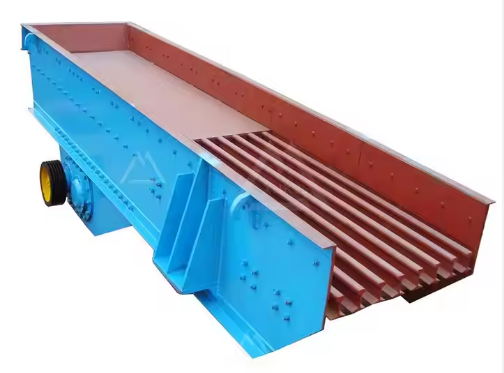

High Stroke Vibrating Feeder

Cutting edge vibratory technology for enhanced material presentation

Challenged by our customers to do more within a limited footprint, the

High Stroke Feeder (HSF) is developed to create separation,

improve on purity / recovery and increase the bottom line.

The HSF vibratory feeders improve on the presentation and recovery of various commodities

by putting more energy into the material, thereby increasing separation of the various particles.

In addition this spreads the materials across the width of the unit thereby resulting in enhanced

material presentation for your optical sorter.

HIGH STROKE FEEDER (HSF) PERFORMANCE ADVANTAGES:

High Stroke Creates Separation for Improved Purity

Faster Travel Speed = Better Material Separation = Optimal Recovery

More Energy Transmitted To the Material

Full Width Spread in Shorter Length

Lower Initial and Operating Costs

Dynamic Response to Negate Surge Loads

Up to 2/3 Less HP required to operate

OPTIONAL HSF FEATURES:

Specifically Engineered For the Industry

Optional Balanced Design Base

OEM Specific Models

Foot, Suspension or Combination Mounted Models

Mild Steel, Stainless Steel, Abrasion Resistant Steel Construction

| Model | Trough size(mm) | Max feed size(mm) | Capacity (t/h) | Motor Power (kw) |

| ZSW-650*2500 | 650*2500 | 560 | 50-80 | 5.5 |

| ZSW-850*3000 | 850*3000 | 780 | 80-120 | 7.5 |

| ZSW-960*3800 | 950*3800 | 820 | 120-210 | 11 |

| ZSW-1100*4200 | 1100*4200 | 1000 | 200-430 | 15 |

| ZSW-1100*4900 | 1100*4900 | 1000 | 280-500 | 15 |

| ZSW-1300*4900 | 1300*4900 | 1100 | 450-600 | 22 |

| ZSW-1500*6000 | 1500*6000 | 1280 | 550-1200 | 30 |

| ZSW-1800*6000 | 1800*6000 | 1350 | 600-1200 | 37 |

-

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote -

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote -

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

-

2024-04-13Wobbler FeederWobbler feeder is a type of feeding equipment that uses rotating elliptical bars, known as wobblers, to separate materials based on size and type before they re...

-

2024-08-20A rubber double shaft shredderExamples of Specific Models:GDB Series Biomass Shredder: Although primarily designed for biomass materials, this model can also be configured to handle various ...

-

2024-07-16Drum screen garbage processing machine for msw recyclingManaging municipal solid waste (MSW) efficiently is crucial for urban areas. Drum screen garbage processing machines are a game-changer in this field. They ensu...

-

2023-01-12Vibrating ScreenVibrating screen is a mechanical device used to separate materials into different sizes and grades by vibrating them through a mesh or screen. This equipment is...

-

2024-06-09Drum Screen RecyclingDrum screen machines are primarily used for material screening, helping to sort and recycle municipal solid waste and screen landfill waste. Their efficiency an...