Trommel screen construction waste sorting equipment

Introduction

In the modern era of construction and development, the management of construction waste has become a significant challenge. With the increasing emphasis on sustainability and environmental conservation, effective waste sorting and recycling processes are crucial. One of the most efficient pieces of equipment for sorting construction waste is the trommel screen. This article explores the workings, benefits, and applications of trommel screens in construction waste sorting.

![A}F$U09F{A~OWNEN]Y@6$$0.jpg](/uploads/allimg/20240715/1-240G5094605248.jpg)

What is a Trommel Screen?

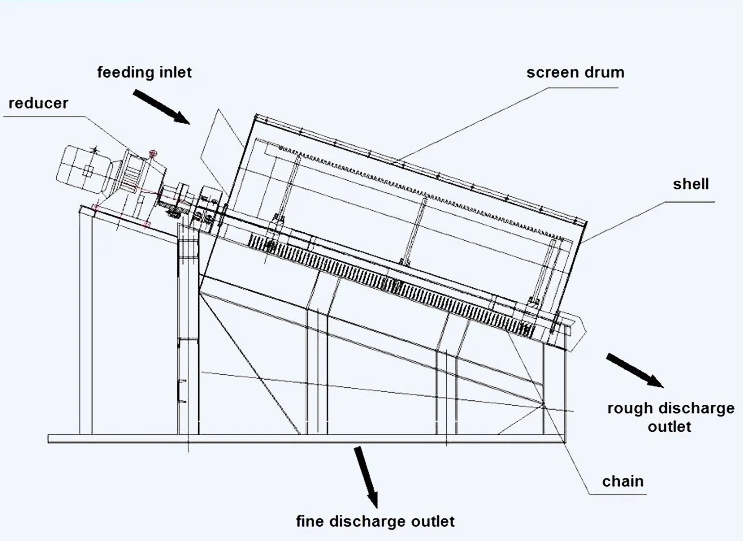

A trommel screen, also known as a rotary screen, is a mechanical screening machine used to separate materials. It consists of a cylindrical drum that rotates and is typically inclined. As the drum rotates, the material is lifted and then falls back down, which helps in breaking down the material and separating it based on size.

Key Features of Trommel Screens

Rotating Drum: The cylindrical drum is the core component where the sorting happens. It is perforated with holes of varying sizes to allow materials to pass through based on their dimensions.

Inclination: The drum is set at an angle to facilitate the movement of materials from one end to the other, aiding in the separation process.

Material Feed: Construction waste is fed into the drum, usually at the higher end. The material is then carried along the length of the drum by the rotation and inclination.

Screening Mechanism: As the drum rotates, materials that are smaller than the holes in the screen will fall through, while larger materials will continue to move along the drum and eventually exit at the other end.

How Trommel Screens Work

The trommel screen operates on a simple yet effective principle. Construction waste is introduced into the drum at one end. The drum, inclined at a slight angle, rotates continuously. As the drum turns, the waste is lifted and dropped, causing the smaller particles to pass through the perforations in the drum, while larger pieces continue to move towards the discharge end.

The angle of inclination and the rotation speed are critical parameters that determine the efficiency of the sorting process. Adjusting these parameters allows operators to optimize the separation process for different types of construction waste.

Benefits of Using Trommel Screens for Construction Waste Sorting

Efficient Separation: Trommel screens can efficiently separate materials of different sizes, which is crucial in recycling processes where precision is required.

Versatility: They can handle a variety of materials, including soil, gravel, sand, and construction waste, making them versatile for different applications.

High Throughput: These screens can process large volumes of material quickly, enhancing the overall productivity of the recycling operation.

Low Maintenance: Trommel screens are generally robust and durable, requiring minimal maintenance compared to other screening equipment.

Cost-Effective: Due to their efficiency and low maintenance requirements, trommel screens can be a cost-effective solution for sorting construction waste.

Reduced Environmental Impact: By facilitating the recycling and reuse of construction materials, trommel screens contribute to reducing the environmental footprint of construction projects.

Applications in Construction Waste Sorting

Separation of Soil and Debris: Trommel screens can separate soil from larger debris such as bricks and concrete pieces. This separation is vital for reclaiming clean soil for reuse in landscaping or as fill material.

Aggregate Recycling: They can be used to sort and clean aggregates, which can then be reused in construction projects. Recycled aggregates are often used in road construction, concrete production, and other construction applications.

Composting: In addition to construction waste, trommel screens can also be used for composting, helping to separate organic materials from inorganic ones. This process is particularly useful in urban areas where green waste is mixed with construction debris.

Landfill Diversion: By effectively sorting construction waste, trommel screens can help divert a significant portion of waste from landfills. This diversion reduces the strain on landfill sites and promotes more sustainable waste management practices.

Resource Recovery: The sorted materials, such as metals, plastics, and wood, can be recovered and sent for further processing or recycling. This recovery not only conserves resources but also generates economic value from waste materials.

Conclusion

Trommel screen use is in large-scale construction projects where vast amounts of waste are generated. For instance, during the demolition and reconstruction of urban infrastructure, a trommel screen can be employed to sort and recycle concrete, asphalt, and other construction materials. The sorted materials can then be reused on-site, reducing the need for new raw materials and minimizing the project's environmental impact.

In another case, a recycling facility specializing in construction waste implemented trommel screens to streamline their sorting process. The facility reported a significant increase in the efficiency of material recovery, leading to higher recycling rates and lower operational costs.

-

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote -

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote -

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

-

2023-01-13Bag OpenerBag opener or bag opener system is a mechanical device used to automatically open and empty bags containing bulk materials. This system is commonly used in indu...

-

2024-05-29Landfill stale garbage screening projectAfter communicating with our domestic customers in Shandong Province, we learned that he needed to dispose of the garbage in the landfill through excavation, sc...

-

2023-01-18Metal BalerMetal baler, specifically a hydraulic metal baler, is a machine designed to compress scrap metal into dense, manageable bales. This equipment is widely used in ...

-

2025-03-03Mini Copper Wire GranulatorThe copper wire granulator machine is a device specially used to process waste wires and cables. Its main function is to separate the copper and plastic in the ...

-

2024-08-28Scrap rubber product shredderThe shredder of waste rubber products not only helps to reduce environmental pollution, but also improves the reuse rate of waste rubber, which is one of the im...