High volume centrifugal windshifter domestic waste pipeline air drum separator

Windshifter introduction:

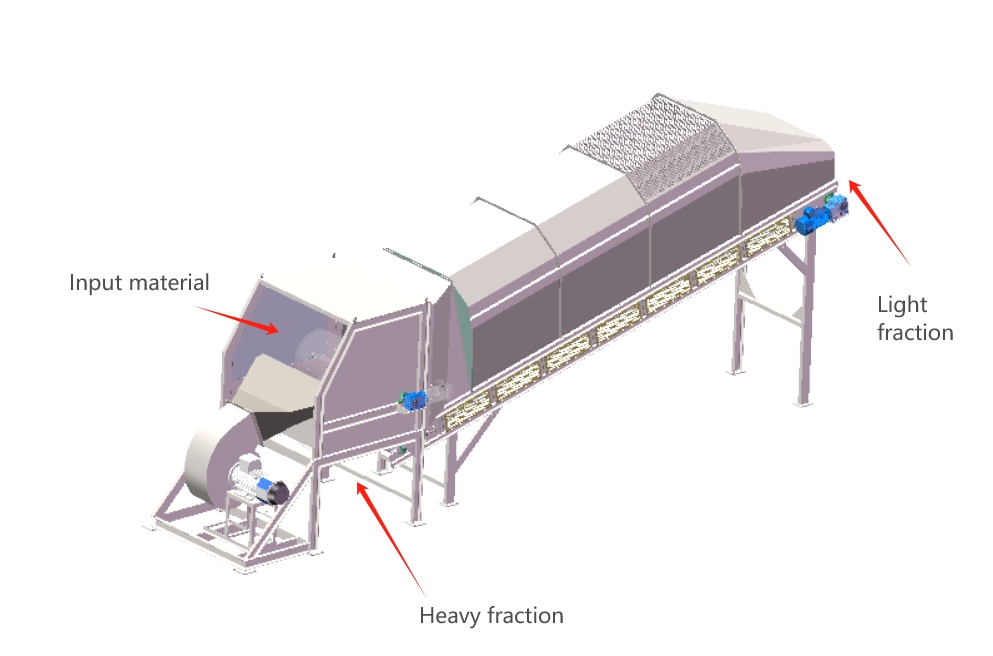

The windshifter uses the principle of aerodynamics to separate the light and small materials in materials such as domestic garbage and construction solid waste under the joint action of controllable positive pressure airflow and negative pressure airflow, and enters the sedimentation chamber to separate the materials from the air. The feed conveyor adopts frequency conversion control, which can be matched with the air volume, wind speed and wind pressure, and automatically adjusted according to the characteristics of the material composition. The exhaust pipe is equipped with a dust removal and deodorization connection port to effectively control the pollution to the environment.

Windshifter structure:

The windshifter usually consists of a feed port, a fan, a screen, a collection tank and other parts. The feed port introduces the material into the machine, and the fan accelerates the air to a certain speed and evenly distributes it to the internal space of the machine through the screen. The material is therefore affected by the wind, the lighter material is blown away, and the heavier material will be blocked by the screen and finally fall into the collection tank.

Windshifter working principle:

The working principle of the windshifter is mainly to use the aerodynamic characteristics of the material for screening and separation. The wind blows away the light materials and blocks the heavy materials on the surface of the screen. Through continuous vibration and screening, materials of different particle sizes are finally separated.

Windshifter advantages:

The windshifter has the advantages of simple structure, convenient operation, easy maintenance, low energy consumption, and good separation effect. Especially when processing a large amount of materials, the air separator can efficiently separate materials of different particle sizes and improve production efficiency.

Usage scenarios:

The windshifter is widely used in building materials, mining, food, medicine and other industries for screening and separation of granular or powdered materials. For example, in the building materials industry, the air separator can be used to separate the light materials in concrete and improve the quality of concrete; in the food industry, the windshifter can be used to screen out impurities and fragments in tea to ensure the quality of tea.

In short, as an efficient separation and screening equipment, the windshifter is widely used in various fields. Through its simple, easy to operate and efficient characteristics, it can help enterprises improve production efficiency, reduce production costs and improve product quality.

-

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote -

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote -

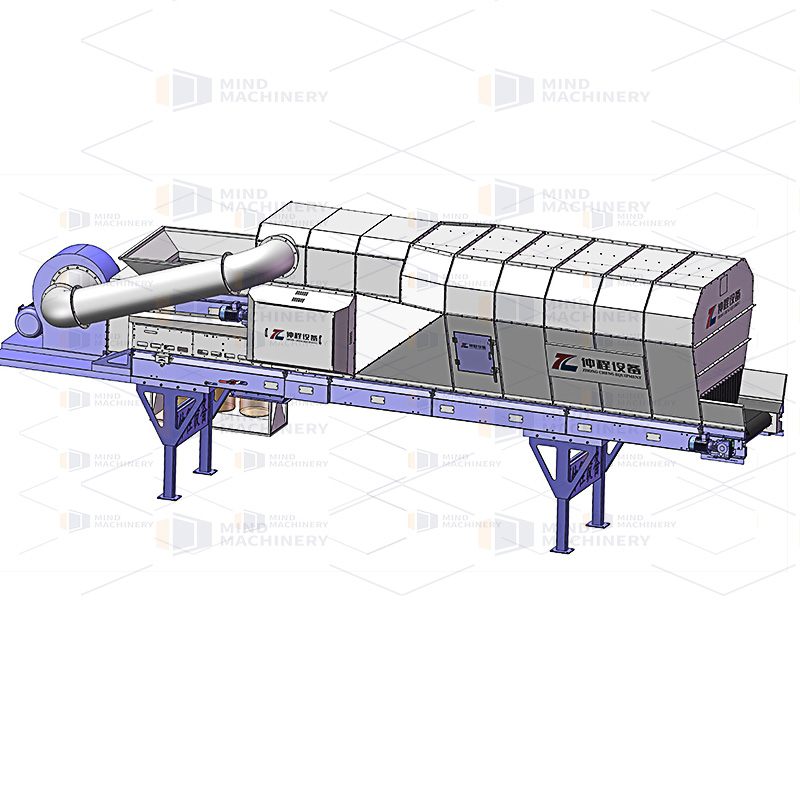

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

-

2024-08-06Plastic double shaft shredderOperation:Feeding: The plastic material is fed into the shredder through the infeed system.Shredding: As the material enters the shredding chamber, the rotating...

-

2024-05-18Mobile Jaw Crusher PlantMobile jaw crushing station is a novel rock crushing equipment, also known as mobile crushing station. The purpose of its design concept is to stand from the cu...

-

2024-04-13Vibrating FeederA vibrating feeder is a mechanical device used to convey materials, typically in bulk, from one location to another in a controlled manner. This equipment is co...

-

2023-01-12WindshifterWindshifter (Air Drum Separator ) is the ideal solution for separating all kind of waste types into two fractions, heavy and light. The robust construction and ...

-

2024-04-13Wobbler FeederWobbler feeder is a type of feeding equipment that uses rotating elliptical bars, known as wobblers, to separate materials based on size and type before they re...