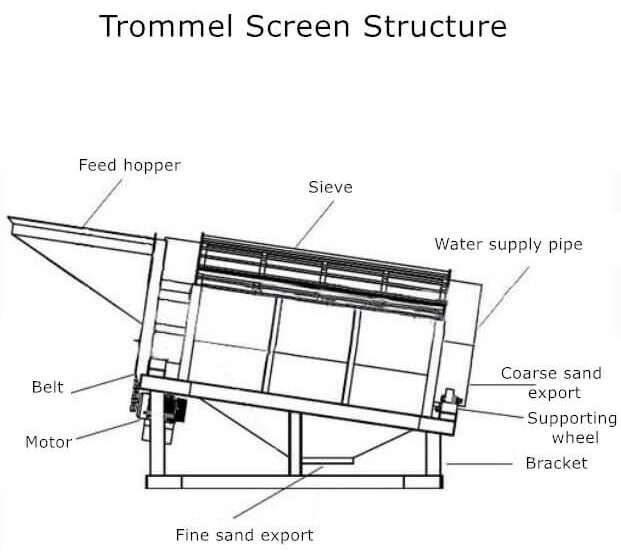

Understanding Trommel Screens

A trommel screen, also known as a rotary screen, is a mechanical screening machine used to separate materials, typically based on size. It consists of a cylindrical drum that is perforated with various-sized holes. As the drum rotates, material is fed into it, and smaller particles pass through the holes, while larger items continue along the length of the drum until they are discharged at the end. This simple yet effective mechanism allows for the efficient separation of different types of waste, facilitating subsequent recycling processes.

Applications in Waste Recycling

Trommel screens are versatile and can be applied to various types of waste, making them indispensable in recycling facilities. Here are some key applications:

Municipal Solid Waste (MSW) Management:

Trommel screens are widely used in the initial stages of MSW processing. They help segregate organic waste from inorganic materials, enhancing the efficiency of composting and anaerobic digestion processes. By separating biodegradable materials, trommel screens contribute to reducing landfill use and promoting organic recycling.Construction and Demolition Waste (C&D):

In the construction and demolition sector, trommel screens play a crucial role in separating aggregates, wood, metals, and other recyclables. This separation not only facilitates the recycling of valuable materials but also reduces the volume of waste sent to landfills, contributing to more sustainable construction practices.Composting Operations:

Trommel screens are essential in composting facilities, where they are used to separate finished compost from oversized materials that require further processing. This ensures the production of high-quality compost, free from contaminants and suitable for agricultural and landscaping applications.Mining and Quarrying:

Although not exclusively a recycling application, trommel screens are also employed in mining and quarrying to separate valuable minerals from waste material. This application highlights the versatility of trommel screens across different industries.

| TS1804 | TS1806 | TS2506 | TS2508 | TS3008 | TS3010 | |

| Length of sieve | 4000mm | 6000mm | 6000mm | 8000mm | 8000mm | 10000mm |

| Diameter | 1800mm | 1800mm | 2500mm | 2500mm | 3000mm | 3000mm |

| Speed | 0-15 rpm | 0-15 rpm | 0-15 rpm | 0-15 rpm | 0-15 rpm | 0-15 rpm |

| Drum inclination | 4°-7° | 4°-7° | 4°-7° | 4°-7° | 4°-7° | 4°-7° |

| Sieve hole size | 10 - 150mm | 10 - 150mm | 10 - 150mm | 10 - 150mm | 10 - 150mm | 10 - 150mm |

| Under sieve stream | 2 or 3 | 2 or 3 | 2 or 3 | 2 or 3 | 2 or 3 | 2 or 3 |

| Power | 11kw | 15kw | 15kw | 18.5kw | 22kw | 30kw |

| Throughput | 10-20m³/h | 20-35m³/h | 35-50m³/h | 50-65m³/h | 65-80m³/h | 80-100m³/h |

-

msw trommel screen for waste recycling machineThis equipment is suitable for the particle classification process in all walks of life:The equipment is simple, easy to operate,and can be operated with a larg...Get Quote

msw trommel screen for waste recycling machineThis equipment is suitable for the particle classification process in all walks of life:The equipment is simple, easy to operate,and can be operated with a larg...Get Quote -

Zhongcheng Air Drum Separator in MSWAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

Zhongcheng Air Drum Separator in MSWAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote -

Optimize Your Waste Management Today with Our Advanced Drum ScreensUnderstanding the Mechanism and Optimization of Drum Screens for Waste ManagementGet Quote

Optimize Your Waste Management Today with Our Advanced Drum ScreensUnderstanding the Mechanism and Optimization of Drum Screens for Waste ManagementGet Quote -

Efficient Material Separation with Bounce ScreensThe ballistic separator is an important equipment with separation function designed for the sorting of inorganic particles in the coarsely crushed waste.Get Quote

Efficient Material Separation with Bounce ScreensThe ballistic separator is an important equipment with separation function designed for the sorting of inorganic particles in the coarsely crushed waste.Get Quote