Efficient compression and recovery: the wide range of applications and advantages of compact balers

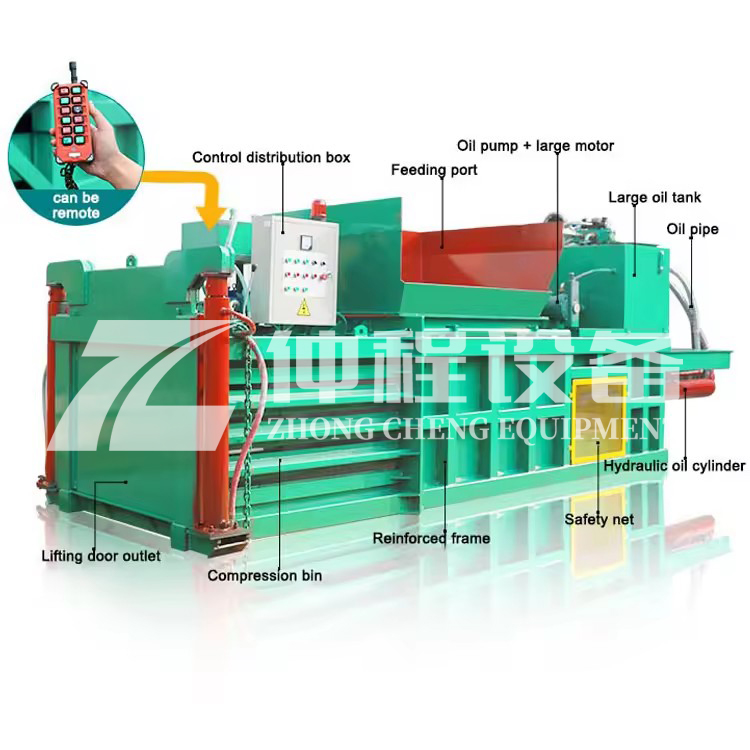

Introduction to Compacting Baling Press Machine

A Compacting Baling Press Machine, also known as a compactor baling machine, is a vital piece of equipment used in waste management, recycling, and manufacturing industries. It is designed to compress various materials into dense, manageable bales, making them easier to handle, store, and transport. This machine is particularly useful for reducing the volume of waste and improving operational efficiency.

Working Principle

The working principle of a compacting baling press machine involves several key steps:

- Feeding: The material to be baled is fed into the machine, either manually or through a conveyor system.

- Compaction: A powerful hydraulic or mechanical ram compresses the material into a dense form within a chamber.

- Baling: The compressed material is tied together using wire, string, or straps to maintain its shape as a bale.

Ejection: The bale is then ejected from the machine, typically through a side door or a conveyor system, ready for storage or transportation.

Advantages

- Volume Reduction: Significantly reduces the volume of materials, saving space in storage and transportation.

- Cost Efficiency: Reduces transportation and disposal costs by minimizing the volume of waste.

- Environmental Impact: Facilitates recycling and waste reduction, contributing to more sustainable practices.

- Safety and Cleanliness: Keeps the workplace tidy and safe by containing loose materials.

- Versatility: Can handle a wide range of materials, including paper, cardboard, plastics, metals, and textiles.

Automation: Many models offer automated features, such as automatic feeding and tying, which enhance efficiency and reduce labor costs.

Application Areas

Compacting baling press machines find applications in various industries:

- Waste Management: For processing and disposing of municipal solid waste.

- Recycling Facilities: To prepare materials for recycling, such as paper, cardboard, and plastics.

- Manufacturing Plants: For managing industrial waste and by-products, such as metal scraps and packaging materials.

- Retail and Distribution Centers: For compressing packaging waste, such as cardboard boxes and plastic wrap.

- Agriculture: For baling hay, straw, and other agricultural products.

- Textile Industry: For compressing textile waste, such as fabric scraps and old clothing.

-

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote -

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote -

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

-

2023-01-12WindshifterWindshifter (Air Drum Separator ) is the ideal solution for separating all kind of waste types into two fractions, heavy and light. The robust construction and ...

-

2023-01-12Apron FeedersApron Feeder is a conveyor manufactured from steel plates driven by steel chains wearing on steel surfaces. They are a robust design manufactured for durability...

-

2024-06-08Solutions for Jaw Crusher ProblemsJaw crusher is widely used in mining, smelting, building materials, highways, railways, water conservancy and chemical industries. The maximum compressive stren...

-

2024-07-09Recycling Balers-Safe,Easy-To-Use and affordableThe operating principle of a strapping machine primarily involves the following steps:1.Item Positioning:Firstly, the item to be strapped must be placed accurat...

-

2024-08-05Hot-sell Coconut Shredderworking principleCoconut shell shredder usually uses the force generated by cone and spiral to evenly squeeze the coconut meat in the grinding chamber between t...