Horizontal Balers: Efficient Solutions for Material Handling and Waste Management

Working Principle of Horizontal Balers

1. Material Feeding:The process begins when the material to be baled is fed into the baler through an opening at one end. This can be done manually, but in larger industrial settings, conveyor systems are often used to automate the feeding process.

2. Compression:Once the material enters the baler, it is pushed into a compression chamber where a powerful hydraulic ram exerts significant force to compress the material into a dense form. The compression ratio can vary depending on the type of material and the desired density of the bale.

3. Baling:As the material is compressed, it forms a compact bale. In most horizontal balers, once the bale reaches the desired size, it is tied with wire, string, or straps to maintain its shape. This tying process is often automated, with sensors detecting when the bale is ready and triggering the tying mechanism.

4. Ejection:After the bale is securely tied, it is ejected from the baler through an opening at the opposite end. The bale is then ready for handling, storage, or transportation.

Applications of Horizontal Balers

1. Recycling Industry:

- Paper and Cardboard: Horizontal balers are extensively used in recycling centers to compress waste paper and cardboard into manageable bales for easier transportation to paper mills.

- Plastics: They are also used to bale various types of plastic waste, such as PET bottles, HDPE containers, and plastic films, which are then sent for recycling or repurposing.

Metals: Scrap metal, including aluminum cans, steel sheets, and other metal waste, can be compressed into dense bales for efficient handling and recycling.

2. Waste Management:

- Municipal Solid Waste (MSW): Horizontal balers are used in waste management facilities to compress mixed municipal solid waste, reducing the volume of waste and optimizing landfill space.

- Industrial Waste: They are also used to manage and compress industrial waste materials, such as packaging waste, production scraps, and other non-hazardous waste.

3. Agricultural Industry:

- Hay and Straw: Farmers and agricultural operations use horizontal balers to compress hay and straw into bales for storage and distribution.

Crop Residues: Other crop residues, such as corn stalks and wheat straw, can also be baled for various uses, including animal bedding and biofuel production.

4. Manufacturing Industry:

- Packaging Materials: Manufacturers use horizontal balers to compress waste packaging materials, such as corrugated boxes and plastic wrap, for recycling or disposal.

- Production Scraps: In industries like textiles and automotive, horizontal balers help manage and compress production scraps and off-cuts.

Benefits of Using Horizontal Balers

- Volume Reduction: Significantly reduces the volume of materials, making storage and transportation more efficient.

- Cost Savings: Reduces transportation costs and landfill fees by minimizing the volume of waste.

- Environmental Impact: Supports recycling efforts and reduces the environmental footprint of waste management.

- Operational Efficiency: Automates the baling process, increasing productivity and reducing labor costs.

Key Features of Horizontal Balers:

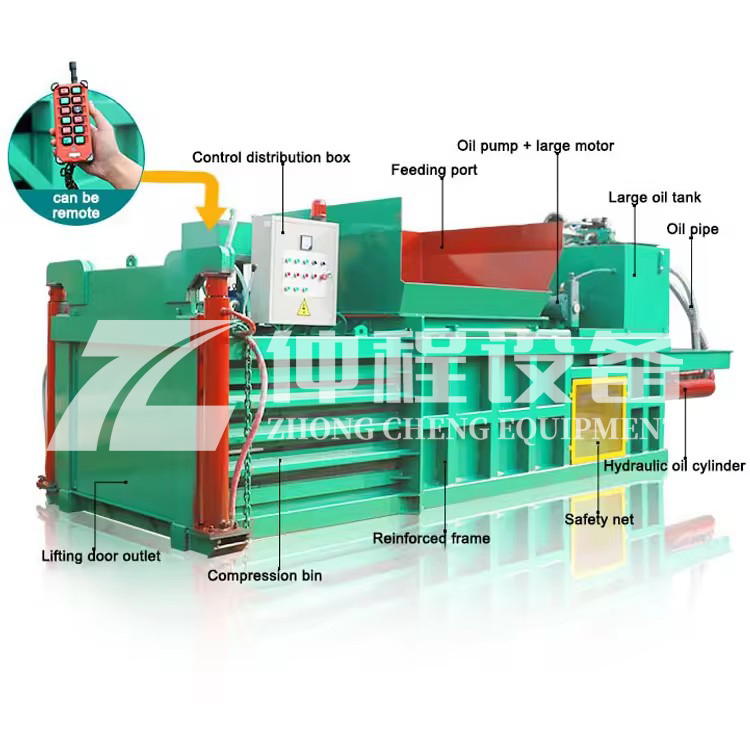

Design: Horizontal balers are typically long and low-profile, allowing materials to be fed into the machine from one end while the compressed bales are ejected from the other side. This design facilitates continuous operation and efficient material flow.

Material Handling: They can process a wide range of materials including paper, cardboard, plastics, metals, and agricultural products like hay and straw. The versatility of these machines makes them suitable for diverse applications.

Compression Mechanism: Equipped with powerful hydraulic systems, horizontal balers exert significant force to compress materials into dense bales. The compression ratio can vary depending on the type of material being processed and the specific requirements of the application.

Automation: Many modern horizontal balers come with automated features such as automatic tying systems that secure the bales with wire or string after they have been compressed. Some models also include sensors and control systems that monitor the baling process and optimize performance.

Capacity and Efficiency: Horizontal balers are available in various sizes and capacities to meet different needs. Larger industrial models can handle high volumes of material and operate continuously, making them ideal for large-scale operations.

Environmental Benefits: By reducing the volume of waste and recyclables, horizontal balers help minimize the environmental impact of waste disposal and promote more sustainable practices in material handling.

Safety Features: To ensure safe operation, these machines often include safety guards, emergency stop buttons, and other protective measures to prevent accidents during use.

Maintenance: Regular maintenance is crucial for keeping a horizontal baler in good working condition. This includes checking hydraulic fluid levels, inspecting belts and bearings, and ensuring that all moving parts are properly lubricated.

-

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote -

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote -

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

-

2024-06-05Can the Angle of the Ballistic Separator Be Adjusted?Ballistic separator is a type of mechanical sorting device used primarily in the recycling industry to separate materials based on their physical properties. It...

-

2024-08-12The Advantages of Horizontal Baling TechnologyA horizontal baler, also known as a horizontal baling machine, is a piece of equipment used for compressing materials and wrapping them into bales. This process...

-

2024-06-05Waste Trommel And Copmost TrommelHowever, it's important to choose the right type of drum screen based on your specific needs. Today, Kevin from Zhongcheng Company will explain the differences...

-

2024-08-16Crop straw double shaft shredderApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...

-

2023-01-12Double-Shaft ShredderThe Double-shaft shredder is a widely used industrial shredder that efficiently processes various mixed waste materials, such as construction waste, industrial ...